PhD Thesis Arne Lüker final version V4 - Cranfield University

PhD Thesis Arne Lüker final version V4 - Cranfield University

PhD Thesis Arne Lüker final version V4 - Cranfield University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sol-Gel derived Ferroelectric Thin Films for Voltage Tunable Applications<br />

deposited on SiO2/Si substrates under different annealing conditions, the surface of the<br />

films was found to be smooth without any discontinuities in terms of crazing and<br />

microcracks, see Fig. 7.4, 7.11.<br />

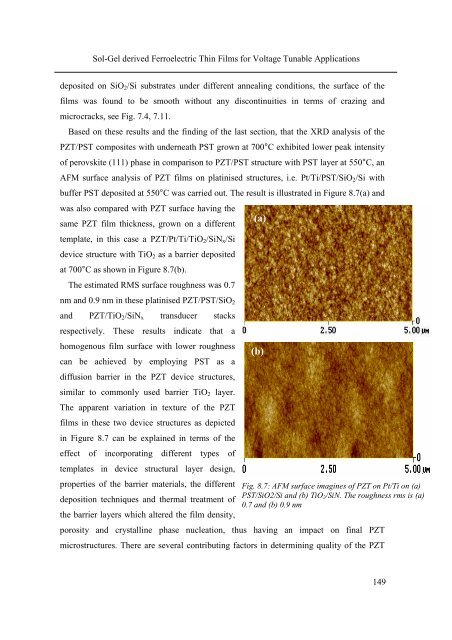

Based on these results and the finding of the last section, that the XRD analysis of the<br />

PZT/PST composites with underneath PST grown at 700°C exhibited lower peak intensity<br />

of perovskite (111) phase in comparison to PZT/PST structure with PST layer at 550°C, an<br />

AFM surface analysis of PZT films on platinised structures, i.e. Pt/Ti/PST/SiO2/Si with<br />

buffer PST deposited at 550°C was carried out. The result is illustrated in Figure 8.7(a) and<br />

was also compared with PZT surface having the<br />

same PZT film thickness, grown on a different<br />

template, in this case a PZT/Pt/Ti/TiO2/SiNx/Si<br />

device structure with TiO2 as a barrier deposited<br />

at 700°C as shown in Figure 8.7(b).<br />

The estimated RMS surface roughness was 0.7<br />

nm and 0.9 nm in these platinised PZT/PST/SiO2<br />

and PZT/TiO2/SiNx transducer stacks<br />

respectively. These results indicate that a<br />

homogenous film surface with lower roughness<br />

can be achieved by employing PST as a<br />

diffusion barrier in the PZT device structures,<br />

similar to commonly used barrier TiO2 layer.<br />

The apparent variation in texture of the PZT<br />

films in these two device structures as depicted<br />

in Figure 8.7 can be explained in terms of the<br />

effect of incorporating different types of<br />

templates in device structural layer design,<br />

properties of the barrier materials, the different<br />

deposition techniques and thermal treatment of<br />

the barrier layers which altered the film density,<br />

porosity and crystalline phase nucleation, thus having an impact on <strong>final</strong> PZT<br />

microstructures. There are several contributing factors in determining quality of the PZT<br />

(a)<br />

(b)<br />

Fig. 8.7: AFM surface imagines of PZT on Pt/Ti on (a)<br />

PST/SiO2/Si and (b) TiO2/SiN. The roughness rms is (a)<br />

0.7 and (b) 0.9 nm<br />

149