Advanced Wind Turbine Program Next Generation Turbine ... - NREL

Advanced Wind Turbine Program Next Generation Turbine ... - NREL

Advanced Wind Turbine Program Next Generation Turbine ... - NREL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

possibly an improvement in generator efficiency. As a result, GE did not give significant consideration<br />

to this option.<br />

GE, instead, examined the option of connecting squirrel cage or synchronous machines directly<br />

to the grid and eliminating the need for power converters. Squirrel cage asynchronous generators<br />

and wound rotor synchronous generators can be purchased for approximately 60%–70% of the<br />

cost of a wound rotor asynchronous machine. The converter cost is eliminated. The cost of a 4pole<br />

or 6-pole permanent magnet synchronous machine was not thoroughly investigated by GE,<br />

as it was decided that the machine would be more expensive than a wound rotor synchronous<br />

generator. On the performance side, however, some energy capture is lost from fixed speed operation.<br />

This energy capture was estimated by GE personnel at approximately 3%. The impact<br />

on COE is negligible, as the reduction in cost is offset by a reduction in energy capture. As a<br />

result, GE decided not to pursue these fixed speed options further. These fixed-speed options<br />

also lack the ability to provide dynamic VAR control offered by the baseline system.<br />

2.1.1.4 Multiple Conventional-Speed Generators<br />

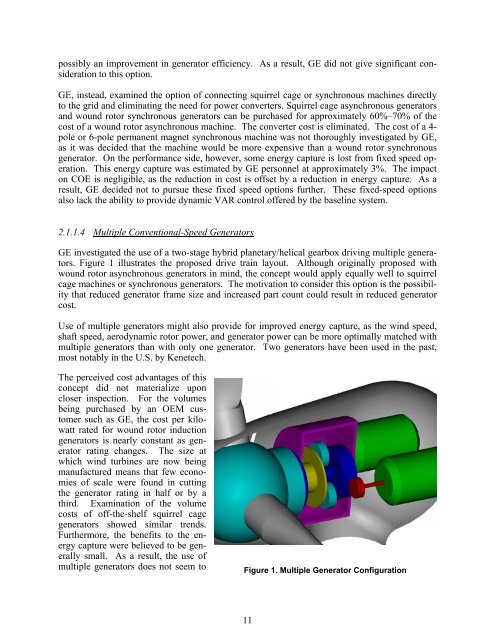

GE investigated the use of a two-stage hybrid planetary/helical gearbox driving multiple generators.<br />

Figure 1 illustrates the proposed drive train layout. Although originally proposed with<br />

wound rotor asynchronous generators in mind, the concept would apply equally well to squirrel<br />

cage machines or synchronous generators. The motivation to consider this option is the possibility<br />

that reduced generator frame size and increased part count could result in reduced generator<br />

cost.<br />

Use of multiple generators might also provide for improved energy capture, as the wind speed,<br />

shaft speed, aerodynamic rotor power, and generator power can be more optimally matched with<br />

multiple generators than with only one generator. Two generators have been used in the past,<br />

most notably in the U.S. by Kenetech.<br />

The perceived cost advantages of this<br />

concept did not materialize upon<br />

closer inspection. For the volumes<br />

being purchased by an OEM customer<br />

such as GE, the cost per kilowatt<br />

rated for wound rotor induction<br />

generators is nearly constant as generator<br />

rating changes. The size at<br />

which wind turbines are now being<br />

manufactured means that few economies<br />

of scale were found in cutting<br />

the generator rating in half or by a<br />

third. Examination of the volume<br />

costs of off-the-shelf squirrel cage<br />

generators showed similar trends.<br />

Furthermore, the benefits to the energy<br />

capture were believed to be generally<br />

small. As a result, the use of<br />

multiple generators does not seem to Figure 1. Multiple Generator Configuration<br />

11