Advanced Wind Turbine Program Next Generation Turbine ... - NREL

Advanced Wind Turbine Program Next Generation Turbine ... - NREL

Advanced Wind Turbine Program Next Generation Turbine ... - NREL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Power Production [kW<br />

1,500<br />

1,000<br />

500<br />

0<br />

Steady <strong>Wind</strong>s<br />

9% Turbulence<br />

0 5 10 15 20 25 30<br />

<strong>Wind</strong> Speed [m/s]<br />

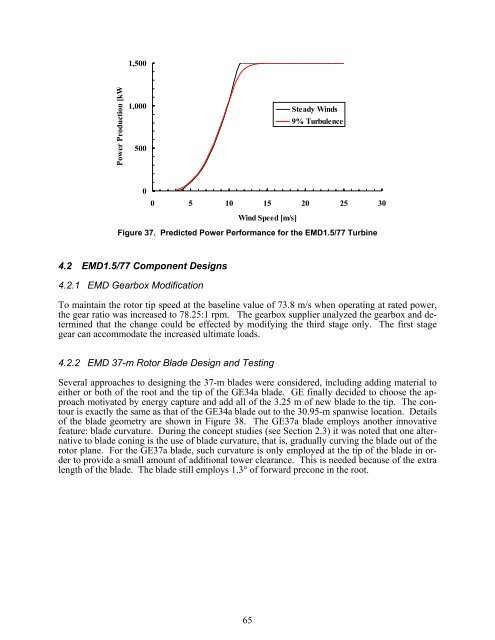

Figure 37. Predicted Power Performance for the EMD1.5/77 <strong>Turbine</strong><br />

4.2 EMD1.5/77 Component Designs<br />

4.2.1 EMD Gearbox Modification<br />

To maintain the rotor tip speed at the baseline value of 73.8 m/s when operating at rated power,<br />

the gear ratio was increased to 78.25:1 rpm. The gearbox supplier analyzed the gearbox and determined<br />

that the change could be effected by modifying the third stage only. The first stage<br />

gear can accommodate the increased ultimate loads.<br />

4.2.2 EMD 37-m Rotor Blade Design and Testing<br />

Several approaches to designing the 37-m blades were considered, including adding material to<br />

either or both of the root and the tip of the GE34a blade. GE finally decided to choose the approach<br />

motivated by energy capture and add all of the 3.25 m of new blade to the tip. The contour<br />

is exactly the same as that of the GE34a blade out to the 30.95-m spanwise location. Details<br />

of the blade geometry are shown in Figure 38. The GE37a blade employs another innovative<br />

feature: blade curvature. During the concept studies (see Section 2.3) it was noted that one alternative<br />

to blade coning is the use of blade curvature, that is, gradually curving the blade out of the<br />

rotor plane. For the GE37a blade, such curvature is only employed at the tip of the blade in order<br />

to provide a small amount of additional tower clearance. This is needed because of the extra<br />

length of the blade. The blade still employs 1.3° of forward precone in the root.<br />

65