Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 Technical Fundamentals<br />

5.1 Installation<br />

5.2 <strong>Pipe</strong><br />

connection<br />

This <strong>Manual</strong> helps carrying out <strong>the</strong> optimal design <strong>of</strong> centrifugal pumps. We show you<br />

how to proceed to find <strong>the</strong> right pump.<br />

Install <strong>the</strong> pump in close vicinity to <strong>the</strong> tank or to ano<strong>the</strong>r source from which <strong>the</strong> liquid will<br />

be pumped. Make sure that as few as possible valves <strong>and</strong> bends are integrated in <strong>the</strong> pump‘s<br />

suction pipe, in order to keep <strong>the</strong> pressure drop as low as possible. Sufficient space around<br />

<strong>the</strong> pump provides <strong>for</strong> easy maintenance work <strong>and</strong> inspection. <strong>Pumps</strong> equipped with a<br />

conventional base plate <strong>and</strong> motor base should be mounted on a steady foundation <strong>and</strong> be<br />

precisely aligned prior commissioning.<br />

<strong>GEA</strong> Tuchenhagen pumps are equipped with pipe connections that are adaped to <strong>the</strong> flow<br />

rate. Very small pipe dimensions result in low cost on one h<strong>and</strong>, but on <strong>the</strong> o<strong>the</strong>r h<strong>and</strong> put<br />

<strong>the</strong> safe, reliable <strong>and</strong> cavitation-free operation <strong>of</strong> <strong>the</strong> pump at risk.<br />

Practical experience has shown that identical connection diameters on a short suction pipe<br />

are beneficial, however, always keep an eye on <strong>the</strong> fluid velocity. Excepted <strong>the</strong>re<strong>of</strong> are long<br />

suction pipes with integrated valves <strong>and</strong> bends. In this case <strong>the</strong> suction pipe should be by one<br />

size larger, in order to reduce <strong>the</strong> pressure drop.<br />

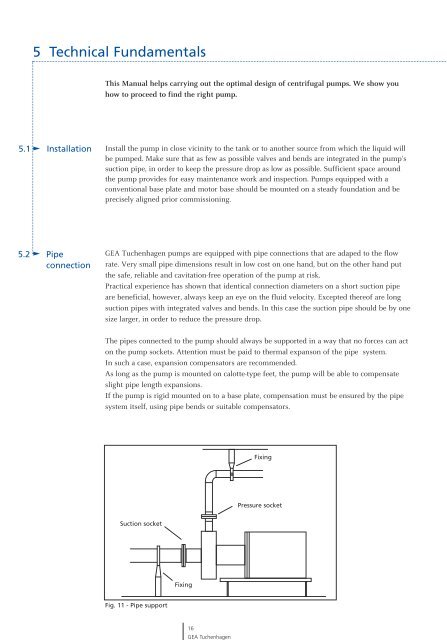

The pipes connected to <strong>the</strong> pump should always be supported in a way that no <strong>for</strong>ces can act<br />

on <strong>the</strong> pump sockets. Attention must be paid to <strong>the</strong>rmal expanson <strong>of</strong> <strong>the</strong> pipe system.<br />

In such a case, expansion compensators are recommended.<br />

As long as <strong>the</strong> pump is mounted on calotte-type feet, <strong>the</strong> pump will be able to compensate<br />

slight pipe length expansions.<br />

If <strong>the</strong> pump is rigid mounted on to a base plate, compensation must be ensured by <strong>the</strong> pipe<br />

system itself, using pipe bends or suitable compensators.<br />

Suction socket<br />

Fig. 11 - <strong>Pipe</strong> support<br />

Fixing<br />

16<br />

<strong>GEA</strong> Tuchenhagen<br />

Fixing<br />

Pressure socket