Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7.5 Result<br />

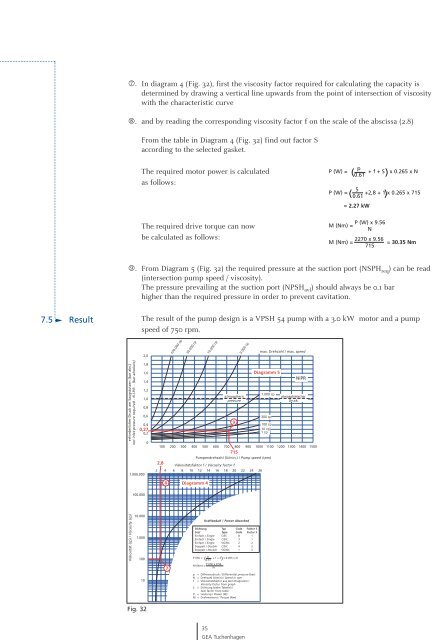

7. In diagram 4 (Fig. 32), first <strong>the</strong> viscosity factor required <strong>for</strong> calculat ing <strong>the</strong> capacity is<br />

determined by draw ing a vertical line upwards from <strong>the</strong> point <strong>of</strong> intersection <strong>of</strong> viscosity<br />

with <strong>the</strong> characteristic curve<br />

8. <strong>and</strong> by reading <strong>the</strong> corres ponding viscosity factor f on <strong>the</strong> scale <strong>of</strong> <strong>the</strong> abscissa (2.8)<br />

From <strong>the</strong> table in Diagram 4 (Fig. 32) find out factor S<br />

according to <strong>the</strong> selected gasket.<br />

The required motor power is calculated<br />

as follows:<br />

The required drive torque can now<br />

be calculated as follows:<br />

9. From Diagram 5 (Fig. 32) <strong>the</strong> required pressure at <strong>the</strong> suction port (NSPH req) can be read<br />

(intersection pump speed / viscosity).<br />

The pressure prevailing at <strong>the</strong> suction port (NPSH avl) should always be 0.1 bar<br />

higher than <strong>the</strong> required pres sure in order to prevent cavitation.<br />

er<strong>for</strong>derlicher Druck am Saugstutzen (bar abs.)<br />

net inlet pressure required - N.I.P.R. - (bar absolute)<br />

1.000.000<br />

Viskosität (cp) / Viscosity (cp)<br />

100.000<br />

10.000<br />

The result <strong>of</strong> <strong>the</strong> pump design is a VPSH 54 pump with a 3.0 kW motor <strong>and</strong> a pump<br />

speed <strong>of</strong> 750 rpm.<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,6<br />

0,4<br />

0,27<br />

0,2<br />

0<br />

1.000<br />

100<br />

10<br />

Fig. 32<br />

atmospheric<br />

pressure<br />

100 200 300 400 500 600 700 800<br />

715<br />

900 1000 1100 1200 1300 1400 1500<br />

2,8<br />

Pumpendrehzahl (U/min.) / Pump speed (rpm)<br />

Viskositätsfaktor f / Viscosity factor f<br />

2 4 6 8 10 12 14 16 18 20 22 24 26<br />

8<br />

7<br />

100.000 cp<br />

30.000 cp<br />

Diagramm 4<br />

10.000 cp<br />

9<br />

3.000 cp<br />

Kraftbedarf / Power Absorbed<br />

Dichtung Typ Code Faktor S<br />

Seal Type Code Factor S<br />

Einfach / Single C/SS 8 1<br />

Einfach / Single C/SIC 3 1<br />

Einfach / Single SIC/SIC 2 2<br />

Doppelt / Double C/SIC 4 2<br />

Doppelt / Double SIC/SIC 1 3<br />

p<br />

P (W) = ( + f + S x 0.455 x N<br />

0.61 )<br />

P (W) x 9.56<br />

M (Nm) =<br />

N<br />

p = Differenzdruck / Differential pressure (bar)<br />

N = Drehzahl (U/min) / Speed in rpm<br />

f = Viskositätsfaktor aus dem Diagramm /<br />

Viscosity factor from graph<br />

S = Dichtung (siehe Tabelle) /<br />

Seal factor from table<br />

P = Leistung / Power (W)<br />

M = Drehmoment / Torque (Nm)<br />

35<br />

<strong>GEA</strong> Tuchenhagen<br />

max. Drehzahl / max. speed<br />

Diagramm 5<br />

1.000 cp<br />

300 cp<br />

100 cp<br />

10 cp<br />

1 cp<br />

NIPR<br />

atmosphärischer<br />

Druck<br />

Technische Daten / Application Data<br />

Max. Wellendrehmoment /<br />

Max. input shaft torque (Nm) 150<br />

Max. radiale Wellenbelastung /<br />

Max. shaft radial load (N) 2250<br />

Max. Partikelgröße (weich) /<br />

Max. s<strong>of</strong>t particle dia. (mm) 15<br />

Verdrängung / Displacement (cc/rev) 455<br />

Verdrängung /<br />

Displacement (litres/100revs) 45.5<br />

Physikalische Daten / Physical Data<br />

Gewicht der Pumpe ohne Antrieb /<br />

Bareshaft pump weight (kg) 35<br />

Ölvolumen / Oil capacity (cc) 1100<br />

Rückhaltevolumen /<br />

Hold up volume (cc) 820<br />

(horizontale Anschlüsse) /<br />

(horizontal ports)<br />

Anzugsmomente / Tightening Torques (Nm)<br />

Enddeckelbolzen / End cover bolts 20<br />

Rotorschrauben / Rotor retainer screws 55<br />

Rotorgehäuseschrauben /<br />

Rotor case screws 20<br />

Getriebedeckelschrauben /<br />

Gear cover screws 15<br />

Zahnradmuttern / Gear nuts 100<br />

Rotorzugstangenschrauben VPSU /<br />

Rotor tie rod nuts 40<br />

Rotortoleranzen / Rotor Clearances (mm)<br />

Vorne, Rotor zum Deckel /<br />

Front, rotor to end cover 0.15<br />

Radial, Rotor zum Rotorgehäuse /<br />

Radial, rotor to rotor case 0.25<br />

Rotor zu Rotor / Mesh, lobe to lobe - min 0.20<br />

p<br />

P (W) = 0.61 + f + S x 0.265 x N<br />

( )<br />

5<br />

P (W) = +2,8 + 1 x 0.265 x 715<br />

0.61<br />

( )<br />

= 2.27 kW<br />

P (W) x 9.56<br />

M (Nm) =<br />

N<br />

M (Nm) = 2270 x 9.56 = 30.35 Nm<br />

715