Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6.4 Pumping <strong>of</strong><br />

viscous media<br />

6.4.1 Correction <strong>for</strong><br />

high viscosities<br />

In <strong>the</strong> previous example (Chapter 6.1) water served as pumping medium.<br />

In practice media o<strong>the</strong>r than water are conveyed. In this respect viscosity is a factor that<br />

must be taken into account <strong>for</strong> <strong>the</strong> calculation <strong>and</strong> design <strong>of</strong> <strong>the</strong> pump.<br />

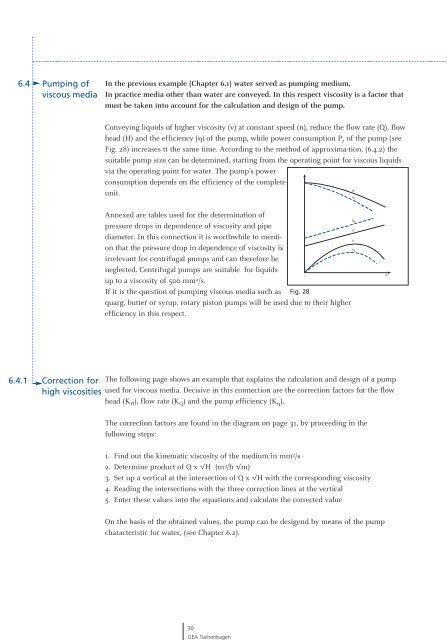

Conveying liquids <strong>of</strong> higher viscosity (ν) at constant speed (n), reduce <strong>the</strong> flow rate (Q), flow<br />

head (H) <strong>and</strong> <strong>the</strong> efficiency (η) <strong>of</strong> <strong>the</strong> pump, while power consumption Pz <strong>of</strong> <strong>the</strong> pump (see<br />

Fig. 28) increases tt <strong>the</strong> same time. According to <strong>the</strong> method <strong>of</strong> approxima-tion, (6.4.2) <strong>the</strong><br />

suitable pump size can be determined, starting from <strong>the</strong> operating point <strong>for</strong> viscous liquids<br />

via <strong>the</strong> operating point <strong>for</strong> water. The pump’s power<br />

consumption depends on <strong>the</strong> efficiency <strong>of</strong> <strong>the</strong> complete<br />

H<br />

unit.<br />

Annexed are tables used <strong>for</strong> <strong>the</strong> determination <strong>of</strong><br />

pressure drops in dependence <strong>of</strong> viscosity <strong>and</strong> pipe<br />

diameter. In this connection it is worthwhile to mention<br />

that <strong>the</strong> pressure drop in dependence <strong>of</strong> viscosity is<br />

irrelevant <strong>for</strong> centrifugal pumps <strong>and</strong> can <strong>the</strong>re<strong>for</strong>e be<br />

neglected. Centrifugal pumps are suitable <strong>for</strong> liquids<br />

up to a viscosity <strong>of</strong> 500 mm2/s. picture 5<br />

If it is <strong>the</strong> question <strong>of</strong> pumping viscous media such as Fig. 28<br />

quarg, butter or syrup, rotary piston pumps will be used due to <strong>the</strong>ir higher<br />

efficiency in this respect.<br />

The following page shows an example that explains <strong>the</strong> calculation <strong>and</strong> design <strong>of</strong> a pump<br />

used <strong>for</strong> viscous media. Decisive in this connection are <strong>the</strong> correction factors <strong>for</strong> <strong>the</strong> flow<br />

head (K H), flow rate (K Q) <strong>and</strong> <strong>the</strong> pump efficiency (K η).<br />

The correction factors are found in <strong>the</strong> diagram on page 31, by proceeding in <strong>the</strong><br />

following steps:<br />

1. Find out <strong>the</strong> kinematic viscosity <strong>of</strong> <strong>the</strong> medium in mm 2/s<br />

2. Determine product <strong>of</strong> Q x √H (m 3/h √m)<br />

3. Set up a vertical at <strong>the</strong> intersection <strong>of</strong> Q x √H with <strong>the</strong> corresponding viscosity<br />

4. Reading <strong>the</strong> intersections with <strong>the</strong> three correction lines at <strong>the</strong> vertical<br />

5. Enter <strong>the</strong>se values into <strong>the</strong> equations <strong>and</strong> calculate <strong>the</strong> corrected value<br />

On <strong>the</strong> basis <strong>of</strong> <strong>the</strong> obtained values, <strong>the</strong> pump can be desigend by means <strong>of</strong> <strong>the</strong> pump<br />

characteristic <strong>for</strong> water, (see Chapter 6.2).<br />

30<br />

<strong>GEA</strong> Tuchenhagen<br />

H z<br />

P z<br />

P<br />

h<br />

h z<br />

Q