Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

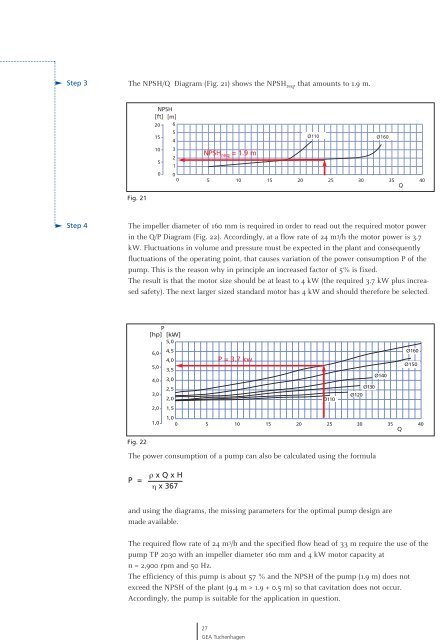

Step 3<br />

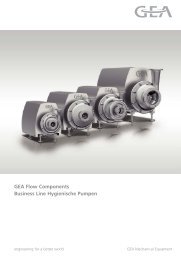

Step 4<br />

The NPSH/Q Diagram (Fig. 21) shows <strong>the</strong> NPSH req, that amounts to 1.9 m.<br />

Fig. 21<br />

The impeller diameter <strong>of</strong> 160 mm is required in order to read out <strong>the</strong> required motor power<br />

in <strong>the</strong> Q/P Diagram (Fig. 22). Accordingly, at a flow rate <strong>of</strong> 24 m 3/h <strong>the</strong> motor power is 3.7<br />

kW. Fluctuations in volume <strong>and</strong> pressure must be expected in <strong>the</strong> plant <strong>and</strong> consequently<br />

fluctuations <strong>of</strong> <strong>the</strong> operating point, that causes variation <strong>of</strong> <strong>the</strong> power consumption P <strong>of</strong> <strong>the</strong><br />

pump. This is <strong>the</strong> reason why in principle an increased factor <strong>of</strong> 5% is fixed.<br />

The result is that <strong>the</strong> motor size should be at least to 4 kW (<strong>the</strong> required 3.7 kW plus increased<br />

safety). The next larger sized st<strong>and</strong>ard motor has 4 kW <strong>and</strong> should <strong>the</strong>re<strong>for</strong>e be selected.<br />

Fig. 22<br />

The power consumption <strong>of</strong> a pump can also be calculated using <strong>the</strong> <strong>for</strong>mula<br />

P =<br />

NPSH<br />

[ft] [m]<br />

20 6<br />

5<br />

15<br />

4<br />

10 3<br />

2<br />

5<br />

1<br />

0 0<br />

0<br />

P<br />

[hp] [kW]<br />

5,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

4,5<br />

4,0<br />

3,5<br />

3,0<br />

2,5<br />

2,0<br />

1,5<br />

1,0<br />

0 5 10 15 20 25 30 35<br />

Q<br />

ρ x Q x H<br />

η x 367<br />

NPSH req = 1.9 m<br />

5 10 15 20 25 30 35<br />

P = 3.7 kw<br />

<strong>and</strong> using <strong>the</strong> diagrams, <strong>the</strong> missing parameters <strong>for</strong> <strong>the</strong> optimal pump design are<br />

made available.<br />

The required flow rate <strong>of</strong> 24 m 3 /h <strong>and</strong> <strong>the</strong> specified flow head <strong>of</strong> 33 m require <strong>the</strong> use <strong>of</strong> <strong>the</strong><br />

pump TP 2030 with an impeller diameter 160 mm <strong>and</strong> 4 kW motor capacity at<br />

n = 2,900 rpm <strong>and</strong> 50 Hz.<br />

The efficiency <strong>of</strong> this pump is about 57 % <strong>and</strong> <strong>the</strong> NPSH <strong>of</strong> <strong>the</strong> pump (1.9 m) does not<br />

exceed <strong>the</strong> NPSH <strong>of</strong> <strong>the</strong> plant (9.4 m > 1.9 + 0.5 m) so that cavitation does not occur.<br />

Accordingly, <strong>the</strong> pump is suitable <strong>for</strong> <strong>the</strong> application in question.<br />

27<br />

<strong>GEA</strong> Tuchenhagen<br />

Ø110 Ø160<br />

Ø110<br />

Ø130<br />

Ø120<br />

Ø140<br />

Q<br />

Ø160<br />

Ø150<br />

40<br />

40