Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6.3 Modification<br />

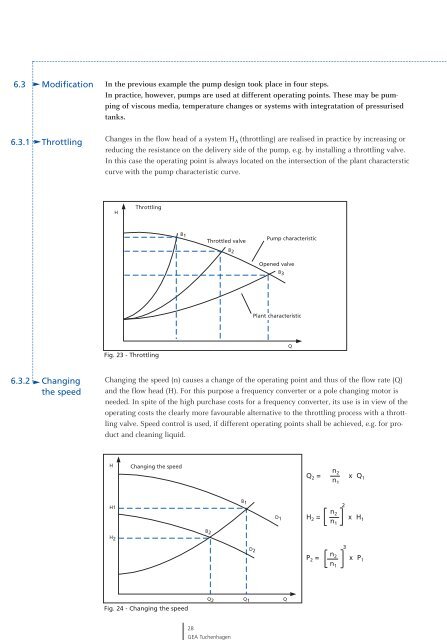

6.3.1 Throttling<br />

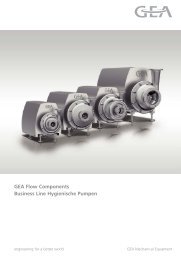

6.3.2 Changing<br />

<strong>the</strong> speed<br />

In <strong>the</strong> previous example <strong>the</strong> pump design took place in four steps.<br />

In practice, however, pumps are used at different operating points. These may be pumping<br />

<strong>of</strong> viscous media, temperature changes or systems with integratation <strong>of</strong> pressurised<br />

tanks.<br />

Changes in <strong>the</strong> flow head <strong>of</strong> a system H A (throttling) are realised in practice by increasing or<br />

reducing <strong>the</strong> resistance on <strong>the</strong> delivery side <strong>of</strong> <strong>the</strong> pump, e.g. by installing a throttling valve.<br />

In this case <strong>the</strong> operating point is always located on <strong>the</strong> intersection <strong>of</strong> <strong>the</strong> plant characterstic<br />

curve with <strong>the</strong> pump characteristic curve.<br />

H<br />

Drosselung Throttling<br />

Fig. 23 - Throttling<br />

B 1<br />

gedrosseltes Throttled valve Ventil<br />

B 2<br />

Changing <strong>the</strong> speed (n) causes a change <strong>of</strong> <strong>the</strong> operating point <strong>and</strong> thus <strong>of</strong> <strong>the</strong> flow rate (Q)<br />

<strong>and</strong> <strong>the</strong> flow head (H). For this purpose a frequency converter or a pole changing motor is<br />

needed. In spite <strong>of</strong> <strong>the</strong> high purchase costs <strong>for</strong> a frequency converter, its use is in view <strong>of</strong> <strong>the</strong><br />

operating costs <strong>the</strong> clearly more favourable alternative to <strong>the</strong> throttling process with a throttling<br />

valve. Speed control is used, if different operating points shall be achieved, e.g. <strong>for</strong> product<br />

<strong>and</strong> cleaning liquid.<br />

H<br />

H1<br />

H 2<br />

Drehzahländerung<br />

Changing <strong>the</strong> speed<br />

Fig. 24 - Changing <strong>the</strong> speed<br />

B 2<br />

28<br />

<strong>GEA</strong> Tuchenhagen<br />

B 1<br />

D 2<br />

Pump characteristic<br />

geöffnetes Opened valve<br />

Ventil<br />

B 3<br />

Plant characteristic<br />

D 1<br />

Q 2 Q 1 Q<br />

Q<br />

n2 Q2 = x Q1 n1 n2 n1 2<br />

H 2 = x H 1<br />

n2 n1 3<br />

P 2 = x P 1