Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Manual for the Design of Pipe Systems and Pumps - GEA ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7.3 Example Product data<br />

• Medium: Yeast<br />

• Temperature: t = 10°C<br />

• Viscosity: η = 100 cP<br />

• Density: ρ = 1,000 kg/m3 • Portion <strong>of</strong> particles none<br />

• Particle size none<br />

• Single acting mechanical seal in <strong>the</strong> pairing carbon against stainless steel<br />

Pumping data<br />

• Q = 300 l/min.<br />

• ∆p = 5 bar<br />

• NPSH: 0.4 bar abs.<br />

Selection <strong>of</strong> <strong>the</strong> pump size<br />

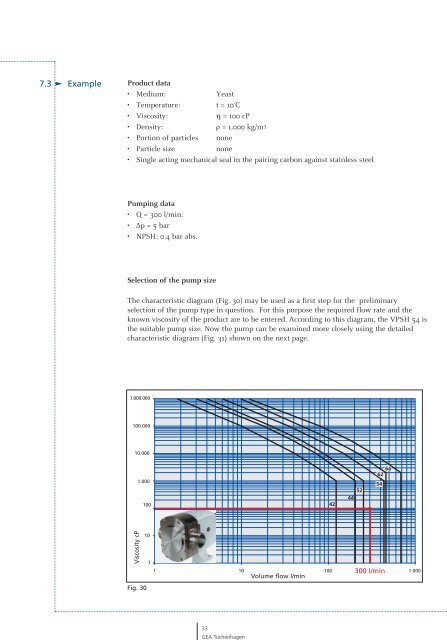

The characteristic diagram (Fig. 30) may be used as a first step <strong>for</strong> <strong>the</strong> preliminary<br />

selection <strong>of</strong> <strong>the</strong> pump type in question. For this purpose <strong>the</strong> required flow rate <strong>and</strong> <strong>the</strong><br />

known viscosity <strong>of</strong> <strong>the</strong> product are to be entered. According to this diagram, <strong>the</strong> VPSH 54 is<br />

<strong>the</strong> suit able pump size. Now <strong>the</strong> pump can be examined more closely using <strong>the</strong> detailed<br />

characteristic diagram (Fig. 31) shown on <strong>the</strong> next page.<br />

1.000.000<br />

100.000<br />

10.000<br />

Viscosity cP<br />

1.000<br />

Fig. 30<br />

100<br />

10<br />

1<br />

1 10 100 1.000<br />

Volume flow l/min<br />

33<br />

<strong>GEA</strong> Tuchenhagen<br />

42<br />

52<br />

44<br />

64<br />

62<br />

54<br />

300 l/min