- Page 1 and 2: THÈSE Pour l’obtention du Grade

- Page 3 and 4: Acknowledgements Acknowledgements T

- Page 5 and 6: Résumé __________________________

- Page 7 and 8: Nomenclature Nomenclature Roman tel

- Page 9 and 10: Nomenclature Subscripts tel-0062309

- Page 11 and 12: Contents tel-00623090, version 1 -

- Page 13 and 14: Contents 6.4. SYNGAS FUELLED-ENGINE

- Page 15 and 16: Introduction CHAPTER 1 INTRODUCTION

- Page 17 and 18: Introduction proves to have higher

- Page 19 and 20: Introduction Chapter 3 - Experiment

- Page 21 and 22: Bibliographic revision CHAPTER 2 BI

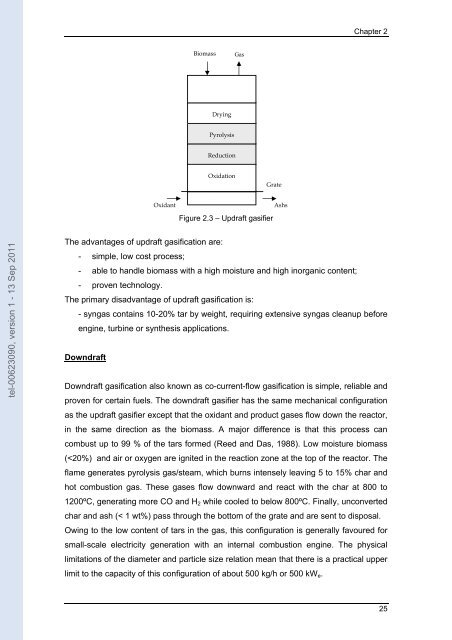

- Page 23 and 24: Bibliographic revision point today

- Page 25 and 26: Bibliographic revision - Boudouard

- Page 27: Bibliographic revision Table 2.1 -

- Page 31 and 32: Bibliographic revision Circulating

- Page 33 and 34: Bibliographic revision or eliminate

- Page 35 and 36: Bibliographic revision established

- Page 37 and 38: Bibliographic revision Hydrogen Hyd

- Page 39 and 40: Bibliographic revision of low moist

- Page 41 and 42: Bibliographic revision scrubbing an

- Page 43 and 44: Bibliographic revision suggests tha

- Page 45 and 46: Bibliographic revision 1 d( δ A) 1

- Page 47 and 48: Bibliographic revision Since n is

- Page 49 and 50: Bibliographic revision 2 ( rsr ) 2

- Page 51 and 52: Bibliographic revision This evoluti

- Page 53 and 54: Bibliographic revision The burning

- Page 55 and 56: Bibliographic revision δVG = − a

- Page 57 and 58: Bibliographic revision 2 1 − −

- Page 59 and 60: Bibliographic revision where the su

- Page 61 and 62: Bibliographic revision the stretche

- Page 63 and 64: Bibliographic revision burning velo

- Page 65 and 66: Experimental set ups and diagnostic

- Page 67 and 68: Experimental set ups and diagnostic

- Page 69 and 70: Experimental set ups and diagnostic

- Page 71 and 72: Experimental set ups and diagnostic

- Page 73 and 74: Experimental set ups and diagnostic

- Page 75 and 76: Experimental set ups and diagnostic

- Page 77 and 78: Experimental set ups and diagnostic

- Page 79 and 80:

Experimental set ups and diagnostic

- Page 81 and 82:

Experimental set ups and diagnostic

- Page 83 and 84:

Experimental set ups and diagnostic

- Page 85 and 86:

Experimental set ups and diagnostic

- Page 87 and 88:

Experimental set ups and diagnostic

- Page 89 and 90:

Chapter 4 CHAPTER 4 EXPERIMENTAL AN

- Page 91 and 92:

Chapter 4 4.1 Laminar burning veloc

- Page 93 and 94:

Chapter 4 4.1.1.1 Flame morphology

- Page 95 and 96:

Chapter 4 P i = 1.0 bar, Ti = 293 K

- Page 97 and 98:

Chapter 4 Figure 4.5 shows schliere

- Page 99 and 100:

Chapter 4 P i = 2.0 bar, T i = 293

- Page 101 and 102:

Chapter 4 Sn (m/s) 3.0 2.5 2.0 1.5

- Page 103 and 104:

Chapter 4 5 ms 10 ms 15 ms 20 ms 25

- Page 105 and 106:

Chapter 4 behaviour of the curves r

- Page 107 and 108:

Chapter 4 1.50 Sn (m/s) 1.25 1.00 0

- Page 109 and 110:

Chapter 4 0.5 0.4 φ =1.0 Su (m/s)

- Page 111 and 112:

Chapter 4 variation of the normaliz

- Page 113 and 114:

Chapter 4 4.1.1.6 Comparison with o

- Page 115 and 116:

Chapter 4 The values of laminar bur

- Page 117 and 118:

Chapter 4 Pressure (bar) 7 6 5 4 3

- Page 119 and 120:

Chapter 4 0.5 0.4 φ=1.2 Su (m/s) 0

- Page 121 and 122:

Chapter 4 0.3 φ=0.8 Su (m/s) 0.2 0

- Page 123 and 124:

Chapter 4 a minimum pressure to exp

- Page 125 and 126:

Chapter 4 Notice the similar behavi

- Page 127 and 128:

Chapter 4 A very good agreement bet

- Page 129 and 130:

Chapter 4 ( ) Q = h T − T (4.21)

- Page 131 and 132:

Chapter 4 tel-00623090, version 1 -

- Page 133 and 134:

Chapter 4 are tested and discussed.

- Page 135 and 136:

Chapter 4 7 500 Pressure (bar) 6 5

- Page 137 and 138:

Chapter 4 Pressure (bar) 7 6 5 4 3

- Page 139 and 140:

Chapter 4 4.2.3.4 Quenching distanc

- Page 141 and 142:

Chapter 4 10000 Quenching distance

- Page 143 and 144:

Chapter 5 CHAPTER 5 EXPERIMENTAL ST

- Page 145 and 146:

Chapter 5 30 10 25 8 Pressure (bar)

- Page 147 and 148:

Chapter 5 30 Piston position (mm) 2

- Page 149 and 150:

Chapter 5 5.1.1.4 In-cylinder press

- Page 151 and 152:

Chapter 5 estimation of various par

- Page 153 and 154:

Chapter 5 TDC 1.25 ms 2.5 ms 3.75 m

- Page 155 and 156:

Chapter 5 Piston position (mm) 500

- Page 157 and 158:

Chapter 5 tel-00623090, version 1 -

- Page 159 and 160:

Chapter 5 From figure 5.15 is possi

- Page 161 and 162:

Chapter 5 From figure 5.16 is obser

- Page 163 and 164:

Chapter 5 80 Pressure (bar) 70 60 5

- Page 165 and 166:

Chapter 5 80 10 Pmax (bar) 70 60 50

- Page 167 and 168:

Chapter 5 -5.0 ms -3.75 ms -2.5 ms

- Page 169 and 170:

Chapter 5 observation emphasis the

- Page 171 and 172:

Chapter 6 CHAPTER 6 NUMERICAL SIMUL

- Page 173 and 174:

Chapter 6 centered at the spark plu

- Page 175 and 176:

Chapter 6 H 2 O, (3) N 2 , (4) O 2

- Page 177 and 178:

Chapter 6 For all the above express

- Page 179 and 180:

Chapter 6 motions within the cylind

- Page 181 and 182:

Chapter 6 tel-00623090, version 1 -

- Page 183 and 184:

Chapter 6 Heat transfer Wei et al.,

- Page 185 and 186:

Chapter 6 The calibration coefficie

- Page 187 and 188:

Chapter 6 6.3.2.2 In-cylinder volum

- Page 189 and 190:

Chapter 6 40 Experimental 30 Numeri

- Page 191 and 192:

Chapter 6 80 70 60 Numerical Experi

- Page 193 and 194:

Chapter 6 downdraft syngas than for

- Page 195 and 196:

Chapter 6 80 23º BTDC 60 29.5º BT

- Page 197 and 198:

Chapter 6 with experimental results

- Page 199 and 200:

Conclusions CHAPTER 7 CONCLUSIONS 7

- Page 201 and 202:

Conclusions radius and time for syn

- Page 203 and 204:

Conclusions conditions, therefore s

- Page 205 and 206:

Conclusions tel-00623090, version 1

- Page 207 and 208:

References References tel-00623090,

- Page 209 and 210:

References tel-00623090, version 1

- Page 211 and 212:

References tel-00623090, version 1

- Page 213 and 214:

References tel-00623090, version 1

- Page 215 and 216:

References tel-00623090, version 1

- Page 217 and 218:

References tel-00623090, version 1

- Page 219 and 220:

References tel-00623090, version 1

- Page 221 and 222:

Appendix A - Overdetermined linear

- Page 223 and 224:

Appendix A - Overdetermined linear

- Page 225 and 226:

Appendix B- Syngas-air mixtures pro

- Page 227 and 228:

Appendix C -Rivère model Heat flux

- Page 229 and 230:

Appendix C -Rivère model The work

- Page 231 and 232:

tel-00623090, version 1 - 13 Sep 20