Linear Way L

Linear Way L

Linear Way L

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

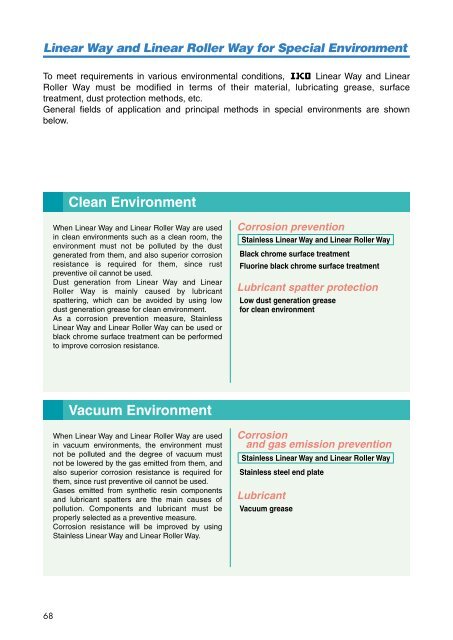

<strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong> for Special Environment<br />

To meet requirements in various environmental conditions, <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong><br />

Roller <strong>Way</strong> must be modified in terms of their material, lubricating grease, surface<br />

treatment, dust protection methods, etc.<br />

General fields of application and principal methods in special environments are shown<br />

below.<br />

Clean Environment<br />

When <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong> are used<br />

in clean environments such as a clean room, the<br />

environment must not be polluted by the dust<br />

generated from them, and also superior corrosion<br />

resistance is required for them, since rust<br />

preventive oil cannot be used.<br />

Dust generation from <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong><br />

Roller <strong>Way</strong> is mainly caused by lubricant<br />

spattering, which can be avoided by using low<br />

dust generation grease for clean environment.<br />

As a corrosion prevention measure, Stainless<br />

<strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong> can be used or<br />

black chrome surface treatment can be performed<br />

to improve corrosion resistance.<br />

Corrosion prevention<br />

Stainless <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong><br />

Black chrome surface treatment<br />

Fluorine black chrome surface treatment<br />

Lubricant spatter protection<br />

Low dust generation grease<br />

for clean environment<br />

Vacuum Environment<br />

When <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong> are used<br />

in vacuum environments, the environment must<br />

not be polluted and the degree of vacuum must<br />

not be lowered by the gas emitted from them, and<br />

also superior corrosion resistance is required for<br />

them, since rust preventive oil cannot be used.<br />

Gases emitted from synthetic resin components<br />

and lubricant spatters are the main causes of<br />

pollution. Components and lubricant must be<br />

properly selected as a preventive measure.<br />

Corrosion resistance will be improved by using<br />

Stainless <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong>.<br />

Corrosion<br />

and gas emission prevention<br />

Stainless <strong>Linear</strong> <strong>Way</strong> and <strong>Linear</strong> Roller <strong>Way</strong><br />

Stainless steel end plate<br />

Lubricant<br />

Vacuum grease<br />

68