Linear Way L

Linear Way L

Linear Way L

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mounting of <strong>Linear</strong> <strong>Way</strong> L<br />

The general mounting structure of <strong>Linear</strong> <strong>Way</strong> L<br />

is similar to that shown in Fig. 5. The slide unit of<br />

this series is mounted by tightening bolts in the<br />

female threads of the slide unit.<br />

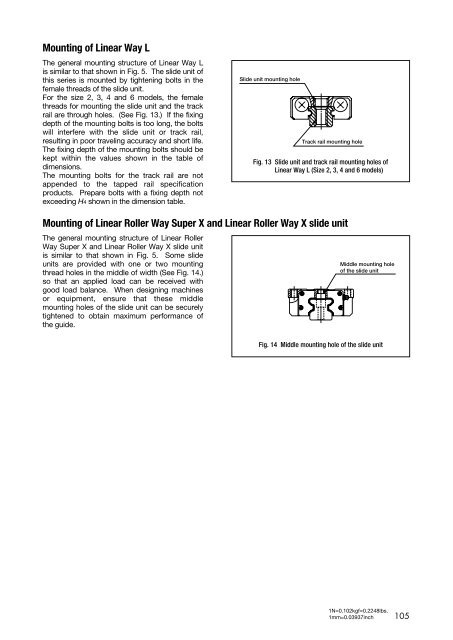

For the size 2, 3, 4 and 6 models, the female<br />

threads for mounting the slide unit and the track<br />

rail are through holes. (See Fig. 13.) If the fixing<br />

depth of the mounting bolts is too long, the bolts<br />

will interfere with the slide unit or track rail,<br />

resulting in poor traveling accuracy and short life.<br />

The fixing depth of the mounting bolts should be<br />

kept within the values shown in the table of<br />

dimensions.<br />

The mounting bolts for the track rail are not<br />

appended to the tapped rail specification<br />

products. Prepare bolts with a fixing depth not<br />

exceeding H4 shown in the dimension table.<br />

Slide unit mounting hole<br />

Track rail mounting hole<br />

Fig. 13 Slide unit and track rail mounting holes of<br />

<strong>Linear</strong> <strong>Way</strong> L (Size 2, 3, 4 and 6 models)<br />

Mounting of <strong>Linear</strong> Roller <strong>Way</strong> Super X and <strong>Linear</strong> Roller <strong>Way</strong> X slide unit<br />

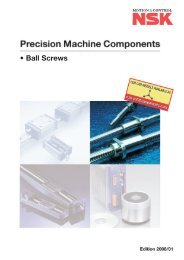

The general mounting structure of <strong>Linear</strong> Roller<br />

<strong>Way</strong> Super X and <strong>Linear</strong> Roller <strong>Way</strong> X slide unit<br />

is similar to that shown in Fig. 5. Some slide<br />

units are provided with one or two mounting<br />

thread holes in the middle of width (See Fig. 14.)<br />

so that an applied load can be received with<br />

good load balance. When designing machines<br />

or equipment, ensure that these middle<br />

mounting holes of the slide unit can be securely<br />

tightened to obtain maximum performance of<br />

the guide.<br />

Middle mounting hole<br />

of the slide unit<br />

Fig. 14 Middle mounting hole of the slide unit<br />

1N=0.102kgf=0.2248lbs.<br />

1mm=0.03937inch<br />

105