Glandless Pumps - THERMO-ECO-ENGINEERING úvod

Glandless Pumps - THERMO-ECO-ENGINEERING úvod

Glandless Pumps - THERMO-ECO-ENGINEERING úvod

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

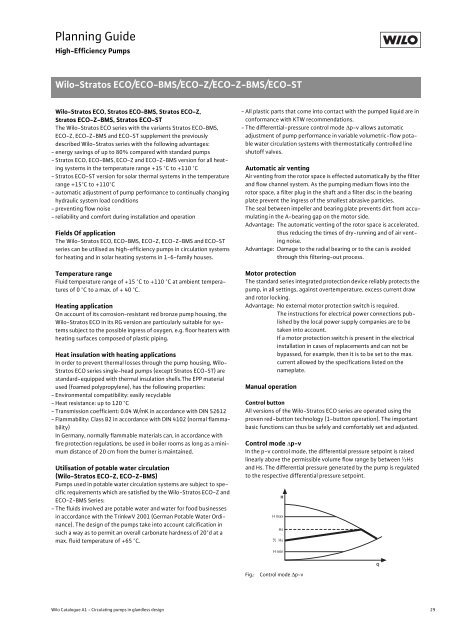

Planning Guide<br />

High-Efficiency <strong>Pumps</strong><br />

Wilo-Stratos <strong>ECO</strong>/<strong>ECO</strong>-BMS/<strong>ECO</strong>-Z/<strong>ECO</strong>-Z-BMS/<strong>ECO</strong>-ST<br />

Wilo-Stratos <strong>ECO</strong>, Stratos <strong>ECO</strong>-BMS, Stratos <strong>ECO</strong>-Z,<br />

Stratos <strong>ECO</strong>-Z-BMS, Stratos <strong>ECO</strong>-ST<br />

The Wilo-Stratos <strong>ECO</strong> series with the variants Stratos <strong>ECO</strong>-BMS,<br />

<strong>ECO</strong>-Z, <strong>ECO</strong>-Z-BMS and <strong>ECO</strong>-ST supplement the previously<br />

described Wilo-Stratos series with the following advantages:<br />

- energy savings of up to 80% compared with standard pumps<br />

- Stratos <strong>ECO</strong>, <strong>ECO</strong>-BMS, <strong>ECO</strong>-Z and <strong>ECO</strong>-Z-BMS version for all heating<br />

systems in the temperature range +15 °C to +110 °C<br />

- Stratos <strong>ECO</strong>-ST version for solar thermal systems in the temperature<br />

range +15°C to +110°C<br />

- automatic adjustment of pump performance to continually changing<br />

hydraulic system load conditions<br />

- preventing flow noise<br />

- reliability and comfort during installation and operation<br />

Fields Of application<br />

The Wilo-Stratos <strong>ECO</strong>, <strong>ECO</strong>-BMS, <strong>ECO</strong>-Z, <strong>ECO</strong>-Z-BMS and <strong>ECO</strong>-ST<br />

series can be utilised as high-efficiency pumps in circulation systems<br />

for heating and in solar heating systems in 1-6-family houses.<br />

Temperature range<br />

Fluid temperature range of +15 °C to +110 °C at ambient temperatures<br />

of 0 °C to a max. of + 40 °C.<br />

Heating application<br />

On account of its corrosion-resistant red bronze pump housing, the<br />

Wilo-Stratos <strong>ECO</strong> in its RG version are particularly suitable for systems<br />

subject to the possible ingress of oxygen, e.g. floor heaters with<br />

heating surfaces composed of plastic piping.<br />

Heat insulation with heating applications<br />

In order to prevent thermal losses through the pump housing, Wilo-<br />

Stratos <strong>ECO</strong> series single-head pumps (except Stratos <strong>ECO</strong>-ST) are<br />

standard-equipped with thermal insulation shells.The EPP material<br />

used (foamed polypropylene), has the following properties:<br />

- Environmental compatibility: easily recyclable<br />

- Heat resistance: up to 120 °C<br />

- Transmission coefficient: 0.04 W/mK in accordance with DIN 52612<br />

- Flammability: Class B2 in accordance with DIN 4102 (normal flammability)<br />

In Germany, normally flammable materials can, in accordance with<br />

fire protection regulations, be used in boiler rooms as long as a minimum<br />

distance of 20 cm from the burner is maintained.<br />

Utilisation of potable water circulation<br />

(Wilo-Stratos <strong>ECO</strong>-Z, <strong>ECO</strong>-Z-BMS)<br />

<strong>Pumps</strong> used in potable water circulation systems are subject to specific<br />

requirements which are satisfied by the Wilo-Stratos <strong>ECO</strong>-Z and<br />

<strong>ECO</strong>-Z-BMS Series:<br />

- The fluids involved are potable water and water for food businesses<br />

in accordance with the TrinkwV 2001 (German Potable Water Ordinance).<br />

The design of the pumps take into account calcification in<br />

such a way as to permit an overall carbonate hardness of 20°d at a<br />

max. fluid temperature of +65 °C.<br />

- All plastic parts that come into contact with the pumped liquid are in<br />

conformance with KTW recommendations.<br />

- The differential-pressure control mode p-v allows automatic<br />

adjustment of pump performance in variable volumetric-flow potable<br />

water circulation systems with thermostatically controlled line<br />

shutoff valves.<br />

Automatic air venting<br />

Air venting from the rotor space is effected automatically by the filter<br />

and flow channel system. As the pumping medium flows into the<br />

rotor space, a filter plug in the shaft and a filter disc in the bearing<br />

plate prevent the ingress of the smallest abrasive particles.<br />

The seal between impeller and bearing plate prevents dirt from accumulating<br />

in the A-bearing gap on the motor side.<br />

Advantage: The automatic venting of the rotor space is accelerated,<br />

thus reducing the times of dry-running and of air venting<br />

noise.<br />

Advantage: Damage to the radial bearing or to the can is avoided<br />

through this filtering-out process.<br />

Motor protection<br />

The standard series integrated protection device reliably protects the<br />

pump, in all settings, against overtemperature, excess current draw<br />

and rotor locking.<br />

Advantage: No external motor protection switch is required.<br />

The instructions for electrical power connections published<br />

by the local power supply companies are to be<br />

taken into account.<br />

If a motor protection switch is present in the electrical<br />

installation in cases of replacements and can not be<br />

bypassed, for example, then it is to be set to the max.<br />

current allowed by the specifications listed on the<br />

nameplate.<br />

Manual operation<br />

Control button<br />

All versions of the Wilo-Stratos <strong>ECO</strong> series are operated using the<br />

proven red-button technology (1-button operation). The important<br />

basic functions can thus be safely and comfortably set and adjusted.<br />

Control mode p-v<br />

In the p-v control mode, the differential pressure setpoint is raised<br />

linearly above the permissible volume flow range by between ½Hs<br />

and Hs. The differential pressure generated by the pump is regulated<br />

to the respective differential pressure setpoint.<br />

Fig.:<br />

H max<br />

1 /2<br />

H<br />

Hs<br />

Hs<br />

H min<br />

Control mode p-v<br />

Q<br />

Heating, Air-conditioning,<br />

Cooling<br />

Potable water circulation<br />

Solar thermal<br />

Service/Accessories, Systems<br />

Switchgears and Control<br />

Devices Pump Management<br />

Systems<br />

Wilo Catalogue A1 - Circulating pumps in glandless design<br />

29