Technical Specifications - UNDP

Technical Specifications - UNDP

Technical Specifications - UNDP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

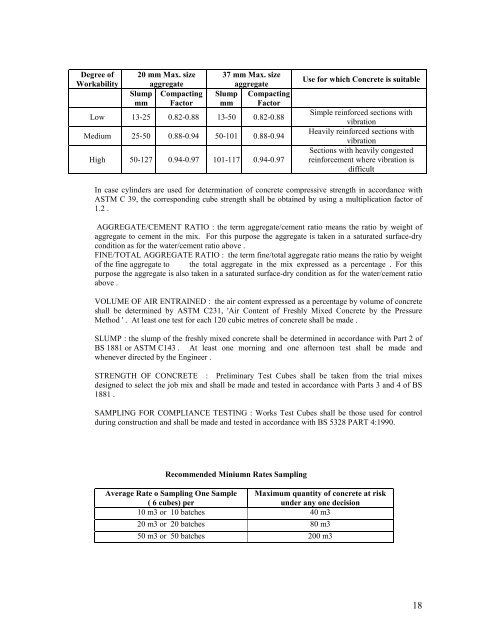

Degree of<br />

Workability<br />

20 mm Max. size<br />

aggregate<br />

Slump Compacting<br />

mm Factor<br />

37 mm Max. size<br />

aggregate<br />

Slump Compacting<br />

mm Factor<br />

Low 13-25 0.82-0.88 13-50 0.82-0.88<br />

Medium 25-50 0.88-0.94 50-101 0.88-0.94<br />

High 50-127 0.94-0.97 101-117 0.94-0.97<br />

Use for which Concrete is suitable<br />

Simple reinforced sections with<br />

vibration<br />

Heavily reinforced sections with<br />

vibration<br />

Sections with heavily congested<br />

reinforcement where vibration is<br />

difficult<br />

In case cylinders are used for determination of concrete compressive strength in accordance with<br />

ASTM C 39, the corresponding cube strength shall be obtained by using a multiplication factor of<br />

1.2 .<br />

AGGREGATE/CEMENT RATIO : the term aggregate/cement ratio means the ratio by weight of<br />

aggregate to cement in the mix. For this purpose the aggregate is taken in a saturated surface-dry<br />

condition as for the water/cement ratio above .<br />

FINE/TOTAL AGGREGATE RATIO : the term fine/total aggregate ratio means the ratio by weight<br />

of the fine aggregate to the total aggregate in the mix expressed as a percentage . For this<br />

purpose the aggregate is also taken in a saturated surface-dry condition as for the water/cement ratio<br />

above .<br />

VOLUME OF AIR ENTRAINED : the air content expressed as a percentage by volume of concrete<br />

shall be determined by ASTM C231, 'Air Content of Freshly Mixed Concrete by the Pressure<br />

Method ' . At least one test for each 120 cubic metres of concrete shall be made .<br />

SLUMP : the slump of the freshly mixed concrete shall be determined in accordance with Part 2 of<br />

BS 1881 or ASTM C143 . At least one morning and one afternoon test shall be made and<br />

whenever directed by the Engineer .<br />

STRENGTH OF CONCRETE : Preliminary Test Cubes shall be taken from the trial mixes<br />

designed to select the job mix and shall be made and tested in accordance with Parts 3 and 4 of BS<br />

1881 .<br />

SAMPLING FOR COMPLIANCE TESTING : Works Test Cubes shall be those used for control<br />

during construction and shall be made and tested in accordance with BS 5328 PART 4:1990.<br />

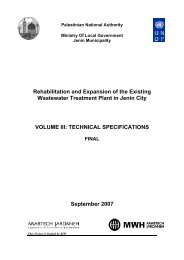

Recommended Miniumn Rates Sampling<br />

Average Rate o Sampling One Sample Maximum quantity of concrete at risk<br />

( 6 cubes) per<br />

under any one decision<br />

10 m3 or 10 batches 40 m3<br />

20 m3 or 20 batches 80 m3<br />

50 m3 or 50 batches 200 m3<br />

18