CMDITR Review of Undergraduate Research - Pluto - University of ...

CMDITR Review of Undergraduate Research - Pluto - University of ...

CMDITR Review of Undergraduate Research - Pluto - University of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Two-Photon Induced Free Radical Polymerization<br />

Mitchell J. Witkowski, <strong>University</strong> <strong>of</strong> Washington<br />

Jen Lab, Dept. <strong>of</strong> Materials Science & Engineering, <strong>University</strong> <strong>of</strong> Washington<br />

Introduction<br />

Two-photon absorption is a statistically rare,<br />

nonlinear optical event. The probability for a<br />

molecule to absorb two photons goes as the<br />

square <strong>of</strong> the intensity <strong>of</strong> the incident light. By<br />

using a femtosecond mode-locked laser, focused<br />

into a small volume, enough photons are present<br />

for the event to occur in a reasonable amount <strong>of</strong><br />

time. A specially designed chromophore, with a<br />

high two-photon cross section, absorbs these two<br />

photons and is induced to fluoresce a single,<br />

high-energy photon. Note that these single<br />

photons are produced from within a volume<br />

smaller than the diffraction limit <strong>of</strong> the laser due<br />

to the quadratic dependence <strong>of</strong> two-photon<br />

absorption. This single photon then causes<br />

photo-polymerization <strong>of</strong> the resin by generating<br />

free radicals. 1-6<br />

Objective<br />

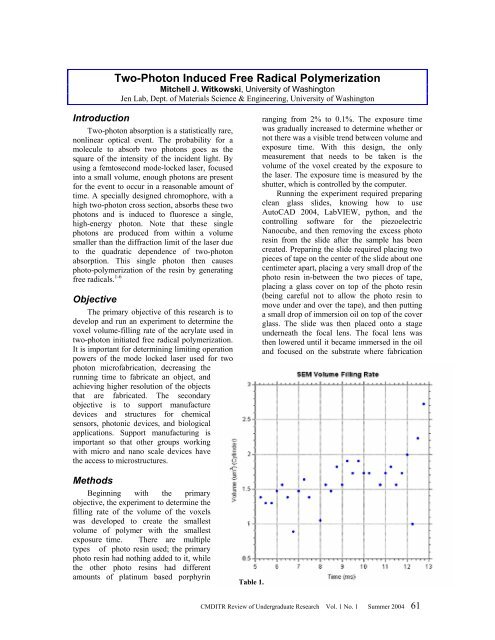

The primary objective <strong>of</strong> this research is to<br />

develop and run an experiment to determine the<br />

voxel volume-filling rate <strong>of</strong> the acrylate used in<br />

two-photon initiated free radical polymerization.<br />

It is important for determining limiting operation<br />

powers <strong>of</strong> the mode locked laser used for two<br />

photon micr<strong>of</strong>abrication, decreasing the<br />

running time to fabricate an object, and<br />

achieving higher resolution <strong>of</strong> the objects<br />

that are fabricated. The secondary<br />

objective is to support manufacture<br />

devices and structures for chemical<br />

sensors, photonic devices, and biological<br />

applications. Support manufacturing is<br />

important so that other groups working<br />

with micro and nano scale devices have<br />

the access to microstructures.<br />

Methods<br />

Beginning with the primary<br />

objective, the experiment to determine the<br />

filling rate <strong>of</strong> the volume <strong>of</strong> the voxels<br />

was developed to create the smallest<br />

volume <strong>of</strong> polymer with the smallest<br />

exposure time. There are multiple<br />

types <strong>of</strong> photo resin used; the primary<br />

photo resin had nothing added to it, while<br />

the other photo resins had different<br />

amounts <strong>of</strong> platinum based porphyrin<br />

Table 1.<br />

ranging from 2% to 0.1%. The exposure time<br />

was gradually increased to determine whether or<br />

not there was a visible trend between volume and<br />

exposure time. With this design, the only<br />

measurement that needs to be taken is the<br />

volume <strong>of</strong> the voxel created by the exposure to<br />

the laser. The exposure time is measured by the<br />

shutter, which is controlled by the computer.<br />

Running the experiment required preparing<br />

clean glass slides, knowing how to use<br />

AutoCAD 2004, LabVIEW, python, and the<br />

controlling s<strong>of</strong>tware for the piezoelectric<br />

Nanocube, and then removing the excess photo<br />

resin from the slide after the sample has been<br />

created. Preparing the slide required placing two<br />

pieces <strong>of</strong> tape on the center <strong>of</strong> the slide about one<br />

centimeter apart, placing a very small drop <strong>of</strong> the<br />

photo resin in-between the two pieces <strong>of</strong> tape,<br />

placing a glass cover on top <strong>of</strong> the photo resin<br />

(being careful not to allow the photo resin to<br />

move under and over the tape), and then putting<br />

a small drop <strong>of</strong> immersion oil on top <strong>of</strong> the cover<br />

glass. The slide was then placed onto a stage<br />

underneath the focal lens. The focal lens was<br />

then lowered until it became immersed in the oil<br />

and focused on the substrate where fabrication<br />

<strong>CMDITR</strong> <strong>Review</strong> <strong>of</strong> <strong>Undergraduate</strong> <strong>Research</strong> Vol. 1 No. 1 Summer 2004 61