CMDITR Review of Undergraduate Research - Pluto - University of ...

CMDITR Review of Undergraduate Research - Pluto - University of ...

CMDITR Review of Undergraduate Research - Pluto - University of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

heated bath. The glass test tube holding the<br />

monomer is slowly lowered into the heated bath<br />

at a constant speed ranging from 10 to 15<br />

microns per second depending on whether or not<br />

there was any dopant, and what kind <strong>of</strong> dopant.<br />

This was setup so the preform would be lowered<br />

down into the bath gradually, allowing enough<br />

time for the submerged monomer to polymerize<br />

at a constant rate.<br />

The fiber-drawing tower has a motor that<br />

can be set to move at very slow speeds, and this<br />

was used to lower the preform into the bath. The<br />

preform was lowered into the bath by tying it<br />

with string to a metal rod fixed to a platform<br />

already used for lowering preforms into the<br />

furnace. This was advantageous because<br />

LabView computer s<strong>of</strong>tware controls the speedsensitive<br />

motor. For a set speed, the motor will<br />

continuously lower the preform into the bath.<br />

The setup for temperature monitoring was<br />

already in place in the draw tower, with an<br />

electronic reader available. A type K<br />

thermocouple was placed in the middle <strong>of</strong> the oil<br />

bath to monitor the temperature. Experimentally<br />

it was determined that polymerization occurs<br />

best at approximately 80°C. The speed at which<br />

the preform was lowered into the bath is variable<br />

depending on whether or not the monomer was<br />

doped, and if so, the type <strong>of</strong> dopant.<br />

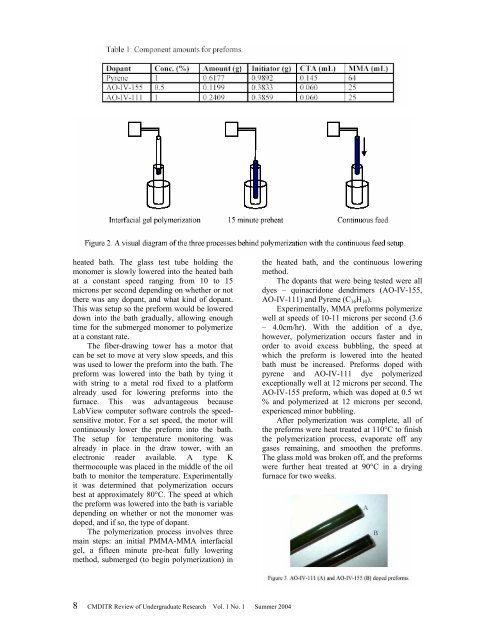

The polymerization process involves three<br />

main steps: an initial PMMA-MMA interfacial<br />

gel, a fifteen minute pre-heat fully lowering<br />

method, submerged (to begin polymerization) in<br />

the heated bath, and the continuous lowering<br />

method.<br />

The dopants that were being tested were all<br />

dyes – quinacridone dendrimers (AO-IV-155,<br />

AO-IV-111) and Pyrene (C 16 H 10 ).<br />

Experimentally, MMA preforms polymerize<br />

well at speeds <strong>of</strong> 10-11 microns per second (3.6<br />

– 4.0cm/hr). With the addition <strong>of</strong> a dye,<br />

however, polymerization occurs faster and in<br />

order to avoid excess bubbling, the speed at<br />

which the preform is lowered into the heated<br />

bath must be increased. Preforms doped with<br />

pyrene and AO-IV-111 dye polymerized<br />

exceptionally well at 12 microns per second. The<br />

AO-IV-155 preform, which was doped at 0.5 wt<br />

% and polymerized at 12 microns per second,<br />

experienced minor bubbling.<br />

After polymerization was complete, all <strong>of</strong><br />

the preforms were heat treated at 110°C to finish<br />

the polymerization process, evaporate <strong>of</strong>f any<br />

gases remaining, and smoothen the preforms.<br />

The glass mold was broken <strong>of</strong>f, and the preforms<br />

were further heat treated at 90°C in a drying<br />

furnace for two weeks.<br />

8 <strong>CMDITR</strong> <strong>Review</strong> <strong>of</strong> <strong>Undergraduate</strong> <strong>Research</strong> Vol. 1 No. 1 Summer 2004