W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

COVER AND<br />

FILTER ELEMENT<br />

OIL LEVEL<br />

BREATHER<br />

VALVE<br />

(TH. THD)<br />

Fig.6<br />

Clean bowl regularly of accumulate dust and dirt. Do not use<br />

oil or water in pre-cleaner, this must be kept dry.<br />

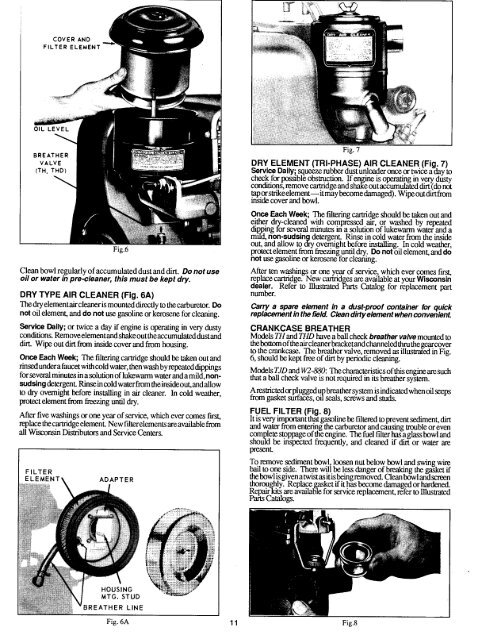

DRY TYPE AIR CLEANER (Fig. 6A)<br />

<strong>Th</strong>e dry elementair cleaner is mountedirecdy to the cafouretor. Do<br />

not oil element, and do not use gasoline or kerosene for cleaning.<br />

Service Daily; or twice a day if engine is operating in very dusty<br />

conditions. Remove elementand shake outthe accumulawxl dust and<br />

dirt. Wipe out dirt from inside cover and from housing.<br />

Once Each Week; <strong>Th</strong>e filtering cartridge should be taken out and<br />

rinsed under a faucet with cold water, then wash by repeated dipping s<br />

for several minutes in a solution of lukewarm water and a mild, nonsudsing<br />

detergent. Rinse in cold water from the inside out, and allow<br />

to dry overnight before installing in air cleaner. In cold weather,<br />

protect element from freezing until dry.<br />

After five washings or one year of service, which ever comes first,<br />

replace the cartridge element. New filter elements are available from<br />

all <strong>Wisconsin</strong> Distributors and Service Centers.<br />

FILTER<br />

ELEMENT’<br />

ADAPTER<br />

Fig. 7<br />

DRY ELEMENT (TRI-PHASE) AIR CLEANER (Fig. 7)<br />

Service Daily; squeeze rubber dust unloader once or twice a day to<br />

check for possible obstruction. If engine is operating in very dusty<br />

conditio.n.s, remove cartridge and shake out accumulated dirt (do not<br />

~ap or strikeelement--it may become damaged). Wipeoutdirtfrom<br />

inside cover and bowl.<br />

Once Each Week; <strong>Th</strong>e filtering cartridge should be taken out and<br />

either dry-cleaned with compressed air, or washed by repeated<br />

dipping for several minutes hi a solution of lukewarm water and a<br />

mild, non-sudsing detergent. Rinse in cold water from the inside<br />

out, and.allow to dry ovei’night before installing. In cold weather,<br />

protect element from freezing until dry. Do not oil element, and do<br />

not use gasoline or kerosene for cleaning.<br />

After ten washings or one year of service, which ever comes first,<br />

replace cartridge. New cariridges are available at your <strong>Wisconsin</strong><br />

dealer. Refer to glustmted Pans Catalog for replacement part<br />

number.<br />

Carry a spare element in a dust-proof container for quick<br />

replacement in the t’mid. Clean dirty element when convenient.<br />

CRANKCASE BREATHER<br />

Models TH and THD have a ball check breather valve mounted to<br />

the bollom of the air cleaner bracket and channeled thru the gear cover<br />

to the crankcase. <strong>Th</strong>e breather valve, removed as illustrated in Fig.<br />

6, should be kept free of dirt by periodic cleaning.<br />

Models TJD and <strong>W2</strong>-<strong>880</strong>: <strong>Th</strong>e characteristics of this engine are such<br />

that a ball check valve is not required in its breather system.<br />

A reslricted or plugged up breather system is indicated when oil seeps<br />

from gasket stirfa-c~s, oflseals, screws and studs.<br />

FUEL FILTER (Fig. 8)<br />

It is.. very in~.portant that gasoline be faltered to prevent sediment, dirt<br />

ana w.ater from entering the carburetor and causing lrouble or even<br />

complete stoppage of the engine. <strong>Th</strong>e fuel fdter ha~ a glass bowl and<br />

should be inspected frequently, and cleaned if dirt or water are<br />

present.<br />

To.remove sediment bowl, loosen nut below bowl and swing wire<br />

bail to one side. <strong>Th</strong>ere will be less danger of breaking the gasket if<br />

the bowl is given a twist as it is being removed. Clean bowl and screen<br />

thoroughly. Replace gasket if it has become damaged or hardened.<br />

_<strong>Repair</strong>kits are available for service replacement, refer to Illuslrated<br />

varts Catalogs.<br />

HOUSING<br />

MTG. STUD<br />

~REATHER LINE<br />

Fig. 6A 11 Fig.8