W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fig. 33<br />

to the gear cover and the six screws to the cylinder<br />

shrouding must be removed to disassemble flywheel<br />

shroud from engine.<br />

SIDE MOUNT FUEL TANK<br />

If it is necessary the side mount fuel tank and bracket<br />

be disassembled, loosen the tank strap screws and<br />

remove the tank. <strong>Th</strong>is will make the four screws for<br />

mounting the tank bracket to the crankcase and engine<br />

base accessible. Otherwise, just remove the two<br />

screws holding the bracket to the crankcase and remove<br />

the tank and bracket assembly along with the<br />

engine base when it is removed.<br />

CARBURETOR AND MANIFOLD (Fig. 34)<br />

Remove the cotter pin from the governor control rod<br />

and pull the rod from the control lever. Take out the<br />

two capscrews which hold the air cleaner connection<br />

bracket to the gear cover and remove the two nuts and<br />

square washers from the manifold studs. <strong>Th</strong>e complete<br />

carburetor, manifold and air cleaner connection<br />

bracket can be removed as a complete unit.<br />

In reassembly; tighten the nuts for mounting the manifold<br />

to 26 foot pounds torque. Tightening beyond<br />

specification may cause the square washers to crack.<br />

Fig. 34<br />

In reassembly; all carbon and lead deposits should be<br />

removed. It is recommended that a new cylinder head<br />

gasket be used as the old gasket will be compressed<br />

and hard. Apply a mixture of graphite and oil on the<br />

cylinder head screws to prevent them from rusting<br />

tight against the cylinder block. Tighten cylinder<br />

head screws 22 to 24 foot pounds torque. After complete<br />

assembly and engine is run in, retorque.<br />

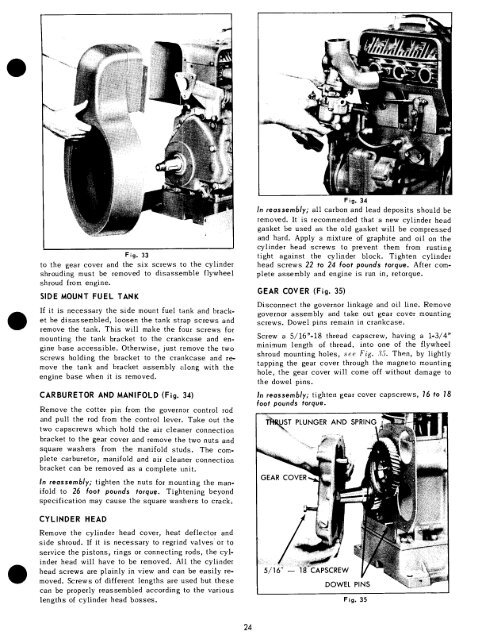

GEAR COVER (Fig. 35)<br />

Disconnect the governor linkage and oil line. Remove<br />

governor assembly and take out gear cover mounting<br />

screws. Dowel pins remain in crankcase.<br />

Screw a 5/16"-18 thread capscrew, having a 1o3/4"<br />

minimum length of thread, into one of the flywheel<br />

shroud mounting holes, see Fig. 35. <strong>Th</strong>en, by lightly<br />

tapping the gear cover through the magneto mounting<br />

hole, the gear cover will come off without damage to<br />

the dowel pins.<br />

In reassembly; tighten gear cover capscrews, 16 to 18<br />

foot pounds torque.<br />

J T~T PLUNGER AND SPRING<br />

CYLINDER HEAD<br />

Remove the cylinder head cover, heat deflector and<br />

side shroud. If it is necessary to regrind valves’ or to<br />

service the pistons, rings or connecting rods, the cylinder<br />

head will have to be removed. All the cylinder<br />

head screws are plainly in view and can be easily removed.<br />

Screws of different lengths are used but these<br />

can be properly reassembled according to the various<br />

lengths of cylinder head bosses.<br />

5/16" -- CAPSCREW<br />

DOWEL PINS<br />

Fig. 35<br />

24