W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

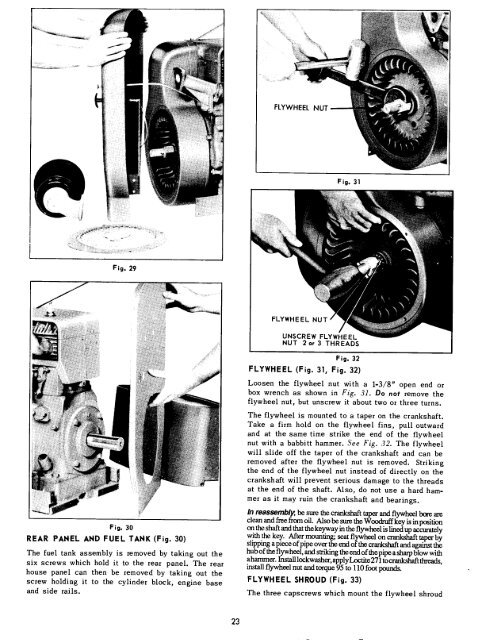

FLYWHEEL NUT<br />

Fig. 31<br />

Fig. 29<br />

FLYWHEEL NUT<br />

UNSCREW FLYWHEEL<br />

NUT 2or 3 THREADS<br />

Fig. 30<br />

REAR PANEL AND FUEL TANK (Fig. 30)<br />

<strong>Th</strong>e fuel tank assembly is removed by taking out the<br />

six screws which hold it to the rear panel. <strong>Th</strong>e rear<br />

house panel can then be removed by taking out the<br />

screw holding it to the cylinder block, engine base<br />

and side rails.<br />

Fig. 32<br />

FLYWHEEL (Fig. 31, Fig. 32)<br />

Loosen the flywheel nut with a 1-3/8" open end or<br />

box wrench as shown in Fig. 31. Do not remove the<br />

flywheel nut, but unscrew it about two or three turns.<br />

<strong>Th</strong>e flywheel is mounted to a taper on the crankshaft.<br />

Take a firm hold on the flywheel fins, pull outward<br />

and at the same time strike the end of the flywheel<br />

nut with a babbitt hammer. See Fig. 32. <strong>Th</strong>e flywheel<br />

will slide off the taper of the crankshaft and can be<br />

removed after the flywheel nut is removed. Striking<br />

the end of the flywheel nut instead of directly on the<br />

crankshaft will prevent serious damage to the threads<br />

at the end of the shaft. Also, do not use a hard hammer<br />

as it may ruin the crankshaft and bearings.<br />

In reassemble be sum the crankshaft Japer and flywheel bore arc<br />

clean and free from oil. Also be sure the Woodruffkey is in position<br />

on the shaft and that the keyway in the flywheel is lined up accurately<br />

with the key. After mounting; seat flywheel on crankshaft taper by<br />

slipping a piece of pipe over the end of the crankshaft and against the<br />

hub of the flywheel, and striking the end of the pipe a sharp blow with<br />

a hammer. Install lockwasher, applyLoctite 271 tocrankshaft threads,<br />

install flywheel nut and torque 95 to 110 foot pounds.<br />

FLYWHEEL SHROUD (Fig. 33)<br />

<strong>Th</strong>e three capscrews which mount the flywheel<br />

shroud<br />

23