W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Y-80 Series<br />

MAGNETO SERVICE INSTRUCTIONS<br />

(TYPE FM-X1-2B7-1)<br />

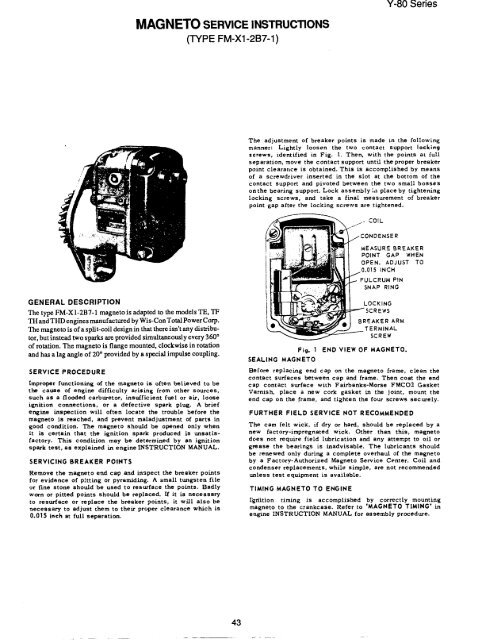

<strong>Th</strong>e adjustment of breaker points is made in the following<br />

manner: Lightly loosen the two contact support locking<br />

screws, identified in Fig. 1. <strong>Th</strong>en. with the points at full<br />

separation, move the contact support until the proper breaker<br />

point clearance is obtained. <strong>Th</strong>is is accomplished by means<br />

of a screwdriver inserted in the slot at the bottom of the<br />

contact support and pivoted between the two small bosses<br />

onthe bearing support. Lock assembly ’~,a place by tightening<br />

locking screws, and take a final measurement of breaker<br />

point gap after the locking screws are tightened.<br />

//j-<br />

COIL<br />

../CONDENSER<br />

MEASURE BREAKER<br />

POINT GAP WHEN<br />

OPEN. ADJUST TO<br />

j0.0’( 5 INCH<br />

~. FULCRUM PIN<br />

SNAP RING<br />

GENERAL DESCRIPTION<br />

<strong>Th</strong>e type FM-XI-2B7-1 magneto is adapted to the models TE, TF<br />

TH and THD engines manufactured by Wis-Con Total Power Corp.<br />

<strong>Th</strong>e magneto is of a split-coil design in that there isn’t any distributor,<br />

°<br />

but instead two sparks are provided simultaneously every 360<br />

of rotation. <strong>Th</strong>e magneto is flange mounted, clockwise in rotation<br />

and has a lag angle of 20 ° provided by a special impulse coupling.<br />

SERVICE<br />

PROCEDURE<br />

Improper functioning of the magneto is often believed to be<br />

the cause of engine difficulty arising from other sources,<br />

such as a flooded carburetor, insufficient fuel or air, loose<br />

ignition connections, or a defective spark plug. A brief<br />

engine inspection will often locate the trouble before the<br />

magneto is reached, and prevent maladjustment of parts in<br />

good condition. <strong>Th</strong>e magneto should be opened only when<br />

it is certain that the ignition spark produced is unsatisfactory.<br />

<strong>Th</strong>is condition may be determined by an ignition<br />

spark test, as explained in engine INSTRUCTION MANUAL.<br />

SERVICING BREAKER POINTS<br />

Remove the magneto end cap and inspect the breaker points<br />

for evidence of pitting or pyramiding. A small tungsten file<br />

or fine stone should be used to resurface the points. Badly<br />

worn or pitted points should be replaced. If it is necessary<br />

to restlrface or replace the breaker points, it will also be<br />

necessary to adjust them to their proper clearance which is<br />

0.015 inch at full separation,<br />

SEALING<br />

LOCKING<br />

==’"’SCREWS<br />

BREAKER ARM<br />

___.__TERMINAL<br />

SCREW<br />

Fig. I END VIEW OF MAGNETO.<br />

MAGNETO<br />

Before replacing end cap on the magneto frame, clean the<br />

contact surfaces between cap and frame. <strong>Th</strong>en coat the end<br />

cap contact surface with Fairbanks-Morse FMCO2 Gasket<br />

Varnish, place a new cork gasket in the joint, mount the<br />

end cap on the frame, and tighten the four screws securely.<br />

FURTHER FIELD SERVICE NOT RECOMMENDED<br />

<strong>Th</strong>e cam felt wick, if dry or hard, should be replaced by a<br />

new factory-impregnated wick. Other than this, magneto<br />

does not require field lubrication and any attempt to oil or<br />

grease the bearings is inadvisable. <strong>Th</strong>e lubricants should<br />

be renewed only during a comptete overhaul of the magneto<br />

by a Factory-Authorized Magneto Service Center. Coil and<br />

condenser replacements, while simple, are not recommended<br />

unless test equipment is avaitable.<br />

TIMING<br />

MAGNETO TO ENGINE<br />

I~dition timing is accomplished by correctly mounting<br />

magneto to the crankcase. Refer to ’MAGNETO TIMING’ in<br />

engine INSTRUCTION MANUAL for assembly procedure.<br />

43