W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

W2-880 Tjd, Thd, Th - Repair - Wisconsin Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CARBURETOR ADJUSTMENT<br />

<strong>Th</strong>e main metering jet in the carburetor is ot the fixed<br />

type and therefore no adjustment is necessary.<br />

<strong>Th</strong>e correct amount of throttle plate opening for the<br />

proper low idle speed is obtained by means of the<br />

tbrcttle stop screw. However, this is set at the factory<br />

so that no immediate adjustment is necessary. <strong>Th</strong>e<br />

idle adjustment is for smooth low speed .operation and<br />

this adjustment, if necessary, must be made with the<br />

carburetor throttle lever dosed.<br />

For further information, refer to Carburetor Service Instructions in<br />

this manual.<br />

MAGNETO IGNITION<br />

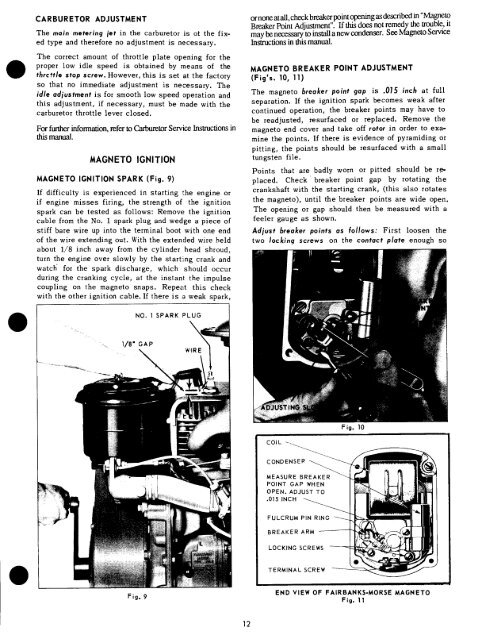

MAGNETO IGNITION SPARK (Fig. 9)<br />

If difficulty is experienced in starting ~,he engine or<br />

if engine misses firing, the strength of the ignition<br />

spark can be tested as follows: Remove the ignition<br />

cable from the No. 1 spark plug and wedge a piece of<br />

stiff bare wire up into the terminal boot with one end<br />

of the wire extending out. With the extended wire held<br />

about 1/8 inch away from the cylinder head shroud,<br />

turn the engine over slowly by the start!ing crank and<br />

watch for the spark discharge, which should occur<br />

during the cranking cycle, at the instant the impulse<br />

coupling on the magneto snaps. Repeat this check<br />

with the other ignition cable. If there is a weak spark,<br />

or none at all, check breaker point opening as described in "Magneto<br />

Breaker Point Adjustment". If this does not remedy the trouble, it<br />

may be necessary to install a new condenser. See Magneto Service<br />

Instructions in this manual.<br />

MAGNETO BREAKER POINT ADJUSTMENT<br />

(Fig’s. 10, 11)<br />

<strong>Th</strong>e magneto breaker point gap is .015 inch at full<br />

separation. If the ignition spark becomes weak after<br />

continued operation, the breaker points may have to<br />

be readjusted, resurfaced or replaced. Remove the<br />

magneto end cover and take off rotor in order to examine<br />

the points. If there is evidence of pyramiding or<br />

pitting, the points should be resurfaced with a small<br />

tungsten file.<br />

Points that are badly worn or pitted should be replaced.<br />

Checkbreaker point gap by rotating the<br />

crankshaft with the starting crank, (this also rotates<br />

the magneto), until the breaker points are wide open.<br />

<strong>Th</strong>e opening or gap should then be measured with a<br />

feeler gauge as shown.<br />

Adjust breaker points as follows: First loosen the<br />

two Iockin¢l screws on the contact plate enough so<br />

NO. I SPARK I:LUG<br />

I/8"<br />

GAP<br />

Fig. 10<br />

COIL<br />

CONDENSER<br />

MEASURE BREAKER<br />

POINT GAP WHEN<br />

OPEN. ADJUST TO<br />

.015 INCH<br />

FULCRUM PIN RING<br />

BREAKER ARM<br />

LOCKING SCREWS<br />

TERMINAL SCREW<br />

Fig. 9<br />

END VIEW OF FAIRBANKS-MORSE MAGNETO<br />

Fig. I1<br />

12