MOTOX Gearbox for monorail conveyors - DS TECH

MOTOX Gearbox for monorail conveyors - DS TECH

MOTOX Gearbox for monorail conveyors - DS TECH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

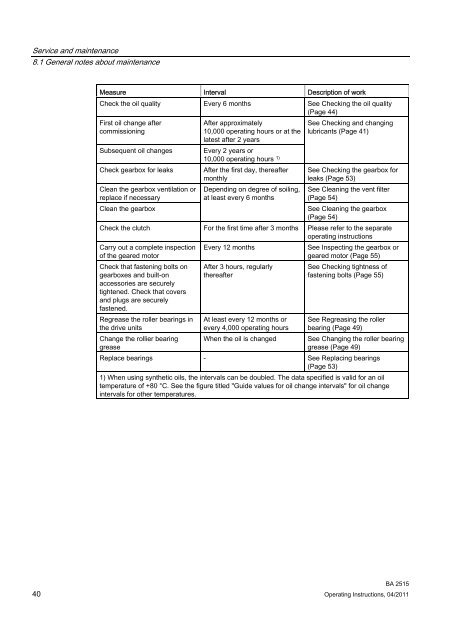

Service and maintenance<br />

8.1 General notes about maintenance<br />

Measure Interval Description of work<br />

Check the oil quality Every 6 months See Checking the oil quality<br />

(Page 44)<br />

First oil change after<br />

commissioning<br />

Subsequent oil changes<br />

Check gearbox <strong>for</strong> leaks<br />

Clean the gearbox ventilation or<br />

replace if necessary<br />

Clean the gearbox<br />

After approximately<br />

10,000 operating hours or at the<br />

latest after 2 years<br />

Every 2 years or<br />

10,000 operating hours 1)<br />

After the first day, thereafter<br />

monthly<br />

Depending on degree of soiling,<br />

at least every 6 months<br />

See Checking and changing<br />

lubricants (Page 41)<br />

See Checking the gearbox <strong>for</strong><br />

leaks (Page 53)<br />

See Cleaning the vent filter<br />

(Page 54)<br />

See Cleaning the gearbox<br />

(Page 54)<br />

Check the clutch For the first time after 3 months Please refer to the separate<br />

operating instructions<br />

Carry out a complete inspection<br />

of the geared motor<br />

Check that fastening bolts on<br />

gearboxes and built-on<br />

accessories are securely<br />

tightened. Check that covers<br />

and plugs are securely<br />

fastened.<br />

Regrease the roller bearings in<br />

the drive units<br />

Change the rollier bearing<br />

grease<br />

Every 12 months<br />

After 3 hours, regularly<br />

thereafter<br />

At least every 12 months or<br />

every 4,000 operating hours<br />

When the oil is changed<br />

See Inspecting the gearbox or<br />

geared motor (Page 55)<br />

See Checking tightness of<br />

fastening bolts (Page 55)<br />

See Regreasing the roller<br />

bearing (Page 49)<br />

See Changing the roller bearing<br />

grease (Page 49)<br />

Replace bearings - See Replacing bearings<br />

(Page 53)<br />

1) When using synthetic oils, the intervals can be doubled. The data specified is valid <strong>for</strong> an oil<br />

temperature of +80 °C. See the figure titled "Guide values <strong>for</strong> oil change intervals" <strong>for</strong> oil change<br />

intervals <strong>for</strong> other temperatures.<br />

BA 2515<br />

40 Operating Instructions, 04/2011