LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Simplicity ® Plane Bearings<br />

Design Notes - Polymer Series<br />

Linear Motion Systems<br />

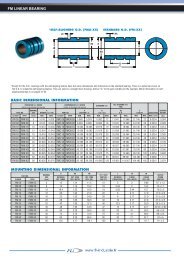

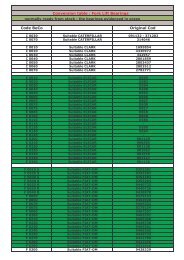

TOLERANCE<br />

Polymer plane bearings are suitible as press-in bu shing,<br />

preferably used in housings with tolerance H7. The press fit<br />

oversize depends on the nominal diameter and the respective<br />

material. The press fit oversize is about 0.5 - 1.5% according<br />

to the chosen diameter.<br />

After assembly in the inside diameter adjusts itself to the<br />

nominal value. A certain clearance in the bearing is necessary<br />

to guarantee faultless operation under all operational<br />

conditions. Inside diameter lies in the ran ge of tolerance F10<br />

according to compound.<br />

Shafts are mainly in tolerance h9 - h7. The ideal sliding<br />

counterpart is steel with a ground surface (surface roughness<br />

value with parameter Ra 0.4 to 0.8 m) and a minumum<br />

hardness of 50 HRC. Apart from hardened steel nearly all<br />

other common shaft materials can be used: stainless steel,<br />

carbon steel, non-ferrous metals and plastics. Special<br />

compounds are available for soft shafts made for example<br />

out of non-ferrous metals or alumi num alloys. Thus, we can<br />

achieve very low to no wear in the sliding counterpart.<br />

For special applications please contact us. We are able<br />

to formulate service life on the basis of our tests for and<br />

experience from a huge number of applications.<br />

MACHINING<br />

Polymer plane bearings can be reworked without problem.<br />

Milling, turning on a lathe, sawing or cutting can be done,<br />

however, please do not alter I.D.<br />

LUBRICATION<br />

Compound plane bearings are self-lubricating and therefor<br />

maintenance-free. Nevertheless, initial lubrication during<br />

assembly or cooling by environmental media can multiply<br />

loading capacity and service life. The compounds are resistant<br />

against most of the common greases and oils. Detailed<br />

information can be obtained from the chemicals resistance list in<br />

this catalog or you can receive a detailed list on request.<br />

ASSEMBLY<br />

It is preferable to press polymer plane bearings into the<br />

housing with an arbor parallel to the axis. The one-sided<br />

chamfer on the bearing simplifies assembly. A similar chamfer<br />

should also be part of the housing.<br />

Design Notes<br />

Dhousing+2a<br />

FD+1<br />

ID-0.2<br />

ID-0.2<br />

WIDTH OF CHAMFER<br />

L-1<br />

L-1<br />

ROUNDED EDGE<br />

ROUNDED EDGE<br />

FD<br />

ID<br />

L<br />

ID<br />

L<br />

a<br />

45°<br />

OD<br />

45°<br />

OD<br />

a<br />

D housing<br />

D housing<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

800.962.8979 • www.pacific-bearing.com 115