LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

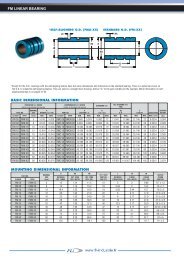

Redi-Rail ® Steel Linear Guides<br />

Technical Information<br />

Linear Motion Systems<br />

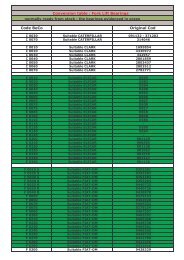

SYSTEM LIFE<br />

Fc = coefficient depending on the actual length of the stroke.<br />

This is an important factor in the case of applications with short<br />

stroke and high frequency. In these cases total lifetime in km is<br />

much shorter, than if application with long strokes. The factor<br />

is equal to 1 for stroke longer than 2 meter, while for shorter<br />

than 2 meter, the value is derived from the graph shown below:<br />

fc<br />

1<br />

0.75<br />

0.5<br />

Technical Infomation<br />

The actual lifetime of the system (rails, slides, and rollers)<br />

depends on the applied load, but is also influenced by factors<br />

such as: correct lubrification, environmental conditions,<br />

assembly precision to avoid uncalculated component stress/<br />

wear and total cycle length.<br />

In order to estimate the expected system lifetime in km of<br />

operation, the following equation must be solved:<br />

L(Km) = 100 x (Co/P) 3 x fc/n x fa<br />

Where:<br />

Co = dynamic load coefficient of roller or slide<br />

P = is the equivalent load applied on the heaviest loaded roller<br />

or slide.<br />

For each single roller: P = P rad + (Pax / Co ax) x Co rad<br />

For the slide: P = P rad + (Pax / Coax + Mx / Mox + My / Moy<br />

+ Mz / Moz) x Co rad<br />

<strong>LINEAR</strong> PRECISION<br />

The linear precision of the running slide depends on the rail<br />

and, specifi cally, on the longitudinal parallelism between the<br />

raceways and precision of the surface to which they<br />

are mounted.<br />

As a result, two slide precision<br />

B<br />

values are determined, one<br />

referring to the surface the rails<br />

is fixed to (A) and the other (B) to<br />

the precision of supporting rail.<br />

Precision is achieved when the<br />

surfaces are aligned.<br />

When all screws are correctly<br />

tightened, the RRT rail aligns<br />

A<br />

with the fi xing surface, and this<br />

adds up to the construction linear<br />

precision of the same rail.<br />

When the RRT-rail is loose, it may result slightly curved.<br />

However, this does not give rise to any problem of alignment,<br />

once the rail is properly fixed.<br />

0.25<br />

0<br />

n = number of slides running on the same rail<br />

fa = coeffi cient depending on lubrication and environmental<br />

conditions. Recommended values are shown in the table below:<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

μm<br />

0<br />

fa<br />

0.7 - 1<br />

0.5 - 0.7<br />

0.5 - 0.1<br />

250 500 750 1000 1250 1500 1750 2000<br />

APPLICATION CONDITIONS<br />

500 1000 1500 2000 2500 3000 3500 4000<br />

B<br />

A<br />

Stroke<br />

mm<br />

Good lubrication, availability of self-lubricating rail<br />

wiper system, no dust accumulation and no pollutants,<br />

precise assembly<br />

Random lubrication, environmental dust, thermal<br />

fl uctuations, vibrations<br />

Low lubrication, high environmental pollution, strong<br />

thermal fl uctuations, high vibrations<br />

Stroke<br />

mm<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

148<br />

800.962.8979 • www.pacific-bearing.com