LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Simplicity ® Ball Bearings<br />

Technical Information<br />

Linear Motion Systems<br />

CLEARANCE & FIT<br />

Standard-type Simplicity ® linear ball bearings matched to a<br />

shaft that provides inadequate clearance may result in early<br />

bearing failure and/or rough linear motion. The clearance<br />

adjustable linear ball bearings and open linear ball bearings<br />

can be adjusted when assembled in the housing by controlling<br />

the housing bore. However, too much clearance will increase<br />

the deformation of the linear ball bearing, which will affect<br />

its precision and life. Therefore, the appropriate clearance<br />

between the ball bearing and shaft, and the appropriate linear<br />

ball bearing housing bore are required based on application.<br />

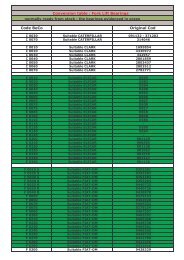

Table 2 shows recommended fit of the linear<br />

ball bearing:<br />

TABLE 2<br />

SHAFT & HOUSING<br />

To optimize performance of the Simplicity ® linear ball bearing<br />

it is recommended that a high precision shaft and pillow block<br />

are required.<br />

Shaft -<br />

The rolling balls in the Simplicity® linear ball bearing are<br />

in line contact with the shaft surface. Therefore, the shaft<br />

dimensions, tolerance, surface finish, and hardness greatly<br />

affect the performance of the linear ball bearing. The shaft<br />

should be manufactured to the following tolerances:<br />

1) Surface finish critically affects the smooth rolling of balls;<br />

Shaft surface finish should be 6-8 micro (RA# 7.2 to 10.8 a<br />

1.11 to 1 ratio).<br />

2) Shaft hardness should be HRC 60 to 64. Hardness less<br />

than HRC 60 will decreases the life/load, see page 126.<br />

3) Preload increases the frictional resistance slightly, If the<br />

preload is too tight, the deformation of the bearing sleeve<br />

will shorten the linear ball bearing’s life.<br />

Housing -<br />

There are a wide variety of housings differing in design,<br />

machining, and mounting. See Table 2 (above) and the<br />

following section on mounting requirements.<br />

Technical Information<br />

MOUNTING<br />

When inserting the linear ball bearing into the housing, do not<br />

hit the linear ball bearing on the end-retaining ring, but apply<br />

pressure either by hand or arbor on the linear ball bearing<br />

sleeve (See Fig.1) To insert the shaft into the mounted linear<br />

ball bearing, make sure the shaft is chamfered and be careful<br />

not to push on the balls by inserting the shaft at an angle.<br />

Note that if two shafts are used in parallel, the parallelism is<br />

an important factor to assure smooth linear movement and<br />

not damage the linear ball bearings.<br />

Examples of Mounting -<br />

The popular way to mount linear ball bearings is with a slight<br />

preload. Pacific Bearing recommends a slight clearance fitup<br />

to ensure proper life. The examples, Figs. 2 to 6, show<br />

the inserted linear ball bearing using a variety of retention<br />

methods.<br />

FIG. 1 FIG. 2 FIG. 3 FIG. 4 FIG. 5 FIG.6<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

88<br />

800.962.8979 • www.pacific-bearing.com