LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Simplicity ® Plane Bearings<br />

Product Overview - Polymer Series<br />

Linear Motion Systems<br />

MAIN ADVANTAGES<br />

Maintenance-free self-lubricated:<br />

PBC compounds lubricants in balanced ratios into the polymer<br />

matrix and ensure through fiberate mi cro-wear during running<br />

in for clean and continuous auto lubrication. During micro-wear<br />

a transfer coating is built enabling optimal sliding performance.<br />

The basic polymers and their additives already own good<br />

tribological properties.<br />

Long service life:<br />

The homogeneous structure of the compound plane bearings<br />

prevent thin run or wear layers which would shorten service<br />

life right from the beginning. The basic polymer with its mainly<br />

synthetic reinforcement additives forms an intimate matrix<br />

for other additives. There is no abrasive wear of the shafts<br />

because the commonly used glass fibers have been removed.<br />

Low friction:<br />

Static and dynamic coefficients of friction are close to each<br />

other due to the high amount of PTFE and other special<br />

additives in the compounds. Thus, we ensure stick-slip-free<br />

running at lower speeds. The plane bearing also runs with<br />

much less noise. The frictional behavior of the compound<br />

plane bearings depends mainly on tempe rature, sliding<br />

speeds, types of movement and loads. Surface structure<br />

and the circumstances of dry running or greasing standards<br />

substantially influence frictional behavior. Through the<br />

appropriate lubrication the coefficient of friction can be<br />

reduced even further.<br />

High dimensional stability:<br />

All compound plane bearings take in virtually no water, which<br />

can be disregarded to dimensional accuracy in connection<br />

with the installation. Fiber strengthening reduces thermal<br />

expansion/contraction and improves the press-fit at higher<br />

temperatures.<br />

PLANE BEARINGS FOR ALL APPLICATIONS<br />

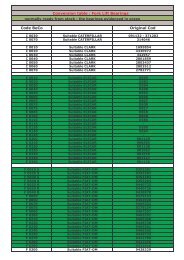

Standard Plane Bearings:<br />

Standard bearings are stocked in compounds<br />

A and E:<br />

• Bushings<br />

• Flanged bushings<br />

• Thrust washers<br />

• Bushings with integral seals<br />

You can select exact dimensions from the separate<br />

dimension table.<br />

Minimal wear:<br />

Compound plane bearings are extremely wear resistant in<br />

rotating and axial bearings as well as in hinge move ments<br />

under high loads.<br />

High loading capacity:<br />

Our compound plane bearings can withstand immense forces<br />

and pressures. As well as edge loads, which do not cause<br />

problems in contrast to common plane bearings made of<br />

non-fer rous metals or composite materials. Depending on the<br />

compound chosen, high pressures are also permissible.<br />

Broad temperature range:<br />

Depending on the material temperatures of -200°C/-328°F up<br />

to +250 °C can be withstood during application. Always check<br />

the compound specifications in each application with regard<br />

to temperature tolerances.<br />

Improved thermal conductivity:<br />

Polymer compound plane bearings show an improved thermal<br />

conductivity. Higher rpm/sfm during continuous operation are<br />

possible thanks to a better press-fit of the plane bearing in its<br />

housing. This is achieved through fiber strengthening.<br />

Pacifi c Bearing produces compound plane bearings through an injection molding process.<br />

We can help you select a suitable material for a specific application from our wide range of materials. Our technical staff will support<br />

you at every step of the way. PBC will find the best compound for your application – with regard to costs as well as effectiveness/<br />

performance.<br />

Whether you are looking for standard parts or custom/proprietary components we can provide standard plane bearings. Special<br />

components and seals are available as well.<br />

Plane Bearings with Integral Seals:<br />

Plane bearings with integral seals have proven superior in<br />

sustaining the basic advantages of our compound plane<br />

bearings even in tough environments.<br />

The advantages:<br />

• Integral seals keep away dirt and water from the bearing<br />

• Initial lubrication is suggested<br />

• Safe from corrosion<br />

As a standard we provide bearings with double-sided<br />

integral seals.<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

Plane Bearings<br />

800.962.8979 • www.pacific-bearing.com 93