LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Simplicity ® Ball Bearings<br />

Technical Information<br />

Linear Motion Systems<br />

FRICTIONAL RESISTANCE<br />

The static frictional resistance of the Simplicity ® linear system<br />

is so low that it is only slightly different from the kinetic<br />

frictional resistance, enabling smooth linear movement from<br />

low to high speeds. In general, the frictional resistance is<br />

expressed by the following equation.<br />

F = μ • W + f<br />

F : Frictional resistance<br />

W : Load weight<br />

μ : Coeffi cient of friction<br />

f : Sealing resistance<br />

The frictional resistance of each PBC linear system depends<br />

on the model, load weight, speed, and lubricant. The sealing<br />

resistance depends on the lip interference and lubricant,<br />

regardless of the load weight. The sealing resistance of one<br />

linear system is about 200 to 500 gf. The coefficient of friction<br />

depends on the load weight, moment load, and preload.<br />

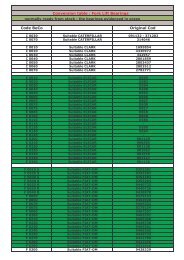

TABLE 5 - COEFFICIENT OF <strong>LINEAR</strong> SYSTEM FRICTIONS (μ)<br />

<strong>LINEAR</strong> SYSTEM TYPE MODELS COEFFICIENT OF FRICTION (μ)<br />

Linear Bearing JP, EP, IP 0.002 to 0.003<br />

AMBIENT WORKING TEMPERATURE<br />

The ambient working temperature range for each PBC linear<br />

system depends on the model. Consult PBC on use outside<br />

the recommended temperature range.<br />

Temperature conversion equation:<br />

C = 9 5 (F - 32) F = 32 + 5<br />

9 C<br />

TABLE 6 - AMBIENT WORKING TEMPERATURE<br />

<strong>LINEAR</strong> SYSTEM TYPE<br />

MODELS<br />

AMBIENT WORKING<br />

TEMPERATURE<br />

Linear Bushing JP, EP, IP -20 to 80°C, 176°F<br />

LUBRICATION AND DUST PREVENTION<br />

Using PBC linear systems without lubrication increases the<br />

abrasion of the rolling elements, shortening the life span. The<br />

PBC linear systems therefore require appropriate lubrication.<br />

For lubrication PBC recommends turbine oil conforming to<br />

ISO Standards G32 to G68 or lithium base soap grease No.2.<br />

Some PBC linear systems are sealed to block dust out and<br />

seal lubricant in. If used in a harsh or corrosive environment<br />

a protective cover should be used.<br />

Technical Information<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

800.962.8979 • www.pacific-bearing.com 91