LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

LINEAR MOTION SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Redi-Rail ® Compact Precision Drawer Slides<br />

Linear Motion Systems<br />

PRODUCT OVERVIEW<br />

The very compact RDQ drawer slides are designed for<br />

High-Tech telescopic applications with precise motorized<br />

movement, requiring constant smooth sliding performance<br />

with no play.<br />

The squared designed is obtained by using two RRT-rails with<br />

hardened honed raceways, as the rigid intermediate element,<br />

into which the slides are assembled. The RDQ drawer slides<br />

offer both high radial and axial load capacities.<br />

The rail/slide configuration allows the RDQ drawer slides to be<br />

mounted not only at the side, but also underneath the moving<br />

part, when there are space limitations at the sides, or to be used<br />

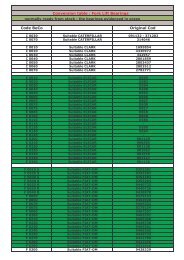

in typical vertical applications. See below tables and figures.<br />

In the case of horizontal panel extension, we recommend the<br />

use of a pair of RDR and RDQ, as the RDR can absorb some<br />

lateral structural misalignments on the vertical axis.<br />

RDQ system assures smooth extension for all kinds of<br />

automation applications with variable telescopic strokes,<br />

which until now have been troubled by common friction<br />

breakdown problems, during the ball-cage rephasing, when<br />

using typical drawer slides. Same rephase problem or<br />

even deformation of the ball-cages, occurs for all vertical<br />

applications, as the ball-cage in such drawer slides, constantly<br />

tend to move downwards, so extra friction is generated with<br />

each stroke, during the repositioning of the ball-cages.<br />

To assure maximum load capacity the drawer slides must<br />

be correctly orientation, assembled. The extended part must<br />

always be fixed to the shortest slide.<br />

All Redi-Rail ® Steel Rails guarantee maintenance free<br />

operation, thanks to strong raceway wipers and longitudinal<br />

seals for dust and impurity protection, and an integrated<br />

lubed for-life greasing system, assuring a constant thin layer<br />

of lubrication on the raceway surfaces.<br />

All Redi-Rail ® Compact Precision Drawer Slides are<br />

equipped with internal end-stops, only designed to drag the<br />

intermediate element. It is therefore highly recommended not<br />

to use these internal end of stroke travel limits as functional<br />

terminals; strong external end-stops must be added. Similarly<br />

to the RDR series, the RDQ’s stroke goes slightly beyond the<br />

overall length of the rail in closed position. The rails come<br />

with an overall black finish.<br />

Corad<br />

Coax<br />

Compact Precision Drawer Slides<br />

The data and specifi cations in this publication have been carefully compiled and are believed to be accurate and correct. However, it is the responsibility of the user to<br />

determine and ensure the suitability of Pacifi c Bearing® products for a specifi c application. Pacifi c Bearing’s only obligation will be to repair or replace without charge,<br />

any defective components if returned promptly. No liability is assumed beyond such replacement. *Consult www.pacifi c-bearing.com for the latest technical updates.<br />

800.962.8979 • www.pacific-bearing.com 157