advanced drainage system - Polypipe

advanced drainage system - Polypipe

advanced drainage system - Polypipe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

General Structural Design 3.2<br />

Pipe structural performance<br />

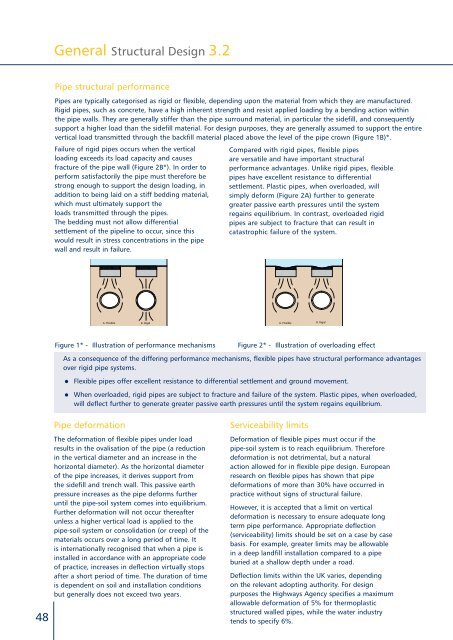

Pipes are typically categorised as rigid or flexible, depending upon the material from which they are manufactured.<br />

Rigid pipes, such as concrete, have a high inherent strength and resist applied loading by a bending action within<br />

the pipe walls. They are generally stiffer than Compressible Board the pipe surround material, Compressible in Board particular the sidefill, and consequently<br />

Trench<br />

Trench<br />

Support<br />

Support<br />

support a higher load than the sidefill material. For design purposes, they are generally assumed to support the entire<br />

Compressible Board<br />

Compressible Board<br />

vertical load transmitted through the backfill material placed above the level of the pipe crown (Figure 1B)*.<br />

Failure of rigid pipes occurs when the vertical<br />

100mm<br />

loading exceeds its load capacity and causes<br />

fracture of the pipe wall 150mm (Figure 150mm 2B*). In order to<br />

perform satisfactorily the pipe must therefore be<br />

strong enough to support the design loading, in<br />

addition to being laid on a stiff bedding material,<br />

150mm<br />

150mm<br />

150mm<br />

which must ultimately support the<br />

200mm<br />

200mm<br />

200mm<br />

loads transmitted through the pipes.<br />

150mm<br />

150mm<br />

The bedding must not allow differential<br />

settlement of the pipeline to occur, since this<br />

100mm<br />

would result in stress concentrations in the pipe<br />

150mm 150mm<br />

150mm<br />

wall and result in failure.<br />

1ess than 1.2m<br />

Minimum 150mm<br />

150mm<br />

1ess than 1.2m<br />

1ess than 1.2m<br />

Minimum 150mm<br />

150mm<br />

150mm<br />

150mm<br />

150mm<br />

150mm<br />

Compared with rigid pipes, flexible pipes<br />

100mm<br />

are versatile and have important structural<br />

performance advantages. Unlike rigid pipes, flexible<br />

pipes have excellent resistance to differential<br />

settlement. Plastic pipes, when overloaded, will<br />

simply deform (Figure 2A) further to generate<br />

150mm<br />

greater passive earth pressures until the <strong>system</strong><br />

200mm<br />

regains equilibrium. In contrast, overloaded rigid<br />

Concrete<br />

Concrete<br />

Grade<br />

150mm<br />

C20<br />

150mm<br />

Grade C20<br />

pipes are subject to fracture that can result in<br />

catastrophic failure of the <strong>system</strong>.<br />

100mm 150mm<br />

1ess than 1.2m<br />

150mm<br />

150mm<br />

150mm<br />

A. Flexible B. Rigid<br />

A. A. Flexible B. B. Rigid Rigid<br />

A. Flexible<br />

B. Rigid<br />

Figure 1* - Illustration of performance mechanisms<br />

Figure 2* - Illustration of overloading effect<br />

As a consequence of the differing performance mechanisms, flexible pipes have structural performance advantages<br />

over rigid pipe <strong>system</strong>s.<br />

• Flexible pipes offer excellent resistance to differential settlement and ground movement.<br />

•<br />

When overloaded, rigid pipes are subject to fracture and failure of the <strong>system</strong>. Plastic pipes, when overloaded,<br />

will deflect further to generate greater passive earth pressures until the <strong>system</strong> regains equilibrium.<br />

48<br />

Pipe deformation<br />

The deformation of flexible pipes under load<br />

results in the ovalisation of the pipe (a reduction<br />

in the vertical diameter and an increase in the<br />

horizontal diameter). As the horizontal diameter<br />

of the pipe increases, it derives support from<br />

the sidefill and trench wall. This passive earth<br />

pressure increases as the pipe deforms further<br />

until the pipe-soil <strong>system</strong> comes into equilibrium.<br />

Further deformation will not occur thereafter<br />

unless a higher vertical load is applied to the<br />

pipe-soil <strong>system</strong> or consolidation (or creep) of the<br />

materials occurs over a long period of time. It<br />

is internationally recognised that when a pipe is<br />

installed in accordance with an appropriate code<br />

of practice, increases in deflection virtually stops<br />

after a short period of time. The duration of time<br />

is dependent on soil and installation conditions<br />

but generally does not exceed two years.<br />

Serviceability limits<br />

Deformation of flexible pipes must occur if the<br />

pipe-soil <strong>system</strong> is to reach equilibrium. Therefore<br />

deformation is not detrimental, but a natural<br />

action allowed for in flexible pipe design. European<br />

research on flexible pipes has shown that pipe<br />

deformations of more than 30% have occurred in<br />

practice without signs of structural failure.<br />

However, it is accepted that a limit on vertical<br />

deformation is necessary to ensure adequate long<br />

term pipe performance. Appropriate deflection<br />

(serviceability) limits should be set on a case by case<br />

basis. For example, greater limits may be allowable<br />

in a deep landfill installation compared to a pipe<br />

buried at a shallow depth under a road.<br />

Deflection limits within the UK varies, depending<br />

on the relevant adopting authority. For design<br />

purposes the Highways Agency specifies a maximum<br />

allowable deformation of 5% for thermoplastic<br />

structured walled pipes, while the water industry<br />

tends to specify 6%.