advanced drainage system - Polypipe

advanced drainage system - Polypipe

advanced drainage system - Polypipe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

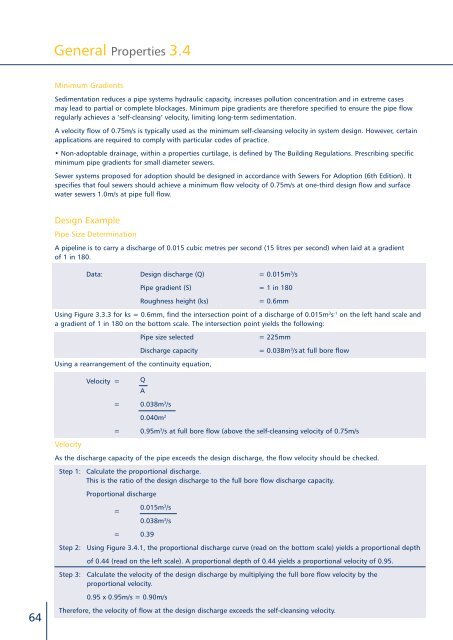

General Properties 3.4<br />

Minimum Gradients<br />

Sedimentation reduces a pipe <strong>system</strong>s hydraulic capacity, increases pollution concentration and in extreme cases<br />

may lead to partial or complete blockages. Minimum pipe gradients are therefore specified to ensure the pipe flow<br />

regularly achieves a ‘self-cleansing’ velocity, limiting long-term sedimentation.<br />

A velocity flow of 0.75m/s is typically used as the minimum self-cleansing velocity in <strong>system</strong> design. However, certain<br />

applications are required to comply with particular codes of practice.<br />

• Non-adoptable <strong>drainage</strong>, within a properties curtilage, is defined by The Building Regulations. Prescribing specific<br />

minimum pipe gradients for small diameter sewers.<br />

Sewer <strong>system</strong>s proposed for adoption should be designed in accordance with Sewers For Adoption (6th Edition). It<br />

specifies that foul sewers should achieve a minimum flow velocity of 0.75m/s at one-third design flow and surface<br />

water sewers 1.0m/s at pipe full flow.<br />

Design Example<br />

Pipe Size Determination<br />

A pipeline is to carry a discharge of 0.015 cubic metres per second (15 litres per second) when laid at a gradient<br />

of 1 in 180.<br />

Data: Design discharge (Q) = 0.015m 3 /s<br />

Pipe gradient (S) = 1 in 180<br />

Roughness height (ks)<br />

= 0.6mm<br />

Using Figure 3.3.3 for ks = 0.6mm, find the intersection point of a discharge of 0.015m 3 s -1 on the left hand scale and<br />

a gradient of 1 in 180 on the bottom scale. The intersection point yields the following:<br />

Pipe size selected<br />

Discharge capacity<br />

= 225mm<br />

= 0.038m 3 /s at full bore flow<br />

Using a rearrangement of the continuity equation,<br />

Velocity =<br />

Q<br />

A<br />

Velocity<br />

= 0.038m 3 /s<br />

0.040m 2<br />

= 0.95m 3 /s at full bore flow (above the self-cleansing velocity of 0.75m/s<br />

As the discharge capacity of the pipe exceeds the design discharge, the flow velocity should be checked.<br />

Step 1: Calculate the proportional discharge.<br />

This is the ratio of the design discharge to the full bore flow discharge capacity.<br />

Proportional discharge<br />

=<br />

0.015m 3 /s<br />

0.038m 3 /s<br />

= 0.39<br />

Step 2: Using Figure 3.4.1, the proportional discharge curve (read on the bottom scale) yields a proportional depth<br />

of 0.44 (read on the left scale). A proportional depth of 0.44 yields a proportional velocity of 0.95.<br />

Step 3: Calculate the velocity of the design discharge by multiplying the full bore flow velocity by the<br />

proportional velocity.<br />

0.95 x 0.95m/s = 0.90m/s<br />

64<br />

Therefore, the velocity of flow at the design discharge exceeds the self-cleansing velocity.