advanced drainage system - Polypipe

advanced drainage system - Polypipe

advanced drainage system - Polypipe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

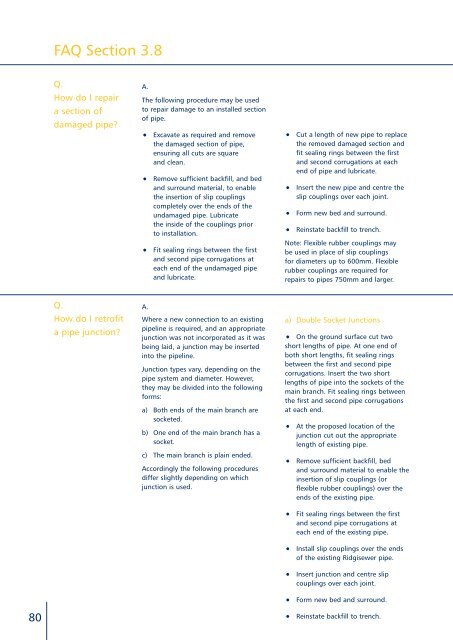

FAQ Section 3.8<br />

Q.<br />

How do I repair<br />

a section of<br />

damaged pipe?<br />

A.<br />

The following procedure may be used<br />

to repair damage to an installed section<br />

of pipe.<br />

• Excavate as required and remove<br />

the damaged section of pipe,<br />

ensuring all cuts are square<br />

and clean.<br />

• Remove sufficient backfill, and bed<br />

and surround material, to enable<br />

the insertion of slip couplings<br />

completely over the ends of the<br />

undamaged pipe. Lubricate<br />

the inside of the couplings prior<br />

to installation.<br />

• Fit sealing rings between the first<br />

and second pipe corrugations at<br />

each end of the undamaged pipe<br />

and lubricate.<br />

• Cut a length of new pipe to replace<br />

the removed damaged section and<br />

fit sealing rings between the first<br />

and second corrugations at each<br />

end of pipe and lubricate.<br />

• Insert the new pipe and centre the<br />

slip couplings over each joint.<br />

• Form new bed and surround.<br />

• Reinstate backfill to trench.<br />

Note: Flexible rubber couplings may<br />

be used in place of slip couplings<br />

for diameters up to 600mm. Flexible<br />

rubber couplings are required for<br />

repairs to pipes 750mm and larger.<br />

Q.<br />

How do I retrofit<br />

a pipe junction?<br />

A.<br />

Where a new connection to an existing<br />

pipeline is required, and an appropriate<br />

junction was not incorporated as it was<br />

being laid, a junction may be inserted<br />

into the pipeline.<br />

Junction types vary, depending on the<br />

pipe <strong>system</strong> and diameter. However,<br />

they may be divided into the following<br />

forms:<br />

a) Both ends of the main branch are<br />

socketed.<br />

b) One end of the main branch has a<br />

socket.<br />

c) The main branch is plain ended.<br />

Accordingly the following procedures<br />

differ slightly depending on which<br />

junction is used.<br />

a) Double Socket Junctions<br />

• On the ground surface cut two<br />

short lengths of pipe. At one end of<br />

both short lengths, fit sealing rings<br />

between the first and second pipe<br />

corrugations. Insert the two short<br />

lengths of pipe into the sockets of the<br />

main branch. Fit sealing rings between<br />

the first and second pipe corrugations<br />

at each end.<br />

• At the proposed location of the<br />

junction cut out the appropriate<br />

length of existing pipe.<br />

• Remove sufficient backfill, bed<br />

and surround material to enable the<br />

insertion of slip couplings (or<br />

flexible rubber couplings) over the<br />

ends of the existing pipe.<br />

• Fit sealing rings between the first<br />

and second pipe corrugations at<br />

each end of the existing pipe.<br />

• Install slip couplings over the ends<br />

of the existing Ridgisewer pipe.<br />

• Insert junction and centre slip<br />

couplings over each joint.<br />

80<br />

• Form new bed and surround.<br />

• Reinstate backfill to trench.