advanced drainage system - Polypipe

advanced drainage system - Polypipe

advanced drainage system - Polypipe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

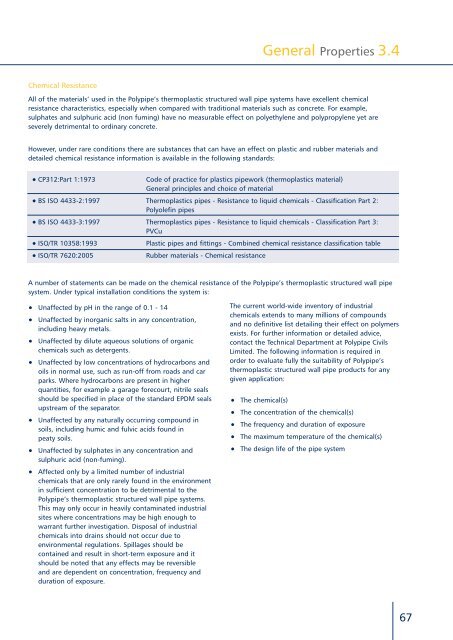

General Properties 3.4<br />

Chemical Resistance<br />

All of the materials’ used in the <strong>Polypipe</strong>’s thermoplastic structured wall pipe <strong>system</strong>s have excellent chemical<br />

resistance characteristics, especially when compared with traditional materials such as concrete. For example,<br />

sulphates and sulphuric acid (non fuming) have no measurable effect on polyethylene and polypropylene yet are<br />

severely detrimental to ordinary concrete.<br />

However, under rare conditions there are substances that can have an effect on plastic and rubber materials and<br />

detailed chemical resistance information is available in the following standards:<br />

• CP312:Part 1:1973<br />

Code of practice for plastics pipework (thermoplastics material)<br />

General principles and choice of material<br />

• BS ISO 4433-2:1997 Thermoplastics pipes - Resistance to liquid chemicals - Classification Part 2:<br />

Polyolefin pipes<br />

• BS ISO 4433-3:1997 Thermoplastics pipes - Resistance to liquid chemicals - Classification Part 3:<br />

PVCu<br />

• ISO/TR 10358:1993<br />

• ISO/TR 7620:2005<br />

Plastic pipes and fittings - Combined chemical resistance classification table<br />

Rubber materials - Chemical resistance<br />

A number of statements can be made on the chemical resistance of the <strong>Polypipe</strong>’s thermoplastic structured wall pipe<br />

<strong>system</strong>. Under typical installation conditions the <strong>system</strong> is:<br />

• Unaffected by pH in the range of 0.1 - 14<br />

• Unaffected by inorganic salts in any concentration,<br />

including heavy metals.<br />

• Unaffected by dilute aqueous solutions of organic<br />

chemicals such as detergents.<br />

• Unaffected by low concentrations of hydrocarbons and<br />

oils in normal use, such as run-off from roads and car<br />

parks. Where hydrocarbons are present in higher<br />

quantities, for example a garage forecourt, nitrile seals<br />

should be specified in place of the standard EPDM seals<br />

upstream of the separator.<br />

• Unaffected by any naturally occurring compound in<br />

soils, including humic and fulvic acids found in<br />

peaty soils.<br />

• Unaffected by sulphates in any concentration and<br />

sulphuric acid (non-fuming).<br />

• Affected only by a limited number of industrial<br />

chemicals that are only rarely found in the environment<br />

in sufficient concentration to be detrimental to the<br />

<strong>Polypipe</strong>’s thermoplastic structured wall pipe <strong>system</strong>s.<br />

This may only occur in heavily contaminated industrial<br />

sites where concentrations may be high enough to<br />

warrant further investigation. Disposal of industrial<br />

chemicals into drains should not occur due to<br />

environmental regulations. Spillages should be<br />

contained and result in short-term exposure and it<br />

should be noted that any effects may be reversible<br />

and are dependent on concentration, frequency and<br />

duration of exposure.<br />

The current world-wide inventory of industrial<br />

chemicals extends to many millions of compounds<br />

and no definitive list detailing their effect on polymers<br />

exists. For further information or detailed advice,<br />

contact the Technical Department at <strong>Polypipe</strong> Civils<br />

Limited. The following information is required in<br />

order to evaluate fully the suitability of <strong>Polypipe</strong>’s<br />

thermoplastic structured wall pipe products for any<br />

given application:<br />

• The chemical(s)<br />

• The concentration of the chemical(s)<br />

• The frequency and duration of exposure<br />

• The maximum temperature of the chemical(s)<br />

• The design life of the pipe <strong>system</strong><br />

67