advanced drainage system - Polypipe

advanced drainage system - Polypipe

advanced drainage system - Polypipe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

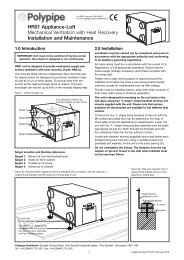

General Site Instructions 3.5<br />

Jointing Instructions<br />

This advice applies to all <strong>Polypipe</strong> structured walled thermoplastic pipes,<br />

seals and fittings. Note that sealing rings and lubricant may not be required<br />

for unsealed <strong>system</strong>s.<br />

Components from other manufacturers’ <strong>system</strong>s should not be used without<br />

the written permission of <strong>Polypipe</strong> Civils Limited. <strong>Polypipe</strong> Civils Limited does<br />

not guarantee any part of <strong>system</strong>s in which unauthorised components have<br />

been used.<br />

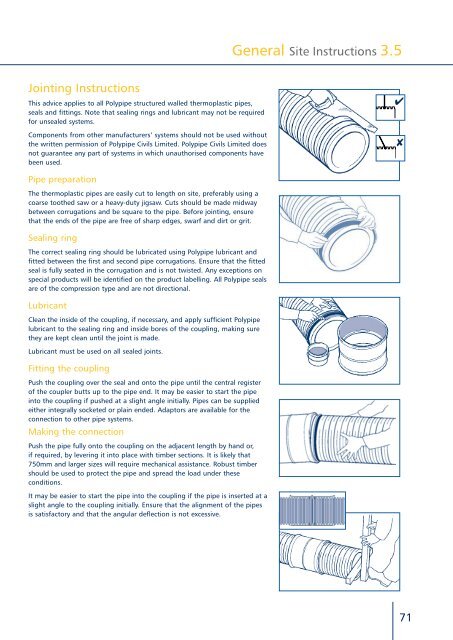

✔<br />

✘<br />

Pipe preparation<br />

The thermoplastic pipes are easily cut to length on site, preferably using a<br />

coarse toothed saw or a heavy-duty jigsaw. Cuts should be made midway<br />

between corrugations and be square to the pipe. Before jointing, ensure<br />

that the ends of the pipe are free of sharp edges, swarf and dirt or grit.<br />

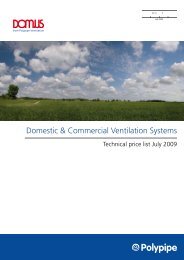

Sealing ring<br />

The correct sealing ring should be lubricated using <strong>Polypipe</strong> lubricant and<br />

fitted between the first and second pipe corrugations. Ensure that the fitted<br />

seal is fully seated in the corrugation and is not twisted. Any exceptions on<br />

special products will be identified on the product labelling. All <strong>Polypipe</strong> seals<br />

are of the compression type and are not directional.<br />

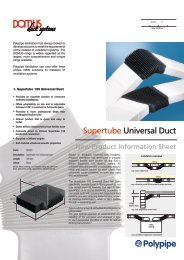

Lubricant<br />

Clean the inside of the coupling, if necessary, and apply sufficient <strong>Polypipe</strong><br />

lubricant to the sealing ring and inside bores of the coupling, making sure<br />

they are kept clean until the joint is made.<br />

Lubricant must be used on all sealed joints.<br />

Fitting the coupling<br />

Push the coupling over the seal and onto the pipe until the central register<br />

of the coupler butts up to the pipe end. It may be easier to start the pipe<br />

into the coupling if pushed at a slight angle initially. Pipes can be supplied<br />

either integrally socketed or plain ended. Adaptors are available for the<br />

connection to other pipe <strong>system</strong>s.<br />

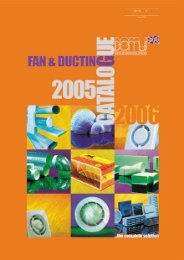

Making the connection<br />

Push the pipe fully onto the coupling on the adjacent length by hand or,<br />

if required, by levering it into place with timber sections. It is likely that<br />

750mm and larger sizes will require mechanical assistance. Robust timber<br />

should be used to protect the pipe and spread the load under these<br />

conditions.<br />

It may be easier to start the pipe into the coupling if the pipe is inserted at a<br />

slight angle to the coupling initially. Ensure that the alignment of the pipes<br />

is satisfactory and that the angular deflection is not excessive.<br />

71