Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

magnetic confinement (cont’d.)<br />

progress report<br />

2010<br />

011<br />

1.1 FTU Facility<br />

Summary of the machine operation<br />

The first experimental campaign started at the end of March but it was imme<strong>di</strong>ately stopped due to a leak<br />

in the vacuum chamber. After that a long series of vacuum problems prevented operations from being<br />

restarted until mid–June. The experimental campaign went on until the end of June, when it was closed due<br />

to problems to the motor flywheel generator (MFG1) chiller.<br />

The restart of the machine, originally scheduled for the end of October, began mid November, but,<br />

unfortunately, the 141 pulses done (51 of which for plant tests) turned out to be useless for the experimental<br />

campaign, because of several hardware failures. The main problem encountered was a broken electronic card<br />

of the Programmable High Speed Controller (PHSC) which controls the poloidal power supplies: since it<br />

required long time for reparation, this led to the end of the experimental campaign.<br />

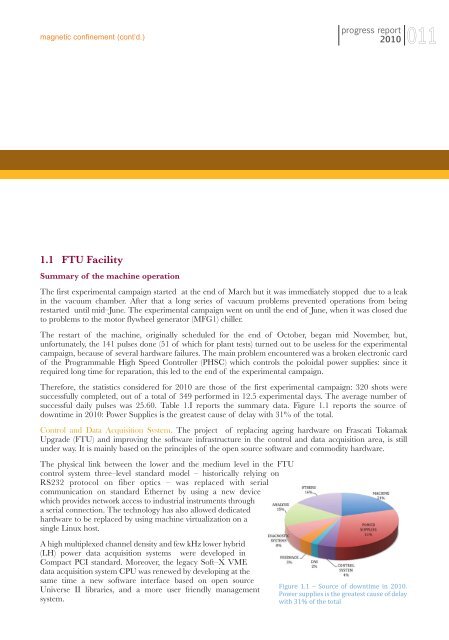

Therefore, the statistics considered for 2010 are those of the first experimental campaign: 320 shots were<br />

successfully completed, out of a total of 349 performed in 12.5 experimental days. The average number of<br />

successful daily pulses was 25.60. Table 1.I reports the summary data. Figure 1.1 reports the source of<br />

downtime in 2010: Power Supplies is the greatest cause of delay with 31% of the total.<br />

Control and Data Acquisition System. The project of replacing ageing hardware on Frascati Tokamak<br />

Upgrade (FTU) and improving the software infrastructure in the control and data acquisition area, is still<br />

under way. It is mainly based on the principles of the open source software and commo<strong>di</strong>ty hardware.<br />

The physical link between the lower and the me<strong>di</strong>um level in the FTU<br />

control system three–level standard model – historically relying on<br />

RS232 protocol on fiber optics – was replaced with serial<br />

communication on standard Ethernet by using a new device<br />

which provides network access to industrial instruments through<br />

a serial connection. The technology has also allowed de<strong>di</strong>cated<br />

hardware to be replaced by using machine virtualization on a<br />

single Linux host.<br />

A high multiplexed channel density and few kHz lower hybrid<br />

(LH) power data acquisition systems were developed in<br />

Compact PCI standard. Moreover, the legacy Soft–X VME<br />

data acquisition system CPU was renewed by developing at the<br />

same time a new software interface based on open source<br />

Universe II libraries, and a more user friendly management<br />

system.<br />

Figure 1.1 – Source of downtime in 2010.<br />

Power supplies is the greatest cause of delay<br />

with 31% of the total