Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

technology programme (cont’d.)<br />

progress report<br />

2010<br />

081<br />

acceptable to avoid unscrewing torque to be higher than<br />

80 Nm has been assessed for the bolts considered.<br />

Further analyses will be carried out in 2011 to investigate the<br />

potential influence of the screw length of engagement on the<br />

bolt connection thermo–mechanical performances, in<br />

presence of neutron swelling.<br />

3) Bolting seizure and the pre–stress tests. This activity is addressed to<br />

select suitable materials for bolts with the objective to prevent<br />

their seizure or relaxation. The first test was performed early<br />

in 2010, by using the test section shown in figure 3.54, and due<br />

to the bad results (all the bolts broke after an exposure of 1000<br />

hrs at 350°C) the experiment will be repeated in 2011.<br />

4) Validation of the skate system concept. This task is focused at<br />

evaluating the performance and the reliability of the skate<br />

system. In 2010 the following activities were performed:<br />

• Control and DAQ systems design was completed;<br />

• A set of sensors (extensometers) to perform a preliminary<br />

test on the BP already available in DRP were purchased<br />

and delivered.<br />

The setting up of the experiment will start early in 2011.<br />

The RH tasks were focussed on the validation of the cleaning<br />

procedure for the removal of sticked lithium metal from steel. In<br />

detail:<br />

• Cleaning procedure. In order to clean up steel specimens from<br />

sticked liquid metals, at <strong>ENEA</strong> Brasimone a mixed low aci<strong>di</strong>c<br />

solution was developed. It consists of: acetic acid [1N]<br />

(CH 3<br />

COOH)+hydrogen peroxide (H 2<br />

O 2<br />

)+Ethanol<br />

(CH 3<br />

CH 2<br />

OH) with the same ratio (1:1:1).<br />

This cleaning solution has been used at room temperature, for<br />

cleaning Li, PbLi, Pb, LBE and, accor<strong>di</strong>ng to weight<br />

measurements and electronic microscopy, no steels' kind<br />

(ferritic or martensitic or austenitic) have ever been attacked or<br />

mo<strong>di</strong>fied or corroded due to the treatment.<br />

This cleaning solution can be used both by immersion or<br />

spraying over a <strong>di</strong>rty surface.<br />

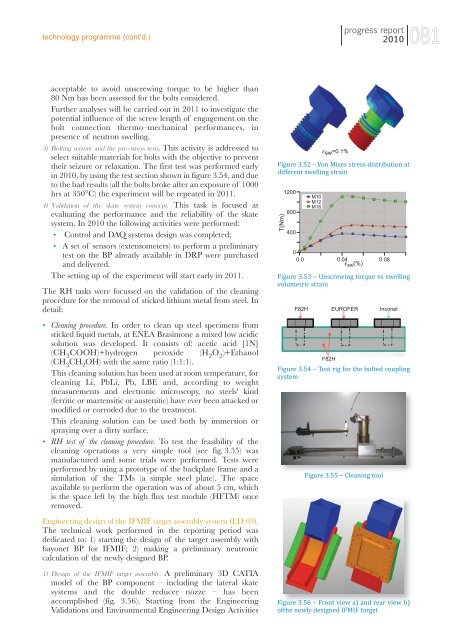

• RH test of the cleaning procedure. To test the feasibility of the<br />

cleaning operations a very simple tool (see fig. 3.55) was<br />

manufactured and some trials were performed. Tests were<br />

performed by using a prototype of the backplate frame and a<br />

simulation of the TMs (a simple steel plate). The space<br />

available to perform the operation was of about 5 cm, which<br />

is the space left by the high flux test module (HFTM) once<br />

removed.<br />

Engineering design of the IFMIF target assembly system (ED 03).<br />

The technical work performed in the reporting period was<br />

de<strong>di</strong>cated to: 1) starting the design of the target assembly with<br />

bayonet BP for IFMIF; 2) making a preliminary neutronic<br />

calculation of the newly designed BP.<br />

1) Design of the IFMIF target assembly. A preliminary 3D CATIA<br />

model of the BP component – inclu<strong>di</strong>ng the lateral skate<br />

systems and the double reducer nozze – has been<br />

accomplished (fig. 3.56). Starting from the Engineering<br />

Validations and Environmental Engineering Design Activities<br />

εsw=0.1%<br />

Figure 3.52 – Von Mises stress <strong>di</strong>stribution at<br />

<strong>di</strong>fferent swelling strain<br />

T(Nm)<br />

1200<br />

800<br />

400<br />

0<br />

0.0<br />

M10<br />

M12<br />

M16<br />

0.04 0.08<br />

ε sw (%)<br />

Figure 3.53 – Unscrewing torque vs swelling<br />

volumetric strain<br />

F82H<br />

F82H<br />

EUROFER<br />

Inconel<br />

Figure 3.54 – Test rig for the bolted coupling<br />

system<br />

Figure 3.55 – Cleaning tool<br />

Figure 3.56 – Front view a) and rear view b)<br />

ofthe newly designed IFMIF target