Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

Prime pagine RA2010FUS:Copia di Layout 1 - ENEA - Fusione

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

magnetic confinement (cont’d.)<br />

progress report<br />

2010<br />

025<br />

scan in gain should also be applied, though this technique has to be<br />

fully proven in laboratory.<br />

256<br />

Now the gas detector is at the Frascati laboratories in order to continue<br />

the characterization and prepare irra<strong>di</strong>ation tests under 2.5 MeV<br />

neutron flux using the Frascati Neutron Generator (FNG) facility and<br />

in environment with ra<strong>di</strong>ofrequency interference (the FTU’s hall).<br />

Since this detector has three GEM foils for the electron amplification,<br />

it could provide the advantage to be less sensitive to neutrons and<br />

gammas as compared with the single stage one. These tests are<br />

scheduled for February 2011.<br />

2) Feasibility stu<strong>di</strong>es of polycapillary lenses. Polycapillary lenses [1.14]<br />

have been stu<strong>di</strong>ed in laboratory for preliminary characterization, with<br />

the aim of using them in SXR <strong>di</strong>agnostics such as imaging and<br />

tomography [1.15]. The first tests were performed to characterize the<br />

polycapillary lenses (convergence, <strong>di</strong>vergence, efficiency, spectral<br />

<strong>di</strong>spersion, aberrations and so on) in the SXR range 5–25 keV and for<br />

<strong>di</strong>stances much larger than the optical focal length of the lenses, both<br />

for the detector and the source. A silicon based C–MOS imager<br />

(Me<strong>di</strong>pix 2) has been used as 2D detector and the micro focus x–ray<br />

tubes as “point–like” sources.<br />

The full lens has been characterized by using an electronic tube with a<br />

Mo anode powered at 25 kV, 150 μA (continuous spectra with the K α<br />

line of Mo at 17.4 keV in ad<strong>di</strong>tion), while the half lens by using an<br />

x–ray tube with a Cu anode and a Ni filter (K α<br />

line of Cu at 8.04 keV),<br />

powered at 15 kV, 300 μA. The images have been acquired with the<br />

Me<strong>di</strong>pix 2 [1.16]. In particular, the output focus of the full lens has<br />

been found by a scan of the <strong>di</strong>stance detector–lens. The intensity of the<br />

spot is found to be fairly Gaussian and the spot broadening is linear<br />

with the <strong>di</strong>stance (60 cm) much larger than the focal <strong>di</strong>stance (4.4 cm).<br />

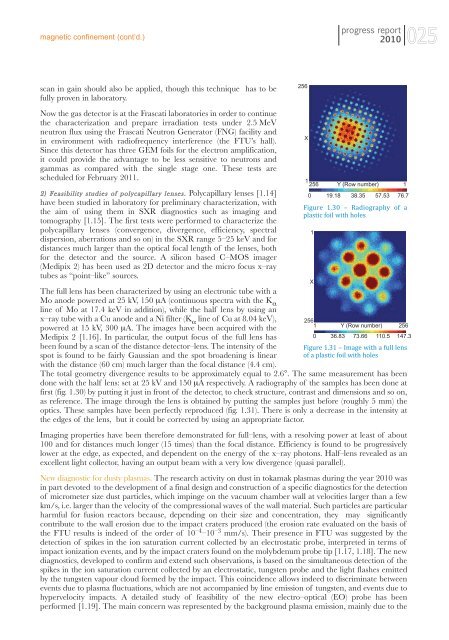

The total geometry <strong>di</strong>vergence results to be approximately equal to 2.6°. The same measurement has been<br />

done with the half lens: set at 25 kV and 150 μA respectively. A ra<strong>di</strong>ography of the samples has been done at<br />

first (fig. 1.30) by putting it just in front of the detector, to check structure, contrast and <strong>di</strong>mensions and so on,<br />

as reference. The image through the lens is obtained by putting the samples just before (roughly 5 mm) the<br />

optics. These samples have been perfectly reproduced (fig. 1.31). There is only a decrease in the intensity at<br />

the edges of the lens, but it could be corrected by using an appropriate factor.<br />

Imaging properties have been therefore demonstrated for full–lens, with a resolving power at least of about<br />

100 and for <strong>di</strong>stances much longer (15 times) than the focal <strong>di</strong>stance. Efficiency is found to be progressively<br />

lower at the edge, as expected, and dependent on the energy of the x–ray photons. Half–lens revealed as an<br />

excellent light collector, having an output beam with a very low <strong>di</strong>vergence (quasi parallel).<br />

New <strong>di</strong>agnostic for dusty plasmas. The research activity on dust in tokamak plasmas during the year 2010 was<br />

in part devoted to the development of a final design and construction of a specific <strong>di</strong>agnostics for the detection<br />

of micrometer size dust particles, which impinge on the vacuum chamber wall at velocities larger than a few<br />

km/s, i.e. larger than the velocity of the compressional waves of the wall material. Such particles are particular<br />

harmful for fusion reactors because, depen<strong>di</strong>ng on their size and concentration, they may significantly<br />

contribute to the wall erosion due to the impact craters produced (the erosion rate evaluated on the basis of<br />

the FTU results is indeed of the order of 10 –4 –10 –3 mm/s). Their presence in FTU was suggested by the<br />

detection of spikes in the ion saturation current collected by an electrostatic probe, interpreted in terms of<br />

impact ionization events, and by the impact craters found on the molybdenum probe tip [1.17, 1.18]. The new<br />

<strong>di</strong>agnostics, developed to confirm and extend such observations, is based on the simultaneous detection of the<br />

spikes in the ion saturation current collected by an electrostatic, tungsten probe and the light flashes emitted<br />

by the tungsten vapour cloud formed by the impact. This coincidence allows indeed to <strong>di</strong>scriminate between<br />

events due to plasma fluctuations, which are not accompanied by line emission of tungsten, and events due to<br />

hypervelocity impacts. A detailed study of feasibility of the new electro–optical (EO) probe has been<br />

performed [1.19]. The main concern was represented by the background plasma emission, mainly due to the<br />

X<br />

1<br />

256 Y (Row number) 1<br />

0<br />

19.18 38.35 57.53 76.7<br />

Figure 1.30 – Ra<strong>di</strong>ography of a<br />

plastic foil with holes<br />

1<br />

X<br />

256<br />

1 Y (Row number)<br />

256<br />

0 36.83 73.66 110.5 147.3<br />

Figure 1.31 – Image with a full lens<br />

of a plastic foil with holes