0870 849 8057 USERS G 24, 30 - Ideal Heating

0870 849 8057 USERS G 24, 30 - Ideal Heating

0870 849 8057 USERS G 24, 30 - Ideal Heating

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

sERVICINg<br />

34<br />

38 sERVICINg sChEDULE<br />

sERVICINg<br />

For the very latest copy of literature for specification & maintenance practices, visit our website www.idealheating.com, where you<br />

will be able to download the relevant information. N.B. Technical Bulletins are also available on our website.<br />

Warning. always turn OFF the gas supply at the gas service cock, and switch OFF and disconnect the electricity<br />

supply to the appliance before servicing.<br />

Combustion testing must be carried out by a competent person using a combustion analyser conforming to Bs7927.<br />

To ensure the continued safe and efficient operation of the appliance it is recommended that it is checked at regular intervals and<br />

serviced as necessary. The frequency of servicing will depend upon the installation condition and usage but should be carried out<br />

at least annually.<br />

It is the law that any service work must be carried out by a Gas Safe Registered Engineer. In IE service work must be carried out<br />

by a Registered Gas Installer (RGII).<br />

INspECTION<br />

1. Light the boiler and carry out a pre-service check, noting any<br />

operational faults.<br />

2. Check the flue terminal (and terminal guard if fitted) is undamaged<br />

and clear of any obstruction.<br />

3. Check all water and gas joints for signs of leakage. Remake any<br />

suspect joints ensuring a gas tightness check is carried out if<br />

applicable and the water system is correctly refilled, vented and<br />

re-pressurised.<br />

CLEaNINg pROCEDURE<br />

Note. In order to carry out either servicing or replacement of<br />

components the boiler front panel must be removed. Refer to<br />

Frame 39.<br />

1. Clean the main burner. Refer to frame 41.<br />

2. Clean the heat exchanger & condensate trap/siphon. Refer to<br />

Frames 42 & 43.<br />

3. Check the main injector for blockage or damage. Refer to Frame<br />

40.<br />

4. Check that the flue terminal is unobstructed and that the flue system<br />

is sealed correctly.<br />

ALSO IF THE DHW FLOW RATE IS IN QUESTION :-<br />

5. Check the DHW filter for blockage. Refer to Frame 69.<br />

The cleaning procedures are covered more fully in Frames 39-44 and<br />

MUST be carried out in sequence.<br />

IMpORTaNT.<br />

6. After completing the servicing or exchange of components always<br />

test for gas tightness.<br />

7. When work is complete the front panel MUST be correctly refitted,<br />

ensuring that a good seal is made.<br />

Do noT operaTe the boiler if the front panel is not<br />

fitted.<br />

8. If, for any reason, the condensate trap/siphon has been removed<br />

ensure the trap is refilled with water before<br />

reassembling.<br />

9. Check the gas consumption.<br />

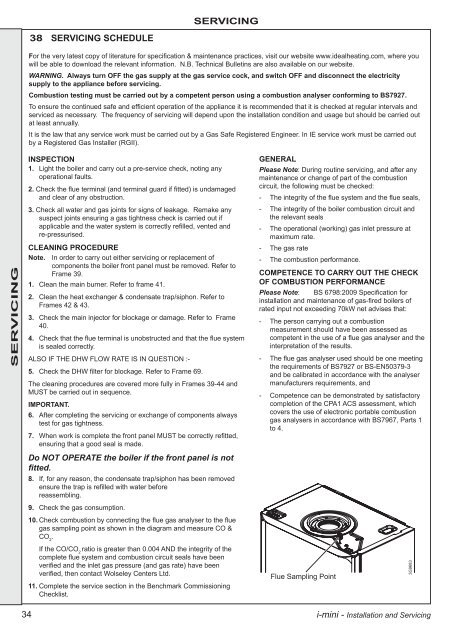

10. Check combustion by connecting the flue gas analyser to the flue<br />

gas sampling point as shown in the diagram and measure CO &<br />

CO . 2<br />

If the CO/CO 2 ratio is greater than 0.004 AND the integrity of the<br />

complete flue system and combustion circuit seals have been<br />

verified and the inlet gas pressure (and gas rate) have been<br />

verified, then contact Wolseley Centers Ltd.<br />

11. Complete the service section in the Benchmark Commissioning<br />

Checklist.<br />

gENERaL<br />

please note: During routine servicing, and after any<br />

maintenance or change of part of the combustion<br />

circuit, the following must be checked:<br />

- The integrity of the flue system and the flue seals,<br />

- The integrity of the boiler combustion circuit and<br />

the relevant seals<br />

- The operational (working) gas inlet pressure at<br />

maximum rate.<br />

- The gas rate<br />

- The combustion performance.<br />

COMpETENCE TO CaRRy OUT ThE ChECK<br />

OF COMBUsTION pERFORMaNCE<br />

please note: BS 6798:2009 Specification for<br />

installation and maintenance of gas-fired boilers of<br />

rated input not exceeding 70kW net advises that:<br />

- The person carrying out a combustion<br />

measurement should have been assessed as<br />

competent in the use of a flue gas analyser and the<br />

interpretation of the results.<br />

- The flue gas analyser used should be one meeting<br />

the requirements of BS7927 or BS-EN50379-3<br />

and be calibrated in accordance with the analyser<br />

manufacturers requirements, and<br />

- Competence can be demonstrated by satisfactory<br />

completion of the CPA1 ACS assessment, which<br />

covers the use of electronic portable combustion<br />

gas analysers in accordance with BS7967, Parts 1<br />

to 4.<br />

Flue Sampling Point<br />

i-mini - Installation and Servicing<br />

3G9683