Controllers - AGCO Parts

Controllers - AGCO Parts

Controllers - AGCO Parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A GUIDE TO CLEANING YOUR SPRAYERS<br />

Step-by-Step Instructions for Cleaning Equipment After Application<br />

Technical Pages<br />

1 Flush tank, hoses, boom and nozzles with clean<br />

water.<br />

2<br />

Prepare a cleaning solution using a Novartis-approved<br />

commercial tank cleaner, such as <strong>AGCO</strong> ® Dry Tank<br />

Cleaner. Read the cleanser label for the correct rate.<br />

Read the following sections for instructions on proper<br />

tank cleaning procedures. Do not use chlorine-based<br />

cleaners such as Clorox ® .<br />

3<br />

Use a pressure washer to clean the inside of the spray<br />

tank with this solution. Take care to wash all parts of<br />

the tank, including the inside top surface.<br />

4<br />

Completely fill the sprayer with the cleaning solution to<br />

ensure contact of the cleaning solution with all internal<br />

surfaces of the tank and plumbing. Start agitation in<br />

the sprayer and thoroughly recirculate the cleaning<br />

solution for at least 15 minutes. All visible deposits<br />

must be removed from the spraying system.<br />

5<br />

Flush hoses, spray lines and nozzles for at least one<br />

minute with cleaning solution.<br />

Tank-Rinsing Nozzles<br />

MULTIPLE<br />

SPRAY<br />

ORIFICES<br />

MULTIPLE<br />

SPRAY<br />

ORIFICES<br />

6<br />

7<br />

8<br />

9<br />

Note:<br />

Dispose of rinsate from steps 1–5 in an appropriate<br />

manner. Spray the cleaning solution on untreated<br />

corn or return to a rinsate tank for later use as<br />

makeup water for spraying corn.<br />

Repeat steps 2–5 again.<br />

Remove nozzles, screens and strainers and clean<br />

separately in the cleaning solution after completing<br />

the above procedures.<br />

Rinse the complete spraying system with clean<br />

water.<br />

1) If the tank is equipped with the proper number of<br />

correctly-mounted 360° tank-washing nozzles<br />

which are attached to a dedicated rinsing system,<br />

less than a full tank cleaning solution may be used.<br />

Use sufficient cleaning solution to thoroughly rinse<br />

all surfaces. Start the sprayer agitation and recirculate<br />

solution for at least 15 minutes. Flush the spray<br />

boom with the cleaning solution. Repeat the rinsing<br />

procedure 1–2 times.<br />

2) If the sprayer contains obvious residue buildup or<br />

when switching to a crop which is especially sensitive<br />

to the last herbicide used, follow step 4 above,<br />

even if a tank-rinsing system is in place.<br />

u Nozzles should rotate 360° so that all inside surfaces of<br />

the tank can be wetted by the spray. It is important that<br />

the inside top of the tank and all of the corners are in direct<br />

contact with rinsing spray.<br />

u The tank-rinsing system will include a separate tank<br />

which is used for holding nothing but cleaning solution.<br />

u Install at least two rinsing nozzles in each tank. One<br />

positioned on either side of the tank lid.<br />

u In sprayers with baffled tanks, use one nozzle per baffled<br />

section.<br />

Several companies manufacture special nozzles for rinsing<br />

spray tanks. These should be permanently mounted in<br />

the top of the spray tank. A properly-designed tank-rinsing<br />

system will have these characteristics:<br />

u Following rinsing system manufacturer’s guidelines for<br />

correct installation, operation, and maintenance of the<br />

equipment.<br />

u Routinely rinse the sprayer thoroughly with clean water or<br />

cleaning solution and drain all lines. Use of rinsing<br />

nozzles is no substitute for practicing complete cleaning<br />

practices.<br />

258<br />

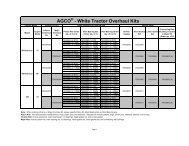

Please Note: For a complete <strong>AGCO</strong> part number; please add AG to the front of the six digit number.