10 table saw - Grizzly Industrial Inc.

10 table saw - Grizzly Industrial Inc.

10 table saw - Grizzly Industrial Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

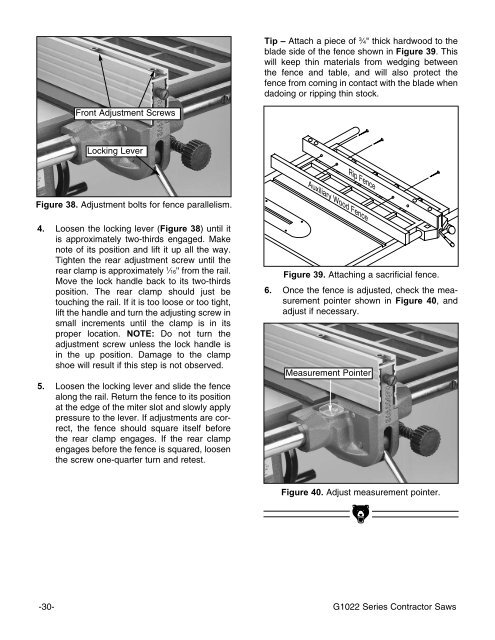

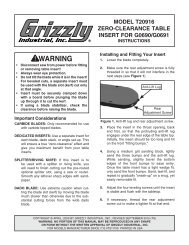

Tip – Attach a piece of 3 ⁄4" thick hardwood to theblade side of the fence shown in Figure 39. Thiswill keep thin materials from wedging betweenthe fence and <strong>table</strong>, and will also protect thefence from coming in contact with the blade whendadoing or ripping thin stock.Front Adjustment ScrewsLocking LeverFigure 38. Adjustment bolts for fence parallelism.4. Loosen the locking lever (Figure 38) until itis approximately two-thirds engaged. Makenote of its position and lift it up all the way.Tighten the rear adjustment screw until therear clamp is approximately 1 ⁄16'' from the rail.Move the lock handle back to its two-thirdsposition. The rear clamp should just betouching the rail. If it is too loose or too tight,lift the handle and turn the adjusting screw insmall increments until the clamp is in itsproper location. NOTE: Do not turn theadjustment screw unless the lock handle isin the up position. Damage to the clampshoe will result if this step is not observed.5. Loosen the locking lever and slide the fencealong the rail. Return the fence to its positionat the edge of the miter slot and slowly applypressure to the lever. If adjustments are correct,the fence should square itself beforethe rear clamp engages. If the rear clampengages before the fence is squared, loosenthe screw one-quarter turn and retest.Figure 39. Attaching a sacrificial fence.6. Once the fence is adjusted, check the measurementpointer shown in Figure 40, andadjust if necessary.Measurement PointerFigure 40. Adjust measurement pointer.-30- G<strong>10</strong>22 Series Contractor Saws