Technical Report for the Fort Knox Mine - Kinross Gold

Technical Report for the Fort Knox Mine - Kinross Gold

Technical Report for the Fort Knox Mine - Kinross Gold

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

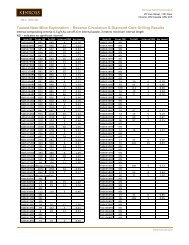

<strong>Fort</strong> <strong>Knox</strong> <strong>Mine</strong> <strong>Technical</strong> <strong>Report</strong>Pit optimization slope angles are based on inter-ramp angles from studies by two firms<strong>Gold</strong>er Associates and Call & Nicholas, Inc. Due to <strong>the</strong> “flat bottom” and centralgeometry of <strong>the</strong> <strong>Fort</strong> <strong>Knox</strong> orebody allowing <strong>for</strong> unique ramp access opportunities,overall slopes in <strong>the</strong> pit optimization were not flattened beyond inter-ramp angles. Acomplex slope model was developed utilizing <strong>the</strong> location of <strong>the</strong> granite-schist contact.Slopes used in <strong>the</strong> schist were 37 0 on <strong>the</strong> south wall, 42º in <strong>the</strong> southwest corner, 40º on<strong>the</strong> north and northwest walls, and 45º on <strong>the</strong> east wall. Slopes in <strong>the</strong> underlying granitewere set at 45º. The 37º and 45º angles on <strong>the</strong> south wall schist and granite,respectively, are not an exact match to <strong>the</strong> design strategy suggested by Call &Nicholas; however, this would not influence <strong>the</strong> pit optimization, since <strong>the</strong> south wall wasconstrained by practical mining pushback limitations.Previous years’ optimizations were limited by NOAA’s land holdings on <strong>the</strong> west side of<strong>the</strong> pit. Negotiations with NOAA to obtain a westward extension of FGMI’s land holdingswere completed in 2007 allowing <strong>the</strong> inclusion of additional material as mineral reserveand mineral resource.Using <strong>the</strong> <strong>Mine</strong>Sight software package, a Lerchs-Grossmann pit optimization was run at$550 gold price using no discount rate. A check was per<strong>for</strong>med by <strong>Kinross</strong> <strong>Technical</strong>Services using Whittle software and methodology, and <strong>the</strong> pit shell with <strong>the</strong> optimal NPVwas found to vary in total tonnage from <strong>the</strong> $550 <strong>Mine</strong>Sight pit by less than 1.7%. Afinal pit was <strong>the</strong>n designed using <strong>the</strong> optimized pit outline as a guide, and closely follows<strong>the</strong> $525 per ounce pit optimization on <strong>the</strong> north and east sides. A very large varianceexists between <strong>the</strong> optimization and <strong>the</strong> pit design, due to size limitations of practicalpushbacks on <strong>the</strong> sou<strong>the</strong>ast and east sides, and land position restrictions on <strong>the</strong> westside.17.4 Production ReconciliationThe current mineral model <strong>for</strong> <strong>Fort</strong> <strong>Knox</strong> was reconciled to actual mining to provide anindication as to how well <strong>the</strong> current resource and reserve model predicts <strong>the</strong> tonnageand grade of <strong>the</strong> mineralization. Table 17-5 displays <strong>the</strong> reconciliation of <strong>the</strong> A-ore model64