Technical Report for the Fort Knox Mine - Kinross Gold

Technical Report for the Fort Knox Mine - Kinross Gold

Technical Report for the Fort Knox Mine - Kinross Gold

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

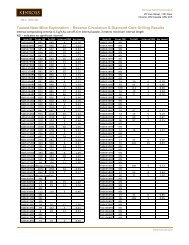

<strong>Fort</strong> <strong>Knox</strong> <strong>Mine</strong> <strong>Technical</strong> <strong>Report</strong>• All designs utilized toe and crest contours.The ultimate pit was designed from a US $525 per ounce pit optimization, which waslimited by practical pushback size limitations on <strong>the</strong> south side.On <strong>the</strong> south wall, <strong>the</strong> zone of alteration 2-3 benches above and below <strong>the</strong> schist-granitecontact has been identified as a zone that requires more conservative slopes. In <strong>the</strong>seareas, design includes slope angles as low as 32°, as well as 90 ft stepout berms up to130 ft above <strong>the</strong> contact. General design guidelines were documented by geotechnicalconsultants Call & Nicholas (“CNI”) in October 2006, and FGMI technical staff haveworked closely with CNI in areas that require local design exceptions.23.1.3 O<strong>the</strong>r ConsiderationsIn 1996, a 1.3 million short ton slope failure developed in <strong>the</strong> central south wall above<strong>the</strong> granite-schist contact. The slide was stabilized with mining set backs at <strong>the</strong> toe of <strong>the</strong>failure. <strong>Gold</strong>er Associates Inc. was not able to develop a predictive slope stability model,because of <strong>the</strong> complex structure in <strong>the</strong> area, so a range of potential slopes wasrecommended. At a design angle of 28 o <strong>Gold</strong>er predicted little chance of failure and, at adesign angle 35 o , a high chance of failure was predicted. In 2005 Call and Nicholas Inc.was retained to develop a recommendation <strong>for</strong> <strong>the</strong> slope failure area, with continuingwork resulting in design parameters described briefly in <strong>the</strong> section above. Ground waterwas believed to be a contributing factor to <strong>the</strong> failure, and a dewatering program is inplace.The dewatering department drilled two dewatering wells in 2007. The wells target waterin advancing areas of mining. There are a total of twenty-one groundwater dewateringwells, with a potential pumping capacity of 1,470 gallons per minute (gpm). Eighteen of<strong>the</strong> wells were active in and around <strong>the</strong> pit, as well as one well north of <strong>the</strong> pit, near <strong>the</strong>causeway. The average annual pumping rate <strong>for</strong> wells in <strong>the</strong> pit area was 355 gpm, withan additional 650 gpm from <strong>the</strong> well north of <strong>the</strong> pit, <strong>for</strong> a total average dewatering rateof approximately 1005 gpm <strong>for</strong> 2007. The total pumping rate shows a 35% decrease in75