150/250 Wheel Balancer - aesco

150/250 Wheel Balancer - aesco

150/250 Wheel Balancer - aesco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

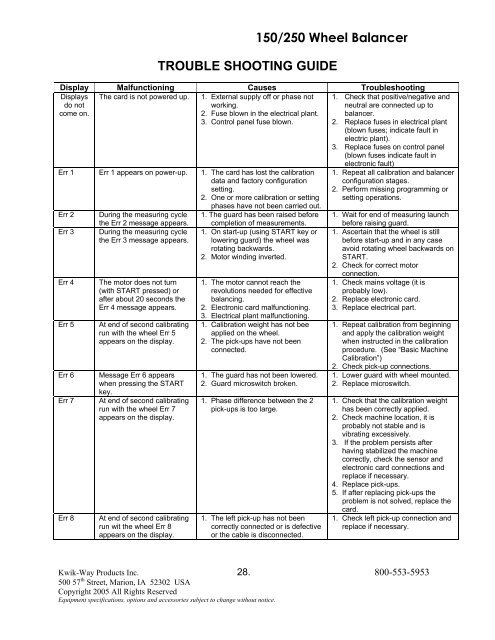

<strong>150</strong>/<strong>250</strong> <strong>Wheel</strong> <strong>Balancer</strong>TROUBLE SHOOTING GUIDEDisplay Malfunctioning Causes TroubleshootingDisplaysdo notcome on.The card is not powered up.1. External supply off or phase notworking.2. Fuse blown in the electrical plant.3. Control panel fuse blown.Err 1 Err 1 appears on power-up. 1. The card has lost the calibrationdata and factory configurationsetting.2. One or more calibration or settingphases have not been carried out.Err 2 During the measuring cycle 1. The guard has been raised beforeErr 3Err 4Err 5Err 6Err 7Err 8the Err 2 message appears.During the measuring cyclethe Err 3 message appears.The motor does not turn(with START pressed) orafter about 20 seconds theErr 4 message appears.At end of second calibratingrun with the wheel Err 5appears on the display.Message Err 6 appearswhen pressing the STARTkey.At end of second calibratingrun with the wheel Err 7appears on the display.At end of second calibratingrun wit the wheel Err 8appears on the display.completion of measurements.1. On start-up (using START key orlowering guard) the wheel wasrotating backwards.2. Motor winding inverted.1. The motor cannot reach therevolutions needed for effectivebalancing.2. Electronic card malfunctioning.3. Electrical plant malfunctioning.1. Calibration weight has not beeapplied on the wheel.2. The pick-ups have not beenconnected.1. The guard has not been lowered.2. Guard microswitch broken.1. Phase difference between the 2pick-ups is too large.1. The left pick-up has not beencorrectly connected or is defectiveor the cable is disconnected.1. Check that positive/negative andneutral are connected up tobalancer.2. Replace fuses in electrical plant(blown fuses; indicate fault inelectric plant).3. Replace fuses on control panel(blown fuses indicate fault inelectronic fault)1. Repeat all calibration and balancerconfiguration stages.2. Perform missing programming orsetting operations.1. Wait for end of measuring launchbefore raising guard.1. Ascertain that the wheel is stillbefore start-up and in any caseavoid rotating wheel backwards onSTART.2. Check for correct motorconnection.1. Check mains voltage (it isprobably low).2. Replace electronic card.3. Replace electrical part.1. Repeat calibration from beginningand apply the calibration weightwhen instructed in the calibrationprocedure. (See “Basic MachineCalibration”)2. Check pick-up connections.1. Lower guard with wheel mounted.2. Replace microswitch.1. Check that the calibration weighthas been correctly applied.2. Check machine location, it isprobably not stable and isvibrating excessively.3. If the problem persists afterhaving stabilized the machinecorrectly, check the sensor andelectronic card connections andreplace if necessary.4. Replace pick-ups.5. If after replacing pick-ups theproblem is not solved, replace thecard.1. Check left pick-up connection andreplace if necessary.Kwik-Way Products Inc. 28. 800-553-5953500 57 th Street, Marion, IA 52302 USACopyright 2005 All Rights ReservedEquipment specifications, options and accessories subject to change without notice.