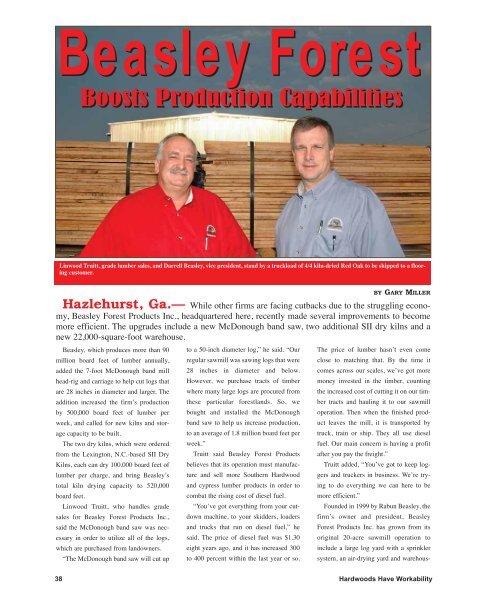

Beasley ForestBoosts Production CapabilitiesLinwood Truitt, grade lumber sales, and Darrell Beasley, vice president, stand by a truckload of 4/4 kiln-dried Red Oak to be shipped to a flooringcustomer.Hazlehurst, Ga.— While other firms are facing cutbacks due to the struggling economy,Beasley Forest Products Inc., headquartered here, recently made several improvements to becomemore efficient. The upgrades include a new McDonough band saw, two additional SII dry kilns and anew 22,000-square-foot warehouse.Beasley, which produces more than 90million board feet of lumber annually,added the 7-foot McDonough band millhead-rig and carriage to help cut logs thatare 28 inches in diameter and larger. Theaddition increased the firm’s productionby 500,000 board feet of lumber perweek, and called for new kilns and storagecapacity to be built.The two dry kilns, which were orderedfrom the Lexington, N.C.-based SII DryKilns, each can dry 100,000 board feet oflumber per charge, and bring Beasley’stotal kiln drying capacity to 520,000board feet.Linwood Truitt, who handles gradesales for Beasley Forest Products Inc.,said the McDonough band saw was necessaryin order to utilize all of the logs,which are purchased from landowners.“The McDonough band saw will cut upto a 50-inch diameter log,” he said. “Ourregular sawmill was sawing logs that were28 inches in diameter and below.However, we purchase tracts of timberwhere many large logs are procured fromthese particular forestlands. So, webought and installed the McDonoughband saw to help us increase production,to an average of 1.8 million board feet perweek.”Truitt said Beasley Forest Productsbelieves that its operation must manufactureand sell more Southern Hardwoodand cypress lumber products in order tocombat the rising cost of diesel fuel.“You’ve got everything from your cutdownmachine, to your skidders, loadersand trucks that run on diesel fuel,” hesaid. The price of diesel fuel was $1.30eight years ago, and it has increased 300to 400 percent within the last year or so.BY GARY MILLERThe price of lumber hasn’t even comeclose to matching that. By the time itcomes across our scales, we’ve got moremoney invested in the timber, countingthe increased cost of cutting it on our timbertracts and hauling it to our sawmilloperation. Then when the finished productleaves the mill, it is transported bytruck, train or ship. They all use dieselfuel. Our main concern is having a profitafter you pay the freight.”Truitt added, “You’ve got to keep loggersand truckers in business. We’re tryingto do everything we can here to bemore efficient.”Founded in 1999 by Rabun Beasley, thefirm’s owner and president, BeasleyForest Products Inc. has grown from itsoriginal 20-acre sawmill operation toinclude a large log yard with a sprinklersystem, an air-drying yard and warehous-38 Hardwoods Have Workability

Linwood Truitt is standing in front of the two new SII dry kilns that the company justrecently installed.This is the 7-foot McDonough band saw cutting a large log into lumber.This is a huge log that will soon be processed into lumber. Beasley’s new McDonoughband saw will cut up to a 50-inch thick log.A view of Beasley Forest Products’ air drying yard, which has a total capacity of 6 millionboard feet.es covering part of their 40 acres.Producing some 90 million board feetof lumber annually, Beasley is the secondlargest Hardwood grade sawmill in theUnited States. The company’s productline includes 4/4 Hardwood grade andcypress lumber, railroad ties, crane mats,pallet components, pallet lumber,Hardwood and cypress bark, chips andsawdust.Beasley saws and kiln dries SouthernHardwoods species such as Red andWhite Oak, Poplar, and Ash (4/4, FAS,No. 1 and 2 Common). Just last year, thefirm began re-manufacturing cypress tovarious patterns including v-joint, beadedceiling, siding and radius edge decking.All lumber at Beasley receives anti-staintreatment and end-coat paint to reducesplitting and checking.Key personnel at Beasley ForestProducts Inc. includes: Rabun Beasley,president and owner of the company;Darrell Beasley, vice president; LinwoodTruitt, grade lumber sales; Phil Clements,plant manager; Ricky Lilliott, maintenancesupervisor; Josephine Beasley,office manager; Zach Johnson, timberprocurement manager; and Lee Miles,pallet component sales.Beasley employs 180 people who operatetwo shifts during a five-day workweek.With 21 loggers and seven timber buyerson staff, Beasley Forest Productsdirectly controls and personally harvestsover 75 percent of the logs sawn in theirmill. The remaining 25 percent is purchasedfrom outside log suppliers. Thefirm also maintains a 15-acre log yardwith a sprinkler system to ensure consistentlog flow into the mill year round.The Hazlehurst, Ga., facility is strategicallylocated within five miles of threemajor rivers, the Oconee, Ocmulgee andAltamaha, and near other river systems,which gives Beasley access to an excellentsupply of Hardwood timber. Thecompany is located just 125 miles fromthree port cities — Savannah andBrunswick, Ga., and Jacksonville, Fla. —and offers container loading for export.With several trucking companies in thearea, Beasley can also guarantee promptdelivery of its lumber and other forestproducts to customers.For more information, contact BeasleyForest Products Inc. at 912-375-5174,visit www.beasleyforestproducts.com oremail bfp9541@bellsouth.net.•SEPTEMBER/2008 39

- Page 3: SEPTEMBER/2008 1

- Page 9: makes it easy for you to beITL Corp

- Page 12: Fifty years ago, tough grading, sta

- Page 16: The Leader in Log and Lumber Protec

- Page 20 and 21: Supplier news about sales, labor, p

- Page 22: News from suppliers about prices,tr

- Page 25 and 26: News about North American industria

- Page 27 and 28: Our kiln manager, Rick Rogers, hasd

- Page 29 and 30: PUTTING YOU FIRST.[ Bill Redman, vi

- Page 31 and 32: Our lumbermeasures up toyour highes

- Page 33 and 34: Character Grade Lumber for Characte

- Page 35 and 36: TICK. DOCK.ON TIME DELIVERY.Cole Ha

- Page 37 and 38: We at Bryant Church Hardwoods, Inc.

- Page 39: not be undertaken and the lumber bu

- Page 43 and 44: Kenneth Cox, plant manager, Salem F

- Page 45 and 46: tes 100th AnniversaryBY WAYNE MILLE

- Page 47 and 48: John Zirkel, lifetime honorary memb

- Page 49 and 50: LUMBER CO. INC.,., SuiteSuite 2300,

- Page 51 and 52: WHA Focuses OnGlobal MarketBY WAYNE

- Page 53 and 54: ‘Global Gathering’meetings in c

- Page 55 and 56: ts Draws ThousandsPHOTOS BY CHARLES

- Page 57 and 58: C.A. SPENCER PHOTOS - ContinuedAlai

- Page 59 and 60: WHA PHOTOS - ContinuedDoug and Cath

- Page 61 and 62: LSLA PHOTOS - ContinuedDave Rhodes,

- Page 63 and 64: PENN-YORK PHOTOS - Continued from p

- Page 65 and 66: PENN-YORK PHOTOS - ContinuedT&S Har

- Page 67 and 68: PACIFIC COAST -Continued from page

- Page 69 and 70: SALEM FRAME -Continuedstrengthens o

- Page 71 and 72: HINES - Continueddifferent yards to

- Page 73 and 74: AHEC UPDATE - ContinuedWashington,

- Page 75 and 76: SOUTHEAST TRENDS -Continued from pa

- Page 77 and 78: LAKE STATES TRENDS -Continuedupward

- Page 79 and 80: A brief sketch of the leading purch

- Page 81 and 82: SEARCHING FOR NEW BUYERS FOR YOUR L

- Page 83 and 84: An update covering thelatest news a

- Page 85 and 86: TRADE TALK - ContinuedDwight’s th

- Page 87 and 88: ONTARIO TRENDS - Continued217,800 u

- Page 89 and 90: OBITUARYRichard H. ElliottTraverse

- Page 91 and 92:

EQUIPMENTEQUIPMENT FOR SALENEW/USED

- Page 93 and 94:

PRIDE HARDWOOD, LLCP. O. Box 1387

- Page 95 and 96:

And We Think The World Of You Too!F