GC Catalog 2011 2012 - Gaston College

GC Catalog 2011 2012 - Gaston College

GC Catalog 2011 2012 - Gaston College

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

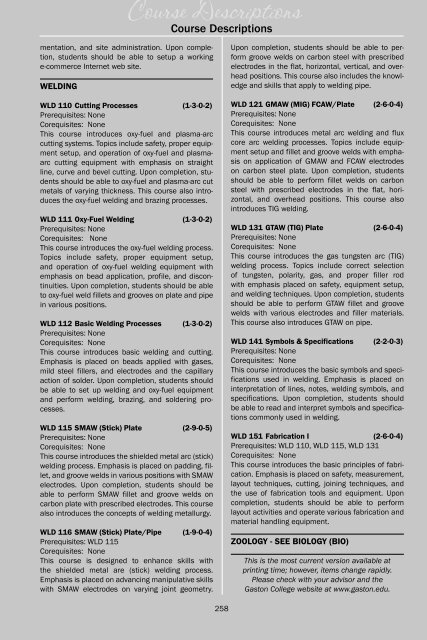

Course DescriptionsCourse Descriptionsmentation, and site administration. Upon completion,students should be able to setup a workinge-commerce Internet web site.WELDINGWLD 110 Cutting Processes (1-3-0-2)Prerequisites: NoneCorequisites: NoneThis course introduces oxy-fuel and plasma-arccutting systems. Topics include safety, proper equipmentsetup, and operation of oxy-fuel and plasmaarccutting equipment with emphasis on straightline, curve and bevel cutting. Upon completion, studentsshould be able to oxy-fuel and plasma-arc cutmetals of varying thickness. This course also introducesthe oxy-fuel welding and brazing processes.WLD 111 Oxy-Fuel Welding (1-3-0-2)Prerequisites: NoneCorequisites: NoneThis course introduces the oxy-fuel welding process.Topics include safety, proper equipment setup,and operation of oxy-fuel welding equipment withemphasis on bead application, profile, and discontinuities.Upon completion, students should be ableto oxy-fuel weld fillets and grooves on plate and pipein various positions.WLD 112 Basic Welding Processes (1-3-0-2)Prerequisites: NoneCorequisites: NoneThis course introduces basic welding and cutting.Emphasis is placed on beads applied with gases,mild steel fillers, and electrodes and the capillaryaction of solder. Upon completion, students shouldbe able to set up welding and oxy-fuel equipmentand perform welding, brazing, and soldering processes.WLD 115 SMAW (Stick) Plate (2-9-0-5)Prerequisites: NoneCorequisites: NoneThis course introduces the shielded metal arc (stick)welding process. Emphasis is placed on padding, fillet,and groove welds in various positions with SMAWelectrodes. Upon completion, students should beable to perform SMAW fillet and groove welds oncarbon plate with prescribed electrodes. This coursealso introduces the concepts of welding metallurgy.WLD 116 SMAW (Stick) Plate/Pipe (1-9-0-4)Prerequisites: WLD 115Corequisites: NoneThis course is designed to enhance skills withthe shielded metal are (stick) welding process.Emphasis is placed on advancing manipulative skillswith SMAW electrodes on varying joint geometry.Upon completion, students should be able to performgroove welds on carbon steel with prescribedelectrodes in the flat, horizontal, vertical, and overheadpositions. This course also includes the knowledgeand skills that apply to welding pipe.WLD 121 GMAW (MIG) FCAW/Plate (2-6-0-4)Prerequisites: NoneCorequisites: NoneThis course introduces metal arc welding and fluxcore arc welding processes. Topics include equipmentsetup and fillet and groove welds with emphasison application of GMAW and FCAW electrodeson carbon steel plate. Upon completion, studentsshould be able to perform fillet welds on carbonsteel with prescribed electrodes in the flat, horizontal,and overhead positions. This course alsointroduces TIG welding.WLD 131 GTAW (TIG) Plate (2-6-0-4)Prerequisites: NoneCorequisites: NoneThis course introduces the gas tungsten arc (TIG)welding process. Topics include correct selectionof tungsten, polarity, gas, and proper filler rodwith emphasis placed on safety, equipment setup,and welding techniques. Upon completion, studentsshould be able to perform GTAW fillet and groovewelds with various electrodes and filler materials.This course also introduces GTAW on pipe.WLD 141 Symbols & Specifications (2-2-0-3)Prerequisites: NoneCorequisites: NoneThis course introduces the basic symbols and specificationsused in welding. Emphasis is placed oninterpretation of lines, notes, welding symbols, andspecifications. Upon completion, students shouldbe able to read and interpret symbols and specificationscommonly used in welding.WLD 151 Fabrication I (2-6-0-4)Prerequisites: WLD 110, WLD 115, WLD 131Corequisites: NoneThis course introduces the basic principles of fabrication.Emphasis is placed on safety, measurement,layout techniques, cutting, joining techniques, andthe use of fabrication tools and equipment. Uponcompletion, students should be able to performlayout activities and operate various fabrication andmaterial handling equipment.ZOOLOGY - SEE BIOLOGY (BIO)This is the most current version available atprinting time; however, items change rapidly.Please check with your advisor and the<strong>Gaston</strong> <strong>College</strong> website at www.gaston.edu.258