- Page 1:

PROCEEDINGS OF THEINTERNATIONAL WOR

- Page 5 and 6:

ContentsPrefaceiiiPlenary TalksYaro

- Page 7 and 8:

ContentsviiFuh-Hwa Franklin Liu, Ch

- Page 9:

PLENARY TALKS

- Page 12 and 13:

4 Yaroslav D. Sergeyevto work with

- Page 15:

EXTENDED ABSTRACTS

- Page 18 and 19:

10 Bernardetta Addis and Sven Leyff

- Page 20 and 21:

12 Bernardetta Addis and Sven Leyff

- Page 22 and 23:

14 Bernardetta Addis and Sven Leyff

- Page 24 and 25:

16 Bernardetta Addis, Marco Locatel

- Page 26 and 27:

18 April K. Andreas and J. Cole Smi

- Page 28 and 29:

20 April K. Andreas and J. Cole Smi

- Page 30 and 31:

22 April K. Andreas and J. Cole Smi

- Page 32 and 33:

24 Charles Audet, Pierre Hansen, an

- Page 34 and 35:

26 Charles Audet, Pierre Hansen, an

- Page 36 and 37:

28 Charles Audet, Pierre Hansen, an

- Page 38 and 39:

30 János Balogh, József Békési,

- Page 40 and 41:

32 János Balogh, József Békési,

- Page 42 and 43:

34 János Balogh, József Békési,

- Page 44 and 45:

36 Balázs Bánhelyi, Tibor Csendes

- Page 47 and 48:

Proceedings of GO 2005, pp. 39 - 45

- Page 49 and 50:

MGA Pruning Technique 41Figure 1. A

- Page 51 and 52:

MGA Pruning Technique 43O(n) = k 2

- Page 53:

MGA Pruning Technique 45one), while

- Page 56 and 57:

48 Edson Tadeu Bez, Mirian Buss Gon

- Page 58 and 59:

50 Edson Tadeu Bez, Mirian Buss Gon

- Page 60 and 61:

52 Edson Tadeu Bez, Mirian Buss Gon

- Page 62 and 63:

54 R. Blanquero, E. Carrizosa, E. C

- Page 64 and 65:

56 R. Blanquero, E. Carrizosa, E. C

- Page 66 and 67:

58 Sándor Bozókiwhere for any i,

- Page 68 and 69:

60 Sándor Bozóki[6] Budescu, D.V.

- Page 70 and 71:

62 Emilio Carrizosa, José Gordillo

- Page 72 and 73:

64 Emilio Carrizosa, José Gordillo

- Page 75 and 76:

Proceedings of GO 2005, pp. 67 - 69

- Page 77:

Globally optimal prototypes 69Refer

- Page 80 and 81:

72 Leocadio G. Casado, Eligius M.T.

- Page 82 and 83:

874 Leocadio G. Casado, Eligius M.T

- Page 84 and 85:

76 Leocadio G. Casado, Eligius M.T.

- Page 86 and 87:

78 András Erik Csallner, Tibor Cse

- Page 88 and 89:

80 András Erik Csallner, Tibor Cse

- Page 90 and 91:

82 Tibor Csendes, Balázs Bánhelyi

- Page 92 and 93:

84 Tibor Csendes, Balázs Bánhelyi

- Page 94 and 95:

86 Bernd DachwaldFor spacecraft wit

- Page 96 and 97:

88 Bernd Dachwaldcurrent target sta

- Page 98 and 99:

90 Bernd Dachwaldreference launch d

- Page 100 and 101:

92 Mirjam Dür and Chris TofallisMo

- Page 102 and 103:

94 Mirjam Dür and Chris Tofallis2.

- Page 104 and 105:

96 Mirjam Dür and Chris Tofallis[3

- Page 106 and 107:

98 José Fernández and Boglárka T

- Page 108 and 109:

100 José Fernández and Boglárka

- Page 110 and 111:

102 José Fernández and Boglárka

- Page 112 and 113:

104 Erika R. Frits, Ali Baharev, Zo

- Page 114 and 115:

106 Erika R. Frits, Ali Baharev, Zo

- Page 116 and 117:

108 Erika R. Frits, Ali Baharev, Zo

- Page 118 and 119:

110 Juergen Garloff and Andrew P. S

- Page 120 and 121:

112 Juergen Garloff and Andrew P. S

- Page 123 and 124:

Proceedings of GO 2005, pp. 115 - 1

- Page 125 and 126:

Global multiobjective optimization

- Page 127 and 128:

Global multiobjective optimization

- Page 129 and 130:

Proceedings of GO 2005, pp. 121 - 1

- Page 131 and 132:

Conditions for ε-Pareto Solutions

- Page 133:

Conditions for ε-Pareto Solutions

- Page 136 and 137:

128 Eligius M.T. Hendrix1.1 Effecti

- Page 138 and 139:

130 Eligius M.T. Hendrix4h(x)3.532.

- Page 140 and 141:

132 Eligius M.T. Hendrixneighbourho

- Page 142 and 143:

134 Kenneth Holmströmcomputed by R

- Page 144 and 145:

136 Kenneth Holmströmα(x) =∑i=1

- Page 146 and 147:

138 Kenneth HolmströmGL-step Phase

- Page 148 and 149:

140 Kenneth Holmströmsurrogate mod

- Page 150 and 151:

142 Dario Izzo and Mihály Csaba Ma

- Page 152 and 153:

144 Dario Izzo and Mihály Csaba Ma

- Page 154 and 155:

146 Dario Izzo and Mihály Csaba Ma

- Page 156 and 157:

148 Leo Liberti and Milan DražićV

- Page 158 and 159:

150 Leo Liberti and Milan Dražićs

- Page 161 and 162:

Proceedings of GO 2005, pp. 153 - 1

- Page 163 and 164:

Set-covering based p-center problem

- Page 165 and 166:

Set-covering based p-center problem

- Page 167 and 168:

Proceedings of GO 2005, pp. 159 - 1

- Page 169 and 170:

On the Solution of Interplanetary T

- Page 171 and 172:

On the Solution of Interplanetary T

- Page 173 and 174: Proceedings of GO 2005, pp. 165 - 1

- Page 175 and 176: Parametrical approach for studying

- Page 177 and 178: Parametrical approach for studying

- Page 179 and 180: Proceedings of GO 2005, pp. 171 - 1

- Page 181 and 182: An Interval Branch-and-Bound Algori

- Page 183 and 184: An Interval Branch-and-Bound Algori

- Page 185 and 186: Proceedings of GO 2005, pp. 177 - 1

- Page 187 and 188: A New approach to the Studyof the S

- Page 189: A New approach to the Studyof the S

- Page 192 and 193: 184 Katharine M. Mullen, Mikas Veng

- Page 194 and 195: 186 Katharine M. Mullen, Mikas Veng

- Page 196 and 197: 188 Katharine M. Mullen, Mikas Veng

- Page 198 and 199: 190 Niels J. Olieman and Eligius M.

- Page 200 and 201: 192 Niels J. Olieman and Eligius M.

- Page 202 and 203: 194 Niels J. Olieman and Eligius M.

- Page 204 and 205: 196 Andrey V. Orlovwhere A is (m 1

- Page 206 and 207: 198 Andrey V. OrlovStep 4. Beginnin

- Page 208 and 209: 200 Blas Pelegrín, Pascual Fernán

- Page 210 and 211: 202 Blas Pelegrín, Pascual Fernán

- Page 212 and 213: 204 Blas Pelegrín, Pascual Fernán

- Page 214 and 215: 206 Blas Pelegrín, Pascual Fernán

- Page 216 and 217: 208 Deolinda M. L. D. Rasteiro and

- Page 218 and 219: 210 Deolinda M. L. D. Rasteiro and

- Page 220 and 221: 212 Deolinda M. L. D. Rasteiro and

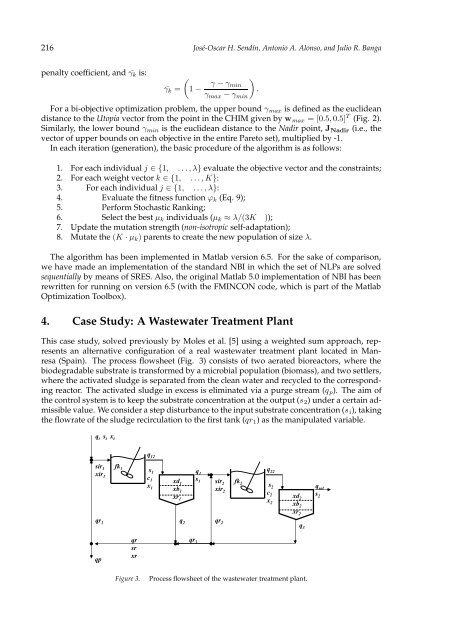

- Page 222 and 223: 214 José-Oscar H. Sendín, Antonio

- Page 226 and 227: 218 José-Oscar H. Sendín, Antonio

- Page 228 and 229: 220 Ya. D. Sergeyev and D. E. Kvaso

- Page 230 and 231: 222 Ya. D. Sergeyev and D. E. Kvaso

- Page 232 and 233: 224 Ya. D. Sergeyev and D. E. Kvaso

- Page 234 and 235: 226 J. Cole Smith, Fransisca Sudarg

- Page 236 and 237: 228 J. Cole Smith, Fransisca Sudarg

- Page 238 and 239: 230 J. Cole Smith, Fransisca Sudarg

- Page 240 and 241: 232 Fazil O. Sonmezcost of a config

- Page 242 and 243: 234 Fazil O. Sonmezhere f h is the

- Page 244 and 245: 236 Fazil O. SonmezThe optimal shap

- Page 246 and 247: 238 Alexander S. StrekalovskyDevelo

- Page 249 and 250: Proceedings of GO 2005, pp. 241 - 2

- Page 251 and 252: PSfrag replacementsPruning a box fr

- Page 253 and 254: Pruning a box from Baumann point in

- Page 255 and 256: Proceedings of GO 2005, pp. 247 - 2

- Page 257 and 258: A Hybrid Multi-Agent Collaborative

- Page 259 and 260: A Hybrid Multi-Agent Collaborative

- Page 261 and 262: Proceedings of GO 2005, pp. 253 - 2

- Page 263: Improved lower bounds for optimizat

- Page 266 and 267: 258 Graham R. Wood, Duangdaw Sirisa

- Page 268 and 269: 260 Graham R. Wood, Duangdaw Sirisa

- Page 270 and 271: 262 Graham R. Wood, Duangdaw Sirisa

- Page 272 and 273: 264 Yinfeng Xu and Wenqiang Daiopti

- Page 274 and 275:

266 Yinfeng Xu and Wenqiang DaiThe

- Page 277 and 278:

Author IndexAddis, BernardettaDipar

- Page 279:

Author Index 271Nasuto, S.J.Departm