View - Universidad de AlmerÃa

View - Universidad de AlmerÃa

View - Universidad de AlmerÃa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

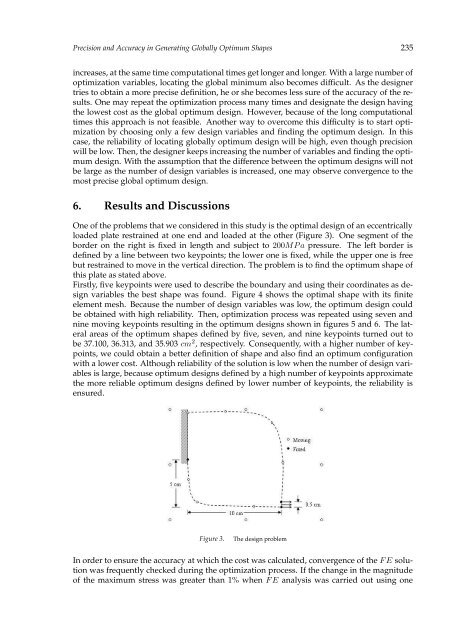

Precision and Accuracy in Generating Globally Optimum Shapes 235increases, at the same time computational times get longer and longer. With a large number ofoptimization variables, locating the global minimum also becomes difficult. As the <strong>de</strong>signertries to obtain a more precise <strong>de</strong>finition, he or she becomes less sure of the accuracy of the results.One may repeat the optimization process many times and <strong>de</strong>signate the <strong>de</strong>sign havingthe lowest cost as the global optimum <strong>de</strong>sign. However, because of the long computationaltimes this approach is not feasible. Another way to overcome this difficulty is to start optimizationby choosing only a few <strong>de</strong>sign variables and finding the optimum <strong>de</strong>sign. In thiscase, the reliability of locating globally optimum <strong>de</strong>sign will be high, even though precisionwill be low. Then, the <strong>de</strong>signer keeps increasing the number of variables and finding the optimum<strong>de</strong>sign. With the assumption that the difference between the optimum <strong>de</strong>signs will notbe large as the number of <strong>de</strong>sign variables is increased, one may observe convergence to themost precise global optimum <strong>de</strong>sign.6. Results and DiscussionsOne of the problems that we consi<strong>de</strong>red in this study is the optimal <strong>de</strong>sign of an eccentricallyloa<strong>de</strong>d plate restrained at one end and loa<strong>de</strong>d at the other (Figure 3). One segment of thebor<strong>de</strong>r on the right is fixed in length and subject to 200MP a pressure. The left bor<strong>de</strong>r is<strong>de</strong>fined by a line between two keypoints; the lower one is fixed, while the upper one is freebut restrained to move in the vertical direction. The problem is to find the optimum shape ofthis plate as stated above.Firstly, five keypoints were used to <strong>de</strong>scribe the boundary and using their coordinates as <strong>de</strong>signvariables the best shape was found. Figure 4 shows the optimal shape with its finiteelement mesh. Because the number of <strong>de</strong>sign variables was low, the optimum <strong>de</strong>sign couldbe obtained with high reliability. Then, optimization process was repeated using seven andnine moving keypoints resulting in the optimum <strong>de</strong>signs shown in figures 5 and 6. The lateralareas of the optimum shapes <strong>de</strong>fined by five, seven, and nine keypoints turned out tobe 37.100, 36.313, and 35.903 cm 2 , respectively. Consequently, with a higher number of keypoints,we could obtain a better <strong>de</strong>finition of shape and also find an optimum configurationwith a lower cost. Although reliability of the solution is low when the number of <strong>de</strong>sign variablesis large, because optimum <strong>de</strong>signs <strong>de</strong>fined by a high number of keypoints approximatethe more reliable optimum <strong>de</strong>signs <strong>de</strong>fined by lower number of keypoints, the reliability isensured.Figure 3.The <strong>de</strong>sign problemIn or<strong>de</strong>r to ensure the accuracy at which the cost was calculated, convergence of the F E solutionwas frequently checked during the optimization process. If the change in the magnitu<strong>de</strong>of the maximum stress was greater than 1% when F E analysis was carried out using one