Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

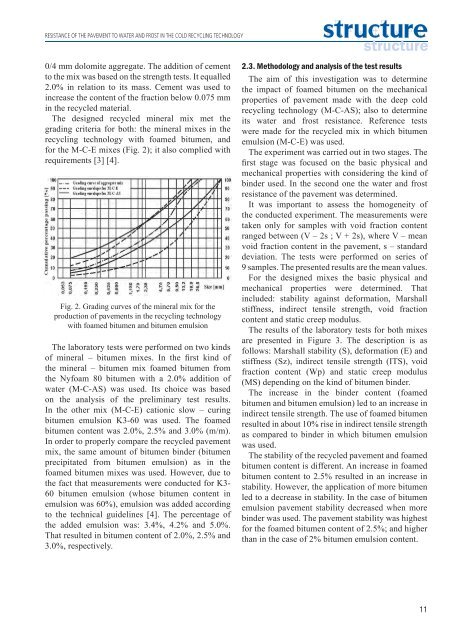

RESISTANCE OF THE PAVEMENT TO WATER AND FROST IN THE COLD RECYCLING TECHNOLOGY0/4 mm dolomite aggregate. The addition of cementto the mix was based on the strength tests. It equalled2.0% in relation to its mass. Cement was used toincrease the content of the fraction below 0.075 mmin the recycled material.The designed recycled mineral mix met thegrading criteria for both: the mineral mixes in therecycling technology with foamed bitumen, <strong>and</strong>for the M-C-E mixes (Fig. 2); it also complied withrequirements [3] [4].Fig. 2. Grading curves of the mineral mix for theproduction of pavements in the recycling technologywith foamed bitumen <strong>and</strong> bitumen emulsionThe laboratory tests were performed on two kindsof mineral – bitumen mixes. In the first kind ofthe mineral – bitumen mix foamed bitumen fromthe Nyfoam 80 bitumen with a 2.0% addition ofwater (M-C-AS) was used. Its choice was basedon the analysis of the preliminary test results.In the other mix (M-C-E) cationic slow – curingbitumen emulsion K3-60 was used. The foamedbitumen content was 2.0%, 2.5% <strong>and</strong> 3.0% (m/m).In order to properly compare the recycled pavementmix, the same amount of bitumen binder (bitumenprecipitated from bitumen emulsion) as in thefoamed bitumen mixes was used. However, due tothe fact that measurements were conducted for K3-60 bitumen emulsion (whose bitumen content inemulsion was 60%), emulsion was added accordingto the technical guidelines [4]. The percentage ofthe added emulsion was: 3.4%, 4.2% <strong>and</strong> 5.0%.That resulted in bitumen content of 2.0%, 2.5% <strong>and</strong>3.0%, respectively.2.3. Methodology <strong>and</strong> analysis of the test resultsThe aim of this investigation was to determinethe impact of foamed bitumen on the mechanicalproperties of pavement made with the deep coldrecycling technology (M-C-AS); also to determineits water <strong>and</strong> frost resistance. Reference testswere made for the recycled mix in which bitumenemulsion (M-C-E) was used.The experiment was carried out in two stages. Thefirst stage was focused on the basic physical <strong>and</strong>mechanical properties with considering the kind ofbinder used. In the second one the water <strong>and</strong> frostresistance of the pavement was determined.It was important to assess the homogeneity ofthe conducted experiment. The measurements weretaken only for samples with void fraction contentranged between (V – 2s ; V + 2s), where V – meanvoid fraction content in the pavement, s – st<strong>and</strong>arddeviation. The tests were performed on series of9 samples. The presented results are the mean values.For the designed mixes the basic physical <strong>and</strong>mechanical properties were determined. Thatincluded: stability against deformation, Marshallstiffness, indirect tensile strength, void fractioncontent <strong>and</strong> static creep modulus.The results of the laboratory tests for both mixesare presented in Figure 3. The description is asfollows: Marshall stability (S), deformation (E) <strong>and</strong>stiffness (Sz), indirect tensile strength (ITS), voidfraction content (Wp) <strong>and</strong> static creep modulus(MS) depending on the kind of bitumen binder.The increase in the binder content (foamedbitumen <strong>and</strong> bitumen emulsion) led to an increase inindirect tensile strength. The use of foamed bitumenresulted in about 10% rise in indirect tensile strengthas compared to binder in which bitumen emulsionwas used.The stability of the recycled pavement <strong>and</strong> foamedbitumen content is different. An increase in foamedbitumen content to 2.5% resulted in an increase instability. However, the application of more bitumenled to a decrease in stability. In the case of bitumenemulsion pavement stability decreased when morebinder was used. The pavement stability was highestfor the foamed bitumen content of 2.5%; <strong>and</strong> higherthan in the case of 2% bitumen emulsion content.11