Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

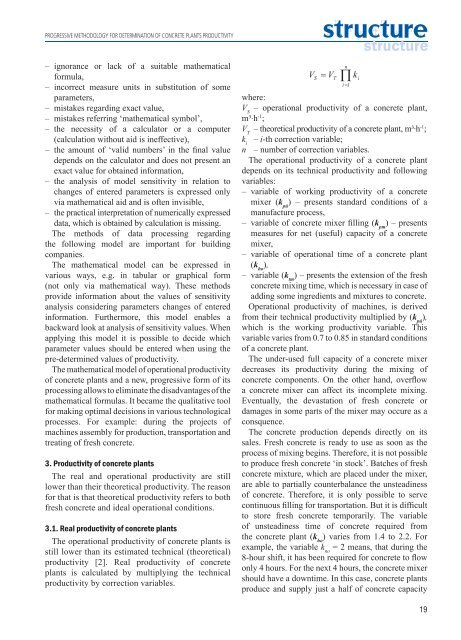

PROGRESSIVE METHODOLOGY FOR DETERMINATION OF CONCRETE PLANTS PRODUCTIVITY– ignorance or lack of a suitable mathematicalformula,– incorrect measure units in substitution of someparameters,– mistakes regarding exact value,– mistakes referring ‘mathematical symbol’,– the necessity of a calculator or a computer(calculation without aid is ineffective),– the amount of ‘valid numbers’ in the final valuedepends on the calculator <strong>and</strong> does not present anexact value for obtained information,– the analysis of model sensitivity in relation tochanges of entered parameters is expressed onlyvia mathematical aid <strong>and</strong> is often invisible,– the practical interpretation of <strong>numer</strong>ically expresseddata, which is obtained by calculation is missing.The methods of data processing regardingthe following model are important for buildingcompanies.The mathematical model can be expressed invarious ways, e.g. in tabular or graphical form(not only via mathematical way). These methodsprovide information about the values of sensitivityanalysis considering parameters changes of enteredinformation. Furthermore, this model enables abackward look at analysis of sensitivity values. Whenapplying this model it is possible to decide whichparameter values should be entered when using thepre-determined values of productivity.The mathematical model of operational productivityof concrete plants <strong>and</strong> a new, progressive form of itsprocessing allows to eliminate the disadvantages of themathematical formulas. It became the qualitative toolfor making optimal decisions in various technologicalprocesses. For example: during the projects ofmachines assembly for production, transportation <strong>and</strong>treating of fresh concrete.3. Productivity of concrete plantsThe real <strong>and</strong> operational productivity are stilllower than their theoretical productivity. The reasonfor that is that theoretical productivity refers to bothfresh concrete <strong>and</strong> ideal operational conditions.3.1. Real productivity of concrete plantsThe operational productivity of concrete plants isstill lower than its estimated technical (theoretical)productivity [2]. Real productivity of concreteplants is calculated by multiplying the technicalproductivity by correction variables.where:V S– operational productivity of a concrete plant,m³ . h -1 ;V T– theoretical productivity of a concrete plant, m³ . h -1 ;k i– i-th correction variable;n – number of correction variables.The operational productivity of a concrete plantdepends on its technical productivity <strong>and</strong> followingvariables:– variable of working productivity of a concretemixer (k pú) – presents st<strong>and</strong>ard conditions of amanufacture process,– variable of concrete mixer filling (k pm) – presentsmeasures for net (useful) capacity of a concretemixer,– variable of operational time of a concrete plant(k ho),– variable (k tm) – presents the extension of the freshconcrete mixing time, which is necessary in case ofadding some ingredients <strong>and</strong> mixtures to concrete.Operational productivity of machines, is derivedfrom their technical productivity multiplied by (k pú),which is the working productivity variable. Thisvariable varies from 0.7 to 0.85 in st<strong>and</strong>ard conditionsof a concrete plant.The under-used full capacity of a concrete mixerdecreases its productivity during the mixing ofconcrete components. On the other h<strong>and</strong>, overflowa concrete mixer can affect its incomplete mixing.Eventually, the devastation of fresh concrete ordamages in some parts of the mixer may occure as aconsquence.The concrete production depends directly on itssales. Fresh concrete is ready to use as soon as theprocess of mixing begins. Therefore, it is not possibleto produce fresh concrete ‘in stock’. Batches of freshconcrete mixture, which are placed under the mixer,are able to partially counterbalance the unsteadinessof concrete. Therefore, it is only possible to servecontinuous filling for transportation. But it is difficultto store fresh concrete temporarily. The variableof unsteadiness time of concrete required fromthe concrete plant (k ho) varies from 1.4 to 2.2. Forexample, the variable k no= 2 means, that during the8-hour shift, it has been required for concrete to flowonly 4 hours. For the next 4 hours, the concrete mixershould have a downtime. In this case, concrete plantsproduce <strong>and</strong> supply just a half of concrete capacity19