Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

Pobierz pełny numer 1/2010 S&E - Structure and Environment - Kielce

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

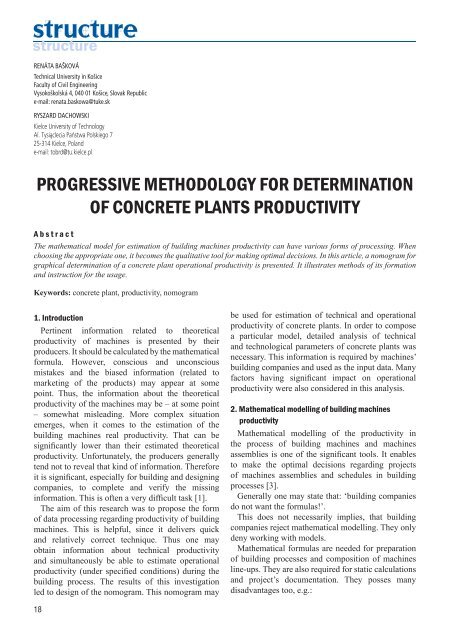

RENÁTA BAŠKOVÁTechnical University in KošiceFaculty of Civil EngineeringVysokoškolská 4, 040 01 Košice, Slovak Republice-mail: renata.baskowa@tuke.skRYSZARD DACHOWSKI<strong>Kielce</strong> University of TechnologyAl. Tysiąclecia Państwa Polskiego 725-314 <strong>Kielce</strong>, Pol<strong>and</strong>e-mail: tobrd@tu.kielce.plPROGRESSIVE METHODOLOGY FOR DETERMINATIONOF CONCRETE PLANTS PRODUCTIVITYA b s t r a c tThe mathematical model for estimation of building machines productivity can have various forms of processing. Whenchoosing the appropriate one, it becomes the qualitative tool for making optimal decisions. In this article, a nomogram forgraphical determination of a concrete plant operational productivity is presented. It illustrates methods of its formation<strong>and</strong> instruction for the usage.Keywords: concrete plant, productivity, nomogram1. IntroductionPertinent information related to theoreticalproductivity of machines is presented by theirproducers. It should be calculated by the mathematicalformula. However, conscious <strong>and</strong> unconsciousmistakes <strong>and</strong> the biased information (related tomarketing of the products) may appear at somepoint. Thus, the information about the theoreticalproductivity of the machines may be – at some point– somewhat misleading. More complex situationemerges, when it comes to the estimation of thebuilding machines real productivity. That can besignificantly lower than their estimated theoreticalproductivity. Unfortunately, the producers generallytend not to reveal that kind of information. Thereforeit is significant, especially for building <strong>and</strong> designingcompanies, to complete <strong>and</strong> verify the missinginformation. This is often a very difficult task [1].The aim of this research was to propose the formof data processing regarding productivity of buildingmachines. This is helpful, since it delivers quick<strong>and</strong> relatively correct technique. Thus one mayobtain information about technical productivity<strong>and</strong> simultaneously be able to estimate operationalproductivity (under specified conditions) during thebuilding process. The results of this investigationled to design of the nomogram. This nomogram maybe used for estimation of technical <strong>and</strong> operationalproductivity of concrete plants. In order to composea particular model, detailed analysis of technical<strong>and</strong> technological parameters of concrete plants wasnecessary. This information is required by machines’building companies <strong>and</strong> used as the input data. Manyfactors having significant impact on operationalproductivity were also considered in this analysis.2. Mathematical modelling of building machinesproductivityMathematical modelling of the productivity inthe process of building machines <strong>and</strong> machinesassemblies is one of the significant tools. It enablesto make the optimal decisions regarding projectsof machines assemblies <strong>and</strong> schedules in buildingprocesses [3].Generally one may state that: ‘building companiesdo not want the formulas!’.This does not necessarily implies, that buildingcompanies reject mathematical modelling. They onlydeny working with models.Mathematical formulas are needed for preparationof building processes <strong>and</strong> composition of machinesline-ups. They are also required for static calculations<strong>and</strong> project’s documentation. They posses manydisadvantages too, e.g.:18