- Page 1 and 2: Mitutoyo Precision Measuring Machin

- Page 3 and 4: One number to serve you better:Toll

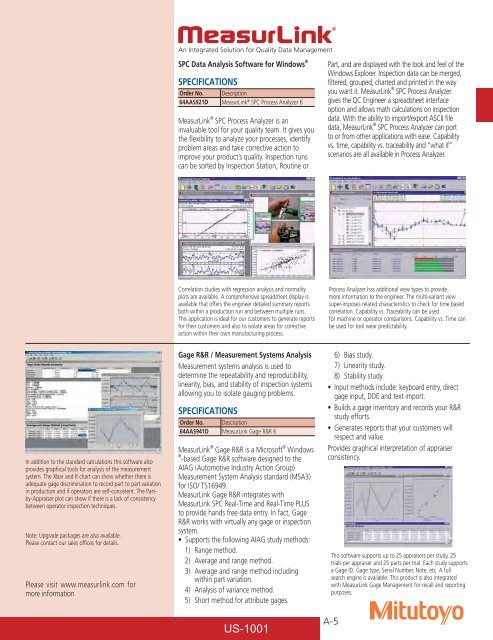

- Page 5 and 6: www.mitutoyo.comThe new US-1001 Cat

- Page 7 and 8: Calibration ServicesMitutoyo Americ

- Page 9 and 10: ■ Sales■ Research andDevelopmen

- Page 11 and 12: Traceability Mitutoyo North America

- Page 13 and 14: CanadaMexicoUKNetherlandGermanySwit

- Page 15 and 16: Certificate of JCSS accredited labo

- Page 17 and 18: ASmall Tool Instruments andData Man

- Page 19: Versatile. Powerful. Easy-to-Use. T

- Page 23 and 24: The Pocket ML combined chartis cust

- Page 25 and 26: U-WAVEMeasurement Data Wireless Com

- Page 27 and 28: Multiplexers - MIG-2B, MIG-4ASERIES

- Page 29 and 30: DP-1VRSERIES 264 — Digimatic Mini

- Page 31 and 32: BSmall Tool Instruments andData Man

- Page 33 and 34: SPECIFICATIONSMetricRange Resolutio

- Page 35 and 36: QuantuMikeSERIES 293 — Coolant Pr

- Page 37 and 38: QuickmikeSERIES 293 — IP-54 ABSOL

- Page 39 and 40: Ratchet Thimble MicrometerSERIES 10

- Page 41 and 42: Outside MicrometersSERIES 103Techni

- Page 43 and 44: Outside MicrometersSERIES 103 — I

- Page 45 and 46: Outside MicrometersSERIES 340, 104

- Page 47 and 48: Technical DataAccuracy: Refer to th

- Page 49 and 50: Spline MicrometersSERIES 331, 111Te

- Page 51 and 52: DIMENSIONS Unit: mmRange L a b c

- Page 53 and 54: SPECIFICATIONSMetricRange Graduatio

- Page 55 and 56: Pana MicrometersSERIES 116 — Inte

- Page 57 and 58: Tube MicrometersSERIES 395, 295, 11

- Page 59 and 60: Sheet Metal MicrometersSERIES 389,

- Page 61 and 62: Disk MicrometersSERIES 323, 223, 12

- Page 63 and 64: Technical DataAccuracy: Refer to th

- Page 65 and 66: Gear Tooth MicrometersSERIES 324, 1

- Page 67 and 68: Screw Thread MicrometersSERIES 326,

- Page 69 and 70: Can Seam MicrometersSERIES 147Techn

- Page 71 and 72:

Digit Outside MicrometersSERIES 193

- Page 73 and 74:

Technical DataDial reading: .00005

- Page 75 and 76:

Groove MicrometersSERIES 146FEATURE

- Page 77 and 78:

Micrometer StandsSERIES 156These st

- Page 79 and 80:

Technical Data Parallelism Check

- Page 81 and 82:

Standards for Screw Thread Micromet

- Page 83 and 84:

Tool KitsThis Tool Kit contains the

- Page 85 and 86:

Micrometer Head Selection GuideVari

- Page 87 and 88:

Digimatic Micrometer HeadsSERIES 35

- Page 89 and 90:

Micrometer HeadsSERIES 148 — Fine

- Page 91 and 92:

ø14Micrometer HeadsSERIES 148 —

- Page 93 and 94:

Micrometer HeadsSERIES 148 — Comm

- Page 95 and 96:

150-801150-191Technical DataGraduat

- Page 97 and 98:

Micrometer HeadsSERIES 153 — Non-

- Page 99 and 100:

Micrometer HeadsSERIES 110 — Diff

- Page 103 and 104:

Micrometer HeadsSERIES 250 — with

- Page 105 and 106:

Fixtures for Micrometer HeadsFEATUR

- Page 107 and 108:

CSmall Tool Instruments andData Man

- Page 109 and 110:

SPECIFICATIONSMetricIndividualRange

- Page 111 and 112:

SPECIFICATIONSMetricIndividualRange

- Page 113 and 114:

ConeHT (Type II)ContactpointCarbide

- Page 115 and 116:

Interchangeable Contact Head Set568

- Page 117 and 118:

Tubular Inside MicrometersSERIES 13

- Page 119 and 120:

Inside MicrometersSERIES 141 — In

- Page 121 and 122:

Tubular Inside MicrometersSERIES 13

- Page 123 and 124:

Tubular Inside MicrometersSERIES 14

- Page 125 and 126:

Inside Micro CheckerSERIES 515FEATU

- Page 127 and 128:

Bore GagesSERIES 511—Standard Typ

- Page 129 and 130:

Bore GagesSERIES 511 — Short Leg

- Page 131 and 132:

Bore GagesSERIES 511 — with Micro

- Page 133 and 134:

ABSOLUTE Digimatic Bore GageSERIES

- Page 135 and 136:

Standard Accessories64AAA012: 21BZA

- Page 137 and 138:

Ceramic Setting RingSERIES 177 —

- Page 139 and 140:

DSmall Tool Instruments andData Man

- Page 141 and 142:

ABSOLUTE Solar CaliperSERIES 500

- Page 143 and 144:

Air leakage detection system used f

- Page 145 and 146:

500-506-10500-502-10500-501-10 500-

- Page 147 and 148:

"Quadri" (4-way) Measurement1. Outs

- Page 149 and 150:

“Quadri” (4 way) MeasurementMea

- Page 151 and 152:

Vernier CaliperSERIES 532 — with

- Page 153 and 154:

ABSOLUTE Digimatic & Vernier Calipe

- Page 155 and 156:

ABSOLUTE Digimatic & Vernier Calipe

- Page 157 and 158:

552-151-10Ceramic jawsCenterline at

- Page 159 and 160:

ABSOLUTE Back-Jaw Centerline Calipe

- Page 161 and 162:

Offset Centerline CaliperSERIES 573

- Page 163 and 164:

Blade Type CaliperSERIES 573, 536

- Page 165 and 166:

Tube Thickness CaliperSERIES 573, 5

- Page 167 and 168:

Scribing CaliperSERIES 573, 536 —

- Page 169 and 170:

DIMENSIONS AND MASSUnit: mmKnife-ed

- Page 171 and 172:

Center Line GageOptional Accessorie

- Page 173 and 174:

Digimatic Height GageSERIES 192 —

- Page 175 and 176:

ABSOLUTE Digimatic Height GageSERIE

- Page 177 and 178:

Technical Data Repeatability: .0001

- Page 179 and 180:

Vernier Height GageSERIES 506 — L

- Page 181 and 182:

CERA Caliper CheckerSERIES 515FEATU

- Page 183 and 184:

Optional Accessories12AAC072: q Dep

- Page 185 and 186:

Optional Accessories12AAC072: Depth

- Page 187 and 188:

Depth MicrometerSERIES 128Technical

- Page 189 and 190:

Vernier Depth GageSERIES 527FEATURE

- Page 191 and 192:

Technical DataDial reading: .001”

- Page 193 and 194:

DIMENSIONSUnit: mm(10) (114)12ø8ø

- Page 195 and 196:

ESmall Tool Instruments andData Man

- Page 197 and 198:

Grade and ApplicationRefer to the f

- Page 199 and 200:

Metric Rectangular Gage Block SetSE

- Page 201 and 202:

Inch Rectangular Gage Block SetSERI

- Page 203 and 204:

Individual Metric RectangularGage B

- Page 205 and 206:

Suffix Number for Selecting Standar

- Page 207 and 208:

Rectangular Gage Block AccessoriesS

- Page 209 and 210:

Rectangular Gage Block AccessoriesH

- Page 211 and 212:

Provided with Inspection Certificat

- Page 213 and 214:

Suffix Number for Selecting Standar

- Page 215 and 216:

Half round jaw:Used to measure an i

- Page 217 and 218:

Step MasterSERIES 516FEATURESStep m

- Page 219 and 220:

Technical DataGraduation: .00001" o

- Page 221 and 222:

Technical DataGraduation: .00001"Co

- Page 223 and 224:

Technical DataMeasuring range (R):

- Page 225 and 226:

Snap Gage CheckerSERIES 515Technica

- Page 227 and 228:

Technical DataAccuracy (at 20°C):

- Page 229 and 230:

Knife Edge Straight EdgeSERIES 528T

- Page 231 and 232:

Combination Square SetSERIES 180Tec

- Page 233 and 234:

Steel RulesSERIES 182FEATURES• Cl

- Page 235 and 236:

Thickness GagesSERIES 950, 184Techn

- Page 237 and 238:

Universal Bevel ProtractorSERIES 18

- Page 239 and 240:

Depth Gage, Adjustable AngleSERIES

- Page 241 and 242:

Angle BlocksSERIES 981SPECIFICATION

- Page 243 and 244:

Radius Gages-SetsSERIES 186FEATURES

- Page 245 and 246:

Center GageSERIES 950FEATURES• Ha

- Page 247 and 248:

985-144985-143Center FinderSERIES 9

- Page 249 and 250:

Bench ComparatorSERIES 162Technical

- Page 251 and 252:

Digital Hand TachometersSERIES 982F

- Page 253 and 254:

Granite Surface Plate AccessoriesSE

- Page 255 and 256:

SIZEHInchSize50 lbs.-Load / sq. ft.

- Page 257 and 258:

FSmall Tool Instruments andData Man

- Page 259 and 260:

ABSOLUTE Digimatic Indicator ID-USE

- Page 261 and 262:

330° Rotary displayThe display can

- Page 263 and 264:

ABSOLUTE Digimatic Indicator ID-CSE

- Page 265 and 266:

ABSOLUTE Digimatic Indicator ID-CSE

- Page 267 and 268:

ABSOLUTE Digimatic Indicator ID-FSE

- Page 269 and 270:

EC CounterSERIES 542 — Low-cost,

- Page 271 and 272:

Dial IndicatorsSERIES 0 - Compact t

- Page 273 and 274:

Dial IndicatorsSERIES 11040S1013S10

- Page 275 and 276:

Dial IndicatorsSERIES 2 — Standar

- Page 277 and 278:

Special Dial IndicatorsSERIES 2Adju

- Page 279 and 280:

ABBDial IndicatorsSERIES 2 — Stan

- Page 281 and 282:

Dial IndicatorsSERIES 2 — Metric

- Page 283 and 284:

Dial IndicatorsSERIES 3 — Large D

- Page 285 and 286:

Dial IndicatorsSERIES 4 — Large D

- Page 287 and 288:

Back Plunger Type Dial IndicatorsSE

- Page 289 and 290:

25ϒContact PointsOptional Accessor

- Page 291 and 292:

Spindle Lifting Lever and CableOpti

- Page 293 and 294:

Dial Indicator Repair Tool KitOptio

- Page 295 and 296:

Dial Test IndicatorsSERIES 513 —

- Page 297 and 298:

Dial Test IndicatorsSERIES 513 —

- Page 299 and 300:

Pocket Type Dial Test IndicatorsSER

- Page 301 and 302:

Set Configuration: MetricFull setCo

- Page 303 and 304:

Technical DataMeasuring Range: 100m

- Page 305 and 306:

Thickness GagesSERIES 547, 7Technic

- Page 307 and 308:

Thickness GagesSERIES 547, 7Tube th

- Page 309 and 310:

Technical DataAccuracy: Refer to th

- Page 311 and 312:

991212Digimatic Caliper GagesSERIES

- Page 313 and 314:

Type of Contact PointsSUpper / Lowe

- Page 315 and 316:

ApplicationMeasuring contact force

- Page 317 and 318:

Dial/Digimatic Indicator & Magnetic

- Page 319 and 320:

519-109ETransfer StandSERIES 519The

- Page 321 and 322:

GSensor SystemsLinear GagesLaser Sc

- Page 323 and 324:

Linear GageDisplay50mm 100mm Single

- Page 325 and 326:

Linear Gage LGKSERIES 542 — 0.1μ

- Page 327 and 328:

10.6Linear Gage LGF-Z with Origin P

- Page 329 and 330:

Linear Gage LGSSERIES 575 — .0005

- Page 331 and 332:

Technical Data Stem: ø15mm Op

- Page 333 and 334:

EC CounterSERIES 542 — Assembly T

- Page 335 and 336:

EG CounterSERIES 542 — Assembly T

- Page 337 and 338:

FunctionOutputExternal ControlRS Li

- Page 339 and 340:

Litematic and Litematic HeadSERIES

- Page 341 and 342:

Laser Scan Micrometer Selection Gui

- Page 343 and 344:

Laser Scan Micrometer LSM-9506SERIE

- Page 345 and 346:

Laser Scan Micrometer LSM-500SSERIE

- Page 347 and 348:

Laser Scan Micrometer LSM-503SSERIE

- Page 349 and 350:

Laser Scan Micrometer LSM-512SSERIE

- Page 351 and 352:

LSM-5200 Display UnitSERIES 544 —

- Page 353 and 354:

Laser Scan MicrometerApplication Ex

- Page 355 and 356:

ABSOLUTE Digimatic Scale UnitsSERIE

- Page 357 and 358:

ABSOLUTE Digimatic Scale UnitsSERIE

- Page 359 and 360:

Quill Kit with ABSOLUTE EncoderEasy

- Page 361 and 362:

Linear ScaleLinear Encoder SystemSy

- Page 363 and 364:

AT116 Linear ScalesSERIES 539 — E

- Page 365 and 366:

AT715 Linear ScalesSERIES 539 — A

- Page 367 and 368:

AT212 Linear ScalesSERIES 539 — S

- Page 369 and 370:

ST700 Series Linear ScalesSERIES 57

- Page 371 and 372:

KA CounterSERIES 174 — Standard T

- Page 373 and 374:

PSU-200SERIES 539 — Pulse Signal

- Page 375 and 376:

PJ-A3000SERIES 302 — Vertical Pro

- Page 377 and 378:

PJ-H30SERIES 303 — High Accuracy

- Page 379 and 380:

PV-5110SERIES 304 — Profile Proje

- Page 381 and 382:

PV-600ASERIES 305 — Profile Proje

- Page 383 and 384:

PH-A14SERIES 172 — Profile Projec

- Page 385 and 386:

PH-3515FSERIES 172 — Profile Proj

- Page 387 and 388:

Accessories for Profile ProjectorsS

- Page 389 and 390:

Micrometer Headsfor Profile Project

- Page 391 and 392:

TM-505/510SERIES 176 — Toolmaker'

- Page 393 and 394:

MFSERIES 176 — Measuring Microsco

- Page 395 and 396:

MF-USERIES 176 — High-power Multi

- Page 397 and 398:

Hyper MF/MF-USERIES 176 — High-Ac

- Page 399 and 400:

Accessories for Measuring Microscop

- Page 401 and 402:

QM-Data200SERIES 264 — 2-D Data P

- Page 403 and 404:

Vision UnitSERIES 359 — Vision Sy

- Page 405 and 406:

FS-70SERIES 378 — Microscope Unit

- Page 407 and 408:

VMUSERIES 378 — Video Microscope

- Page 409 and 410:

M Plan Apo for Bright Field Observa

- Page 411 and 412:

BD Plan Apo HR for Bright/Dark Fiel

- Page 413 and 414:

MSM-400SERIES 377 — Stereo Micros

- Page 415 and 416:

MSM-400SERIES 377 — Stereo Micros

- Page 417 and 418:

Pocket MagnifiersSERIES 183FEATURES

- Page 419 and 420:

Surftest SJ-301 / SJ-210SERIES 178

- Page 421 and 422:

Surftest SJ-301 / SJ-210SERIES 178

- Page 423 and 424:

Surftest SJ-400SERIES 178 — Porta

- Page 425 and 426:

Surftest SJ-500/P, SV-2100SERIES 17

- Page 427 and 428:

Surftest SV-3100SERIES 178 — Surf

- Page 429 and 430:

Surftest Extreme SV-3000CNC / SV-M3

- Page 431 and 432:

Surftest Extreme SV-3000CNC+ Vision

- Page 433 and 434:

Formtracer SV-C3100 / SV-C4100SERIE

- Page 435 and 436:

Formtracer Extreme SV-C3000CNC / SV

- Page 437 and 438:

Formtracer CS-3200SERIES 525 — Fo

- Page 439 and 440:

Formtracer Extreme CS-5000CNC / CS-

- Page 441 and 442:

Formtracer Extreme CS-H5000CNC+ Vis

- Page 443 and 444:

Optional Styli for Surface Roughnes

- Page 445 and 446:

Optional Accessories for Automatic

- Page 447 and 448:

Contracer CV-1000 / CV-2000SERIES 2

- Page 449 and 450:

Contracer CV-3100 / CV-4100SERIES 2

- Page 451 and 452:

Contracer Extreme CV-3000CNC / CV-4

- Page 453 and 454:

Optional Arms and Styli for Contour

- Page 455 and 456:

Optional Accessories for Automatic

- Page 457 and 458:

Roundtest RA-10SERIES 211 — Round

- Page 459 and 460:

Roundtest RA-120 / 120PSERIES 211

- Page 461 and 462:

Roundtest RA-220SERIES 211 — Roun

- Page 463 and 464:

Roundtest RA-1400 / RA-1500SERIES 2

- Page 465 and 466:

Roundtest RA-2200AS / DS / AH / DHS

- Page 467 and 468:

Roundtest RA-H5200AS / AHSERIES 211

- Page 469 and 470:

Roundtest ExtremeRA-2200CNC / RA-H5

- Page 471 and 472:

Optional Styli for Roundtest† Int

- Page 473 and 474:

Optional Accessories for RoundtestC

- Page 475 and 476:

Lineup of Hardness Testing Machines

- Page 477 and 478:

HM-101 / 112 / 113 / 122 / 123SERIE

- Page 479 and 480:

HM-211 / 221SERIES 810 — Micro Ha

- Page 481 and 482:

AAV-500SERIES 810 — Automatic Vic

- Page 483 and 484:

HV-112 / 113 / 114 / 115SERIES 810

- Page 485 and 486:

Rockwell hardness scalesPreliminary

- Page 487 and 488:

AR-20, ARK-600 / 601, ATK-600 / 601

- Page 489 and 490:

Optional AccessoriesFor Rockwell/Ro

- Page 491 and 492:

Hardmatic HH-300SERIES 811 — Duro

- Page 493 and 494:

LCoordinate Measuring MachinesCoord

- Page 495 and 496:

Crysta-Apex CSERIES 191 — Standar

- Page 497 and 498:

STRATO-ApexSERIES 355 — High Accu

- Page 499 and 500:

CARBstrato / CARBapexSERIES 355 —

- Page 501 and 502:

Crysta-Plus M443 / 574 / 7106SERIES

- Page 503 and 504:

CMM ProbesTP7MHigh accuracy typeTP2

- Page 505 and 506:

LCoordinate Measuring MachinesCoord

- Page 507 and 508:

QV Apex / Hyper QVSERIES 363 — CN

- Page 509 and 510:

QV HYBRID TYPE1, TYPE3SERIES 365

- Page 511 and 512:

QV ACCELSERIES 363 — CNC Vision M

- Page 513 and 514:

Quick ScopeSERIES 359 — CNC / Man